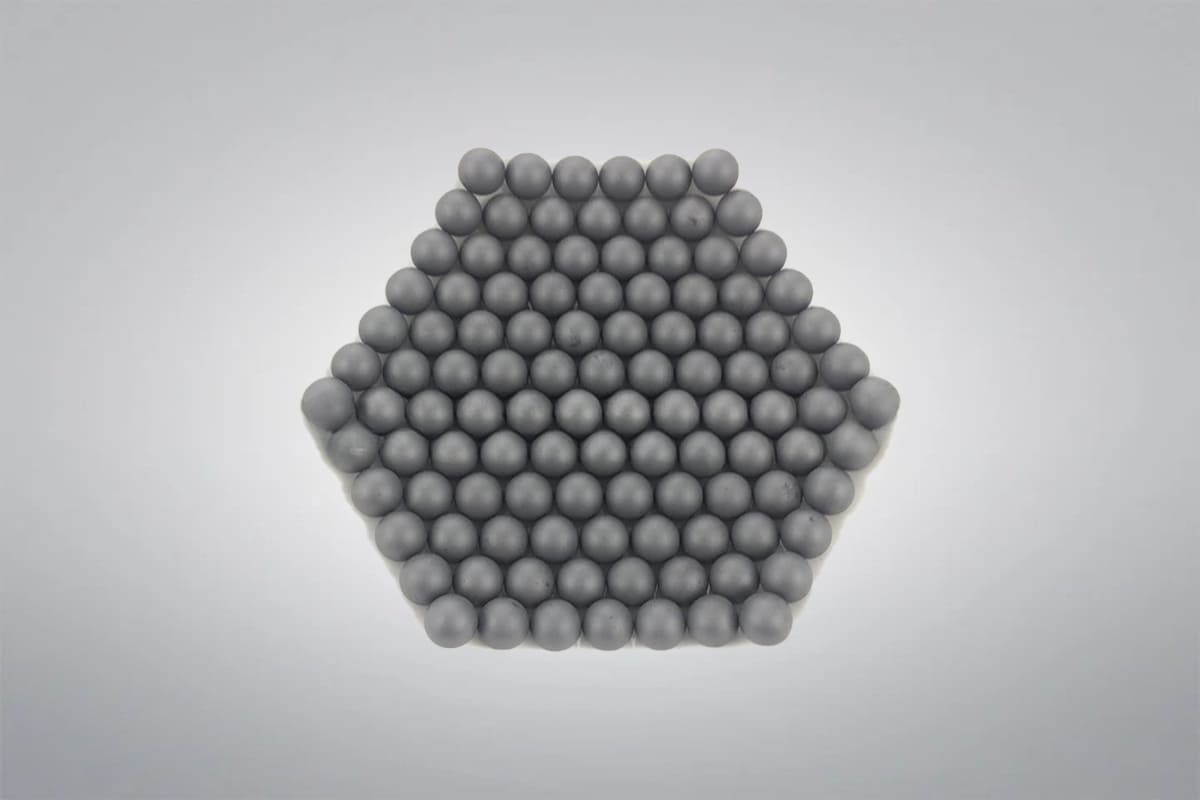

Boron Carbide Ceramic Ball

Boron Carbide Ceramic Ball

Purity: ≥99.5%

Boron Carbide Ceramic Ball is a high-performance ceramic material with low density, exceptional hardness, wear resistance, and thermal stability. It is widely used in abrasive, grinding, and mechanical sealing applications. As a leading supplier and manufacturer of premium boron carbide products, we can supply high-quality boron carbide ceramic balls with various specifications and competitive prices, offering customized solutions to meet specific requirements.

Or email us at sales@heegermaterials.com.Boron Carbide Ceramic Ball Data Sheet

| Purity: | ≥99.5% |

| Apparence: | Black or grey |

| Chemical Formula: | B₄C |

| Density: | 2.46-2.62 g/cm³ |

Boron Carbide Ceramic Ball Description

Boron Carbide is a ceramic material with exceptional hardness close to that of diamond and cubic boron nitride, commonly manufactured through sintering processes. Boron Carbide Ceramic Balls are typically used in high-precision grinding equipment to improve work efficiency and product quality. Due to their high-temperature resistance and corrosion resistance, boron carbide ceramic balls are also extensively used in chemical reactors and the oil and gas industry in high-temperature and highly corrosive environments. Advanced Ceramics Hub manufactures boron carbide ceramic balls with advanced processes, offering precise dimensions, stable performance, and customized solutions for multiple industrial and research applications.

Boron Carbide Ceramic Ball Advantages

- High hardness and high strength

- Excellent thermal shock resistance

- Excellent chemical inertness

- Excellent wear resistance

- Good corrosion resistance

- High temperature resistance

- High bending strength

- Light weight

Boron Carbide Ceramic Ball Pressureless Sintering Process

- Raw Material Preparation: Use high-purity boron carbide powder and sintering aids.

- Powder Mixing: Mix powder and sintering aids evenly.

- Molding: Shape the powder into the desired form.

- Degassing: Remove volatile components to avoid bubbles or cracks.

- Pressureless Sintering: Sinter at 1600-2000°C.

- Cooling and Inspection: Cool to room temperature and inspect for quality.

Boron Carbide Ceramic Ball Applications

- Nuclear Industry: Boron carbide balls are used in nuclear reactors as neutron-absorbing materials to effectively regulate the reaction rate of the reactor.

