Zirconia vs. Alumina: Choosing Ceramic Materials for 3D Printing

In 2025, 3D printing has revolutionized manufacturing, and ceramic materials are at the forefront of this transformation. Renowned for their exceptional hardness, thermal stability, and biocompatibility, ceramics like alumina, zirconia, and silicon carbide are unlocking new possibilities in additive manufacturing. From aerospace turbine blades to medical implants and high-performance electronics, 3D-printed ceramics deliver complex geometries and durability that traditional methods struggle to achieve. This blog explores the unique properties of ceramic materials, the latest printing techniques, their diverse applications, and the future of this cutting-edge technology

At Advanced Ceramics Hub, we specialize in high-quality Alumina and Zirconia ceramic products, ensuring optimal performance for industrial and scientific applications.

Why Ceramics for 3D Printing?

Ceramics—long valued for their heat resistance, hardness, and chemical stability—are now revolutionizing 3D printing by enabling complex geometries that were previously impossible with traditional manufacturing. Unlike metals or polymers, technical ceramics like alumina (Al₂O₃), zirconia (ZrO₂), and silicon carbide (SiC) offer unique advantages for aerospace, medical, and energy applications—but why are they becoming a game-changer in additive manufacturing?

Key Reasons Ceramics Are Ideal for 3D Printing:

✅ 1. Extreme Temperature Resistance

- Withstand 1,500°C+ (vs. ~300°C for most plastics)

- Ideal for rocket nozzles, turbine blades, and thermal insulators

| Property | Alumina (Al₂O₃) | Zirconia (ZrO₂) | Silicon Carbide (SiC) | Aluminum Nitride (AlN) | Notes |

| Max Continuous Use Temp | 1,600°C | 1,400°C (Y₂O₃-stabilized) | 1,650°C (inert atm) | 1,200°C (oxidizing) | SiC excels in inert/vacuum environments |

| Thermal Conductivity | 30 W/m·K | 2-3 W/m·K | 120 W/m·K | 170-200 W/m·K | AlN is best for heat dissipation |

| Thermal Expansion (×10⁻⁶/°C) | 8.1 | 10.5 | 4.5 | 4.5 | Low expansion = better thermal shock resistance |

| Thermal Shock Resistance (ΔT before cracking) | 200-250°C | 150-200°C | 400-500°C | 300-350°C | SiC is the clear winner |

| Specific Heat Capacity (J/g·K) | 0.88 | 0.50 | 0.67 | 0.74 | Alumina stores more heat energy |

| Melting Point | 2,072°C | 2,715°C | 2,730°C (decomposes) | 2,200°C | Zirconia/SiC for ultra-high temps |

✅ 2. Biocompatibility & Medical Applications

- Zirconia is widely used in dental crowns & bone implants (no metal allergies)

- Porous ceramic scaffolds for tissue engineering (3D printing allows custom structures)

✅ 3. Superior Wear & Corrosion Resistance

- Harder than most metals (Alumina: ~9 Mohs vs. Steel: ~4.5 Mohs)

- Perfect for chemical reactors, cutting tools, and marine components

| Property | Alumina (Al₂O₃ 99%) | Zirconia (3Y-TZP) | Silicon Carbide (SiC) | Silicon Nitride (Si₃N₄) | Notes |

| Hardness (HV) | 1,600-2,000 | 1,200-1,400 | 2,500-3,000 | 1,600-1,800 | SiC hardest |

| Fracture Toughness (MPa√m) | 3-4 | 9-10 | 3-4 | 6-7 | ZrO₂ most crack-resistant |

| Wear Rate (mm³/Nm×10⁻⁶) | 0.5-2.0 | 0.3-0.8 | 0.1-0.3 | 0.2-0.5 | SiC most wear-resistant |

| Corrosion Resistance | Excellent (pH 1-14) | Good (pH 4-12) | Exceptional (pH 0-14) | Excellent (pH 2-12) | SiC withstands boiling acids |

| Compressive Strength (MPa) | 2,000-3,000 | 2,000-2,500 | 3,500-4,500 | 3,000-3,500 | SiC best for high load |

| Flexural Strength (MPa) | 300-400 | 900-1,200 | 400-600 | 700-900 | ZrO₂ best bending strength |

| Density (g/cm³) | 3.9 | 6.0 | 3.2 | 3.2 | SiC/Si₃N₄ lightest |

✅ 4. Electrical & Thermal Insulation

- Alumina’s high dielectric strength makes it essential for electronics & sensors

