What Role Does BeO Compound Play In Electronic Components?

Beryllium oxide (BeO compound) has established itself as one of the most critical advanced ceramics used in modern electronics. With its exceptional combination of high thermal conductivity, electrical insulation, and mechanical strength, the BeO compound is uniquely positioned to solve challenges that traditional ceramics, such as alumina or zirconia, cannot. In electronic components, the ability to dissipate heat without compromising electrical insulation is vital, especially as devices become smaller, faster, and more powerful. This article explores the role of BeO compound in electronic components, from its material properties to its applications, comparisons with other ceramics, and its advantages in next-generation technologies. The discussion will also highlight how the BeO compound compares with alternative materials and why its properties make it indispensable for specialized high-performance systems.

At Advanced Ceramics Hub, we specialize in high-quality BeO products, ensuring optimal performance for industrial and scientific applications.

What Is BeO Compound And Why Is It Important In Electronics?

BeO compound is a ceramic material composed of beryllium and oxygen, forming a crystalline oxide with unique characteristics. Unlike many ceramics that offer either good thermal conductivity or electrical insulation, BeO compound provides both, making it particularly valuable in electronics. Its thermal conductivity rivals that of metals such as aluminum, while its insulating properties remain as strong as traditional ceramics. This dual functionality allows BeO substrates and packaging materials to manage heat effectively in high-power devices while maintaining electrical isolation.

Key Characteristics of BeO Compound in Electronics:

| Property | BeO Compound | Al2O3 | SiC | ZrO2 |

| Thermal Conductivity (W/m·K) | 330–370 | 25–35 | 120–150 | 2–3 |

| Electrical Resistivity (Ω·cm) | 1 × 10^14 | 1 × 10^12 | 1 × 10^3–10^5 | 1 × 10^12 |

| Dielectric Strength (kV/mm) | 14–16 | 12–14 | 10–12 | 10–12 |

| Max Operating Temp (°C) | 1000 | 1200 | 1600 | 1500 |

These properties explain why the BeO compound has become essential in electronics, particularly for power semiconductors, microwave devices, and laser diodes, where both heat dissipation and insulation are critical.

Explore our high-quality BeO ceramic products.

How Does BeO Compound Improve Thermal Management In Electronic Devices?

One of the biggest challenges in electronics is managing heat. High-density circuits and power devices generate significant thermal loads, and failure to dissipate this heat can reduce efficiency, shorten lifespan, or even damage components. BeO compound addresses this challenge with its extremely high thermal conductivity, which is more than ten times greater than alumina, the most common ceramic substrate.

Thermal Performance Comparison:

| Material | Thermal Conductivity (W/m·K) | Application Efficiency |

| BeO Compound | 330–370 | Excellent heat dissipation, reliable for high-power modules |

| Al2O3 | 25–35 | Moderate, suitable for low to medium-power electronics |

| SiC | 120–150 | Good, but not electrically insulating |

| ZrO2 | 2–3 | Poor for heat transfer, better for mechanical toughness |

By using BeO compound substrates, electronic devices can operate at higher power densities without overheating, leading to improved performance, greater reliability, and longer service life. This role is particularly important in fields such as RF amplifiers, high-power transistors, and aerospace electronics.

What Electrical Advantages Does BeO Compound Offer?

BeO compound is not only thermally conductive but also an excellent electrical insulator. This property is crucial in electronics, where circuits must be protected from electrical leakage while still allowing for efficient heat transfer. BeO’s dielectric strength ensures that it can withstand high voltages without breakdown, which is essential in applications such as power amplifiers and laser diodes.

Electrical Property Comparison:

| Property | BeO Compound | Al2O3 | Si3N4 |

| Dielectric Constant | 6.7–7.0 | 9.8 | 7–8 |

| Resistivity (Ω·cm) | 1 × 10^14 | 1 × 10^12 | 1 × 10^13 |

| Dielectric Strength (kV/mm) | 14–16 | 12–14 | 10–12 |

This combination of high resistivity and low dielectric constant makes the BeO compound ideal for microwave and RF applications, where signal integrity and minimal energy loss are required. Unlike silicon carbide, which is partially conductive, the BeO compound maintains complete insulation, providing a clear advantage for electronic packaging.

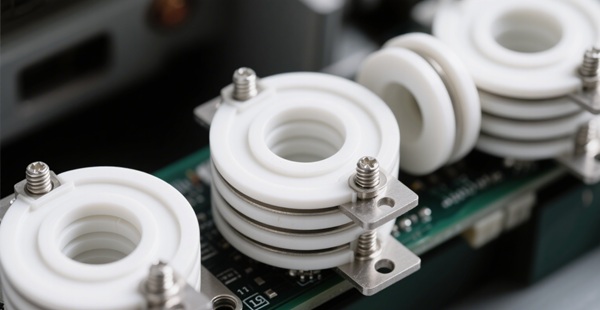

How Is BeO Compound Used In Electronic Packaging And Substrates?