- Ballistic Protection: Due to their exceptional hardness and resistance to penetration, boron carbide balls are used in ballistic protection systems to enhance defense capabilities.

- Abrasives and Grinding: Boron carbide balls are widely used in the abrasive industry, particularly for precision grinding, polishing, and cutting applications, improving work efficiency and accuracy.

- Chemical Reactors: Boron carbide balls are used as corrosion-resistant and high-temperature materials in chemical reactors, particularly in extreme environments.

- High-Energy Weapons: Boron carbide balls are also used in high-energy weapon systems, as their high hardness enhances the penetrative power of the weapon.

Boron Carbide Material Properties

Boron Carbide Material Grades

Reaction bonded boron carbide (B4C) is primarily used ballistic armor, providing excellent protection while reducing weight as compared to other armor materials.

| Properties | Units | Reaction Bonded Boron Carbide |

| Flexural Strength, MOR (20 °C) | MPa | 250 |

| Fracture Toughness, KIc | MPa m1/2 | 3.0 – 4.0 |

| Thermal Conductivity (20 °C) | W/m K | 50 |

| Coefficient of Thermal Expansion | 1×10-6/°C | 4.5 |

| Maximum Use Temperature | °C | 1000 |

| Dielectric Strength (6.35mm) | ac-kV/mm | — |

| Dielectric Loss (tan δ) | 1MHz, 25 °C | — |

| Volume Resistivity (25°C) | Ω-cm | 10³ |

Reaction Bonded B4C Advantages:

- High strength

- High hardness

- Cost-effective

- Suitable for large-scale applications

Hot-pressed, also known as pressure assisted densified (PAD), boron carbide is one of the hardest materials available in commercial shapes. This exceptional hardness combined with low density is used in ballistic armor, maximizing protection while minimizing weight.

| Properties | Units | Hot Pressed Boron Carbide |

| Flexural Strength, MOR (20 °C) | MPa | 320 – 450 |

| Fracture Toughness, KIc | MPa m1/2 | 3.0 – 4.0 |

| Thermal Conductivity (20 °C) | W/m K | 45 – 100 |

| Coefficient of Thermal Expansion | 1×10-6/°C | 4.5 – 4.9 |

| Maximum Use Temperature | °C | 2000 |

| Dielectric Strength (6.35mm) | ac-kV/mm | — |

| Dielectric Loss (tan δ) | 1MHz, 25 °C | — |

| Volume Resistivity (25°C) | Ω-cm | 100 |

Hot Pressed B4C Advantages:

- Higher density

- Better mechanical properties

- Ideal for high-strength, high-temperature engineering materials

Pressureless sintered boron carbide combines high purity and the excellent mechanical properties of boron carbide for use in both ballistic armor and semiconductor manufacturing.

| Properties | Units | Sintered Boron Carbide |

| Flexural Strength, MOR (20 °C) | MPa | 450 |

| Fracture Toughness, KIc | MPa m1/2 | 3.0 – 5.0 |

| Thermal Conductivity (20 °C) | W/m K | 43 – 100 |

| Coefficient of Thermal Expansion | 1×10-6/°C | 4.5 – 4.9 |

| Maximum Use Temperature | °C | — |

| Dielectric Strength (6.35mm) | ac-kV/mm | — |

| Dielectric Loss (tan δ) | 1MHz, 25 °C | — |

| Volume Resistivity (25°C) | Ω-cm | 10 |

Pressureless Sintered B4C Advantages:

- High hardness

- Excellent wear resistance

- High chemical stability

- Low density

- Good thermal stability

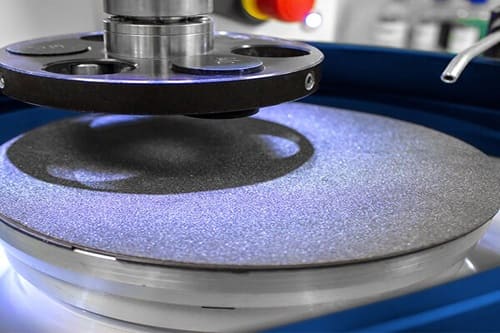

Boron Carbide Ceramic Machining

Boron Carbide Ceramic machining is a demanding process used to shape this ultra-hard ceramic into precise components for technical applications. Due to its exceptional hardness and brittleness, machining boron carbide requires specialized tools and careful control to prevent cracking or surface damage. While the material can be shaped more easily in its green or biscuit state, achieving tight tolerances often requires machining after full sintering, which involves diamond-based techniques. The common machining methods include:

- Diamond Cutting: Diamond-coated tools are essential for cutting fully sintered boron carbide, enabling accurate shaping and smooth surface finishes.

- Precision Grinding: Used to achieve fine tolerances and clean finishes. This process is slow and requires careful handling to avoid micro-cracks or structural damage.

- Ultrasonic Machining: Applies high-frequency vibrations with abrasive slurry to remove material gently, suitable for intricate and delicate shapes.

- Laser Cutting: A non-contact technique effective for pre-sintered material or thin sections, offering clean edges with minimal thermal stress.

- Green Machining: Carried out before sintering, allowing easier shaping of complex geometries. However, post-sintering shrinkage (~20%) must be accounted for in final dimensions.

Boron Carbide Ceramic Packaging

Boron Carbide ceramic products are typically packaged in vacuum-sealed bags to prevent moisture or contamination and wrapped with foam to cushion vibrations and impacts during transport, ensuring the quality of products in their original condition.

Download

Get A Quote

We will check and get back to you in 24 hours.