- Silicon carbide (SiC) is used in semiconductor & high-power devices

| Property | Alumina (Al₂O₃ 96%) | Zirconia (3Y-TZP) | Aluminum Nitride (AlN) | Silicon Carbide (SiC) | Beryllia (BeO) | Notes |

| Dielectric Strength (kV/mm) | 15-20 | 8-12 | 15-18 | 10-15 | 12-16 | BeO has the lowest signal loss |

| Volume Resistivity (Ω·cm @25°C) | >10¹⁴ | >10¹⁰ | >10¹⁴ | 10²-10⁵ | >10¹⁴ | SiC is semi-conductive |

| Dielectric Constant (1MHz) | 9-10 | 22-29 | 8-9 | 40-50 | 6-7 | Low = better for high-frequency |

| Loss Tangent (1MHz) | 0.0002-0.0005 | 0.01-0.02 | 0.0004-0.0008 | 0.05-0.1 | 0.0001-0.0003 | BeO/AlN is best for heat dissipation |

| Thermal Conductivity (W/m·K) | 30 | 2-3 | 170-200 | 120 | 250-300 | BeO/AlN best for heat dissipation |

| CTE (×10⁻⁶/°C, 20-300°C) | 8.1 | 10.5 | 4.5 | 4.5 | 7.5 | Matches Si (3.5) for electronics |

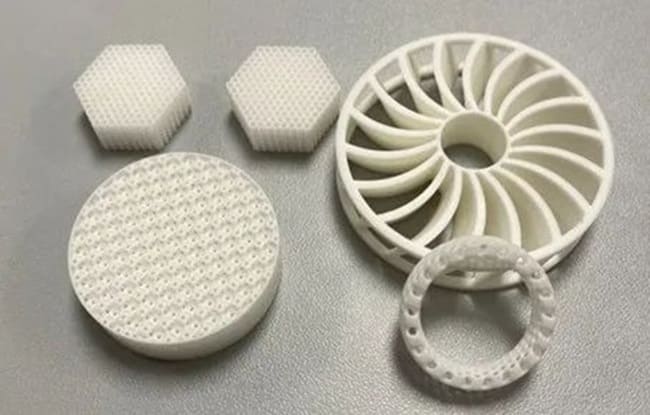

✅ 5. Design Freedom & Lightweighting

- 3D printing enables honeycomb structures, internal channels, and thin walls

- 40-60% weight reduction vs. metal counterparts in aerospace parts

Challenges & Innovations

⚠ Brittleness? → New nano-reinforced ceramics improve toughness

⚠ Hard to Sinter? → Binder jetting & stereolithography (SLA) now achieve >99% density

⚠ Cost? → AI-driven process optimization reduces material waste

Types of Ceramic Materials for 3D Printing

Ceramic materials for 3D printing offer a unique combination of strength, thermal resistance, and versatility, making them ideal for advanced applications. From alumina’s electrical insulation to zirconia’s biocompatibility and silicon carbide’s extreme durability, each ceramic type brings distinct properties to additive manufacturing.

1. Oxide Ceramics

| Material | Key Properties | 3D Printing Methods | Applications |

| Alumina (Al₂O₃) | – High hardness (1600-2000 HV) – Excellent dielectric strength (15-20 kV/mm) – Cost-effective | Binder Jetting, SLA, DLP | Electronics, insulators, wear parts |

| Zirconia (ZrO₂) | – Highest fracture toughness (9-10 MPa√m) – Biocompatible – Moderate thermal conductivity (2-3 W/m·K) | SLA, DLP, FDM (with filaments) | Dental implants, aerospace components |

| Silica (SiO₂) | – Low thermal expansion (0.5×10⁻⁶/°C) – Optical transparency | Powder bed fusion, SLA | Precision optics, microfluidics |