Electronic packaging materials must fulfill two major requirements: protecting delicate circuits from environmental stress and ensuring efficient heat removal. BeO compound substrates and heat sinks have become widely adopted for these reasons. They allow designers to pack more power into smaller spaces while maintaining reliability.

Applications of BeO Compound in Packaging:

- Substrates for high-power transistors – manage thermal loads efficiently.

- Laser diode mounts – prevent overheating while maintaining insulation.

- RF amplifier bases – support high-frequency performance.

- Insulating heat sinks – combine mechanical strength with thermal efficiency.

- Hybrid circuits – allow compact integration of power and signal components.

These applications highlight how the BeO compound directly addresses the thermal and electrical challenges in next-generation electronics.

How Does BeO Compound Compare With Other Ceramics In Electronics?

Although several ceramics are available for electronics, such as Al2O3, SiC, and AlN (aluminum nitride), the BeO compound maintains unique advantages. Al2O3 is cheap and common but has poor thermal conductivity. SiC and AlN have higher conductivity but either lack insulation (SiC) or are more expensive and less stable at high temperatures (AlN).

Ceramic Material Comparison in Electronics:

| Material | Thermal Conductivity | Electrical Insulation | Cost | Application Suitability |

| BeO Compound | Excellent | Excellent | High | High-power electronics, aerospace |

| Al2O3 | Low | Good | Low | General substrates, low-power circuits |

| SiC | High | Limited | Medium | Mechanical and thermal parts |

| AlN | High | Good | High | Advanced electronics, less stable at extremes |

From this comparison, the BeO compound stands out as the most balanced option for high-performance electronic systems where both heat management and electrical insulation are non-negotiable.

Request a custom quote for BeO ceramic products.

What Are The Main Electronic Applications Of the BeO Compound?

The unique properties of the BeO compound have led to its adoption in several specialized electronic applications. These include areas where performance and reliability are critical under demanding conditions.

Applications of BeO Compound in Electronics:

| Application | Role of BeO Compound | Benefit |

| Power Electronics | Substrates for high-power devices | Enhanced thermal management |

| RF & Microwave Devices | Packaging and bases | Low signal loss + insulation |

| Optoelectronics | Laser diode mounts | Heat dissipation + stability |

| Aerospace Electronics | High-temperature circuits | Reliability under extreme conditions |

| Nuclear Electronics | Radiation-resistant components | Long-term durability |

BeO compound has therefore become indispensable in industries where both efficiency and durability define success.

What Advantages Does BeO Compound Bring To Future Electronic Technologies?

With the rapid advancement of semiconductor technologies, the demand for materials that can handle greater thermal loads while maintaining electrical stability is only increasing. BeO compound’s combination of properties positions it as a future-proof material. Potential uses include next-generation power modules, 5G communication systems, and compact energy devices.

Advantages of BeO Compound in Emerging Electronics:

- Enables miniaturization by handling higher power densities.

- Improves the reliability of high-frequency communication systems.

- Ensures stability in extreme aerospace and defense environments.

- Offers long-term performance with reduced failure rates.

- Provides a competitive edge over other ceramics in specialized applications.

The growing demand for high-efficiency and durable electronics means BeO compound will likely remain a cornerstone material in advanced component design.

FAQ

| Question | Answer |

| Why is BeO compound preferred in electronic substrates? | It combines high thermal conductivity with electrical insulation, unlike most other ceramics. |

| What are the safety concerns when handling BeO compound? | BeO powder is toxic if inhaled; safe processing and encapsulation are required. |

| How does the BeO compound compare with AlN in electronics? | Both offer high conductivity, but the BeO compound has better stability under extreme conditions. |

| Is the BeO compound more expensive than Al2O3? | Yes, but its performance justifies the cost in high-power and critical applications. |

| Can the BeO compound be used in consumer electronics? | It is mainly reserved for high-performance devices due to cost and handling precautions. |

| What industries use the BeO compound the most? | Aerospace, defense, telecommunications, and power electronics. |

| How does the BeO compound improve device lifespan? | By preventing overheating and reducing thermal stress on components. |

| Does BeO compound replace metals in electronics? | No, it complements them by providing insulation while offering metallic-level conductivity. |

| What is the maximum working temperature of the BeO compound? | Around 1000°C, making it suitable for high-temperature electronics. |

| Why is the BeO compound important in RF and microwave circuits? | Its low dielectric constant reduces signal losses while managing heat. |

Conclusion

BeO compound plays a unique and critical role in electronic components, offering unmatched thermal conductivity, excellent electrical insulation, and robust mechanical stability. Its properties allow engineers to design more powerful, reliable, and compact electronic devices, especially in high-performance sectors such as aerospace, telecommunications, and power electronics. Compared with traditional ceramics like Al2O3 or advanced alternatives like AlN and SiC, the BeO compound consistently stands out as the most balanced material for managing both heat and electrical demands. As electronics continue to advance toward higher power densities and faster communication speeds, BeO compound will remain an essential ceramic material shaping the future of technology.

Looking for high-quality BeO ceramic products? Contact us today!