2. Non-Oxide Ceramics

| Material | Key Properties | 3D Printing Methods | Applications |

| Silicon Carbide (SiC) | – Extreme hardness (2500-3000 HV) – Superior thermal shock resistance – Semi-conductive | Binder Jetting, SLS | Turbine blades, nuclear components |

| Silicon Nitride (Si₃N₄) | – High strength (700-900 MPa flexural) – Good fracture toughness (6-7 MPa√m) | SLA, DLP | Bearings, engine parts |

| Aluminum Nitride (AlN) | – Exceptional thermal conductivity (170-200 W/m·K) – Low dielectric loss | Binder Jetting | Heat sinks, RF substrates |

3. Bioactive Ceramics

| Material | Key Properties | 3D Printing Methods | Applications |

| Hydroxyapatite (HAp) | – Osteoconductive – Mimics bone mineral | Extrusion, SLA | Bone scaffolds, dental grafts |

| Tricalcium Phosphate (TCP) | – Biodegradable – Promotes bone growth | Powder-based extrusion | Orthopedic implants |

4. Advanced Composite Ceramics

| Material | Key Properties | 3D Printing Methods | Applications |

| Alumina-Zirconia (ZTA) | – Combines Al₂O₃ hardness + ZrO₂ toughness | SLA, DLP | Cutting tools, joint replacements |

| Carbon Fiber-Reinforced SiC | – Ultra-high strength-to-weight ratio | Binder Jetting | Spacecraft components |

Looking for premium ceramic products? Explore Advanced Ceramic Hub’s selection.

Zirconia vs. Alumina: The Ultimate Guide for 3D Printing Applications

In the realm of advanced ceramic additive manufacturing, zirconia (ZrO₂) and alumina (Al₂O₃) stand as two dominant materials, each offering unique advantages for industrial 3D printing. While alumina boasts exceptional cost-effectiveness and thermal stability (up to 1600°C), zirconia excels in fracture toughness (9-10 MPa√m vs. alumina’s 3-4 MPa√m) and biocompatibility.

- Zirconia 3D Printing Parts

- Alumina 3D Printing Parts

1. Mechanical Performance

| Property | Zirconia (3Y-TZP) | Alumina (96% Al₂O₃) |

| Flexural Strength (MPa) | 900–1,200 | 300–400 |

| Hardness (HV) | 1,200–1,400 | 1,600–2,000 |

| Fracture Toughness (MPa√m) | 9–10 | 3–4 |

| Wear Rate (mm³/N·m×10⁻⁶) | 0.3–0.8 | 0.5–2.0 |

2. Thermal Behavior

| Property | Zirconia | Alumina |

| Melting Point (°C) | 2,715 | 2,072 |

| Max Continuous Use Temp (°C) | 1,400 (Y₂O₃-stabilized) | 1,600 |

| Thermal Conductivity (W/m·K) | 2–3 | 30 |

| Thermal Shock Resistance (ΔT) | 150–200°C | 200–250°C |

3. Printability

| Parameter | Zirconia | Alumina | Winner |

| SLA/DLP Compatibility | Excellent (low light scattering) | Good (requires high-energy lasers) | ZrO₂ |

| Binder Jetting | Challenging (high sintering shrinkage) | Better (lower shrinkage) | Al₂O₃ |

| Layer Resolution (SLA, µm) | 25–50 | 50–100 | ZrO₂ |

| Debinding Time (h) | 8–12 | 6–8 | Al₂O₃ |

4. Post-Processing

| Parameter | Zirconia | Alumina |

| Sintering Temp (°C) | 1,450–1,600 | 1,500–1,700 |

| Linear Shrinkage (%) | 15–20 | 12–15 |

| Density After Sintering (%) | 99.5+ | 99.0+ |

| Surface Finish (Ra, µm) | 0.4–0.8 | 0.2–0.5 |

5. Cost-Benefit Analysis

| Factor | Zirconia | Alumina |

| Material Cost ($/kg) | $80–120 | $20–40 |

| Printing Waste (%) | 10–15 (binder jetting) | 5–10 |

| Recyclability | Limited (contaminated binders) | High (powder reuse) |

| ROI (High-Value Apps) | Medical/Aerospace | Industrial |

Recommendations by Application:

- Dental/Medical Implants → ZrO₂ (biocompatibility + strength)

- Electronics Insulation → Al₂O₃ (dielectric + thermal conductivity)

- Aerospace (High-Temp) → ZrO₂ (melting point)

- Industrial Wear Parts → Al₂O₃ (cost + abrasion resistance)

Explore our high-quality zirconia and alumina ceramic products.

3D Printing Techniques for Ceramics

The versatility of ceramic 3D printing lies in the array of advanced techniques that enable the creation of complex, high-performance components. Methods like Stereolithography (SLA), Binder Jetting, Direct Ink Writing (DIW), and Fused Deposition Modeling (FDM) have revolutionized how ceramics are shaped, offering precision and scalability.

1. Vat Photopolymerization (SLA/DLP)

| Parameter | Details | Best For |

| Process | UV-cures ceramic-loaded resin layer-by-layer | High-detail zirconia/alumina parts |

| Resolution | 25–50 µm (DLP), 10–100 µm (SLA) | Dental crowns, microfluidics |

| Materials | ZrO₂, Al₂O₃, HAp (≤60 vol% ceramic loading) | |

| Pros | – Smooth surface finish (Ra < 0.5 µm) – Complex geometries | |

| Cons | – Requires debinding/sintering – Limited to small builds (<150 mm) | |

| Post-Processing | Thermal debinding (300–600°C) + sintering (1400–1600°C) |

2. Binder Jetting

| Parameter | Details | Best For |

| Process | Binds ceramic powder layers with liquid binder | Large industrial components |

| Resolution | Binds ceramic powder layers with a liquid binder | SiC furnace parts, insulators |

| Materials | Al₂O₃, SiC, ZrO₂ (wide material range) | |

| Pros | – No supports needed – Scalable to meters | |

| Cons | – Low green strength – Requires infiltration (e.g., silica) | |

| Post-Processing | Infiltration + sintering (shrinkage ~15–20%) |

3. Material Extrusion (FDM/DIW)

| Parameter | Details | Best For |

| Process | Extrudes ceramic-filled filaments/pastes | Prototypes, porous scaffolds |

| Resolution | 100–500 µm | Bone grafts, custom tooling |

| Materials | Al₂O₃, ZrO₂, TCP (50–70% ceramic in polymer binder) | |

| Pros | – Low-cost equipment – Multi-material possible | |

| Cons | – High porosity (~30%) – Rough surface (Ra > 10 µm) | |

| Post-Processing | Debinding (250–500°C) + sintering (shrinkage up to 25%) |

4. Powder Bed Fusion (SLS/SLM)

| Parameter | Details | Best For |

| Process | Laser sintered ceramic powder beds | High-performance SiC/Si₃N₄ parts |

| Resolution | Laser-sintered ceramic powder beds | Turbine blades, aerospace |

| Materials | SiC, AlN, Si₃N₄ (requires high-power lasers) | |

| Pros | – No binders needed – Good mechanical properties | |

| Cons | – Limited material options – High equipment cost | |

| Post-Processing | Minimal (direct near-net-shape) |

5. Sheet Lamination (LOM)

| Parameter | Details | Best For |

| Process | Bonds ceramic green tapes with laser/adhesive | Large flat components |

| Resolution | 200–500 µm | Electronics substrates |

| Materials | Al₂O₃, LTCC (low-temp co-fired ceramic) | |

| Pros | – Fast build rates – Low residual stress | |

| Cons | – Limited geometry complexity – Poor surface finish | |

| Post-Processing | Laser trimming, lamination (for multilayer PCBs) |

Technical Comparison by Industry

| Technique | Resolution | Material Options | Strength (MPa) | Surface Finish (Ra) | Best Applications |

| SLA/DLP | 10–50 µm | ZrO₂, Al₂O₃ | 900–1,200 | 0.2–0.5 µm | Dental, microelectronics |

| Binder Jetting | 50–200 µm | Al₂O₃, SiC | 200–400 | 3–5 µm | Industrial wear parts |

| FDM/DIW | 100–500 µm | ZrO₂, TCP | 50–150 | 10–20 µm | Biomedical scaffolds |

| SLS/SLM | 30–100 µm | SiC, Si₃N₄ | 400–600 | 1–2 µm | Aerospace components |

| Sheet Lamination | 200–500 µm | Al₂O₃, LTCC | 100–200 | 5–10 µm | Electronic substrates |

Request a custom quote for high-quality alumina and zirconia ceramic products.

Applications of 3D-Printed Ceramics

3D printed ceramics are revolutionizing industries by enabling complex geometries, high-temperature resistance, and biocompatibility unachievable with traditional manufacturing. Below is a technical overview of key applications, categorized by sector:

1. Medical & Dental

- Dental Crowns/Bridges (ZrO₂, SLA/DLP)

- Bone Scaffolds (HAp/β-TCP, DIW)

- Surgical Tools (Al₂O₃, FDM)

- Hearing Aid Components (ZrO₂, SLA)

2. Aerospace & Defense

- Turbine Blades (SiC/Si₃N₄, SLS)

- Radome Windows (SiO₂-Al₂O₃, Binder Jetting)

- Heat Shields (Porous ZrO₂, SLA)

- Satellite Antennas (AlN, DIW)

3. Energy & Electronics

- Solid Oxide Fuel Cells (SOFCs) (8YSZ, DIW)

- Battery Electrolytes (LLZO, SLA)

- Heat Sinks (AlN, Binder Jetting)

- Power Electronics Insulators (Al₂O₃, FDM)

4. Industrial & Tooling

- Cutting Tools (Al₂O₃-TiC, Binder Jetting)

- Chemical Reactor Liners (SiC, SLS)

- Wear-Resistant Nozzles (ZrO₂, SLA)

- Industrial Sensors (PZT, DIW)

Challenges and Limitations of Ceramic 3D Printing

While ceramic 3D printing enables groundbreaking applications, it faces significant hurdles in materials, processes, and economics. Key challenges include limited printable ceramic formulations, high defect rates during sintering, slow production speeds, and costs that remain prohibitive for mass production. Post-processing complexities like warpage control and surface finishing further limit adoption. Below is a concise breakdown of the major limitations:

1. Material Limitations

- Narrow material selection (only ~20 printable ceramics vs. 100+ metals/polymers)

- Particle size sensitivity (agglomeration risks in slurries/powders)

- Binder-ceramic compatibility issues (debinding cracks, shrinkage >15%)

2. Process Challenges

- Low green strength (fragile pre-sintered parts, >10% scrap rates)

- Slow print speeds (5–50 cm³/hr vs. 100+ cm³/hr for metals)

- Resolution-scalability trade-off (high-res SLA limits part size <150 mm)

3. Post-Processing Hurdles

- Sintering defects (warpage, anisotropic shrinkage)

- Surface roughness (Ra 5–15 µm for binder jetting vs. <0.5 µm for SLA)

- Density limitations (often requires HIP to reach >99% density)

4. Economic Barriers

- High material costs (ZrO₂ powder: $80–120/kg vs. $20–40/kg conventional)

- Low throughput (<10 parts/job vs. 100s via injection molding)

- Certification delays (6–12 months for medical/aerospace approvals)

5. Application-Specific Issues

- Medical: Sterilization compatibility risks

- Aerospace: No repairability for cracked parts

- Electronics: Dielectric property consistency challenge

Ceramic 3D printing stands as a transformative force in 2025, blending the exceptional properties of materials like alumina, zirconia, and silicon carbide with the precision of additive manufacturing. From crafting intricate aerospace components to producing biocompatible medical implants, ceramics enable complex geometries and high performance that redefine industry standards. Despite challenges like high material costs and complex post-processing, the innovation potential is immense. As advancements in printing techniques and sustainable practices continue to evolve, ceramic 3D printing is poised to drive breakthroughs across sectors. Businesses and researchers are encouraged to explore this technology, partnering with experts to unlock its full potential for innovative, high-value solutions.

Looking for premium ceramic heaters? Contact us today!