What is the Role of Activated Alumina in Catalysis?

Activated alumina is an essential material in the field of catalysis due to its significant role in various industrial processes. Catalysts are substances that increase the rate of chemical reactions without being consumed, and activated alumina serves as both a catalyst and a catalyst support. In this article, we will explore how activated alumina is used in catalysis, its properties, its applications, and its mechanisms, to understand why it is so widely employed in numerous catalytic reactions.

At Advanced Ceramics Hub, we specialize in high-quality alumina ceramic products with various forms and specifications, ensuring optimal performance for industrial and scientific applications.

What is Activated Alumina?

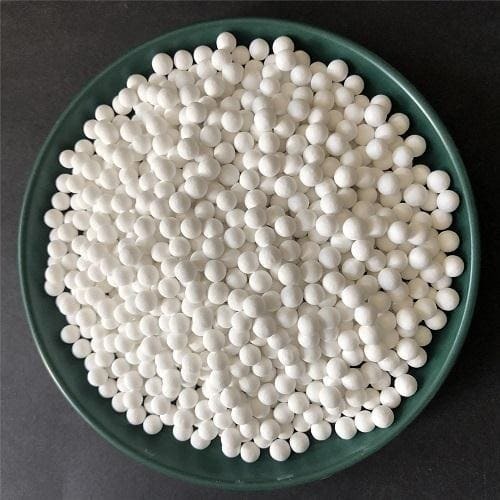

Activated alumina, a highly porous form of aluminum oxide (Al₂O₃), is a versatile material widely used in industrial and scientific applications due to its unique physical and chemical properties. It is produced through the controlled dehydration of aluminum hydroxide, resulting in a material with a high surface area, typically ranging from 150 to 300 m²/g, and a complex network of pores. This structure makes activated alumina an ideal candidate for catalysis, where surface interactions are critical. Its ability to act as a catalyst support, direct catalyst, or adsorbent underscores its importance in processes ranging from petrochemical refining to environmental protection.

The material’s appeal lies in its cost-effectiveness, durability, and ability to withstand harsh chemical and thermal environments. Unlike other forms of alumina, activated alumina is engineered to maximize its surface area and porosity, which are essential for catalytic applications. For example, in catalysis, the high surface area provides ample space for active catalytic sites, while the pores facilitate the diffusion of reactants and products. This makes activated alumina a cornerstone in industries seeking efficient and sustainable chemical processing solutions.

Looking for high-quality alumina ceramic products? Explore Advanced Ceramics Hub’s selection.

What Are the Properties of Activated Alumina?

Activated alumina, a highly porous form of aluminum oxide (Al₂O₃), is renowned for its exceptional physical and chemical properties, making it a critical material in catalysis, adsorption, and industrial applications. Its high surface area, tunable porosity, chemical stability, and unique surface chemistry enable it to serve as an effective catalyst support, direct catalyst, or adsorbent.

1. High Surface Area

The hallmark of activated alumina is its exceptionally high surface area, typically ranging from 150 to 300 m²/g, which is critical for its role in catalysis. This large surface area provides numerous active sites for catalytic reactions, allowing more reactant molecules to interact with the catalyst simultaneously. For instance, in hydrotreating processes, the high surface area ensures that metal catalysts like nickel or molybdenum are well-dispersed, maximizing their contact with hydrocarbons and improving reaction efficiency.

The surface area is a direct result of the material’s porous structure, created during the dehydration process. This structure is often characterized using the Brunauer-Emmett-Teller (BET) method, which quantifies the surface available for adsorption and catalysis. The benefits of high surface area include:

- Increased Catalytic Activity: More sites for reaction initiation.

- Improved Dispersion: Better distribution of active catalytic phases.

- Enhanced Efficiency: Higher yields in less time due to greater reactant-catalyst interaction.

2. Porosity and Pore Structure

Activated alumina’s porosity, characterized by a network of micro- and mesopores, is another key attribute for catalysis. These pores, typically ranging from 2 to 50 nm in diameter, facilitate the diffusion of reactants to active sites and the removal of products, preventing blockages that could reduce efficiency. The pore structure can be tailored during synthesis to optimize performance for specific reactions, such as the Claus process for sulfur recovery, where large pores are needed to accommodate bulky molecules.

The pore structure impacts several catalytic properties:

- Accessibility: Pores allow reactants to reach deep within the material.

- Selectivity: Pore size can influence which molecules can enter and react.

- Mass Transfer: Efficient diffusion reduces reaction bottlenecks.

| Pore Type | Size Range | Catalytic Benefit |

| Micropores | < 2 nm | High selectivity for small molecules |

| Mesopores | 2–50 nm | Balance of accessibility and surface area |

| Macropores | > 50 nm | Enhanced diffusion for large molecules |

3. Chemical Stability

Activated alumina’s chemical stability enables it to withstand harsh environments, such as high temperatures (up to 1000°C) and corrosive chemicals, making it ideal for demanding catalytic applications. This stability ensures that the material retains its structure and functionality over prolonged use, reducing the need for frequent catalyst replacement. For example, in catalytic converters, activated alumina maintains its integrity despite exposure to exhaust gases containing sulfur compounds and high temperatures.

This stability is attributed to the strong Al-O bonds in its crystal lattice, which resist degradation under acidic or basic conditions. Key aspects include:

- Thermal Resistance: Maintains structure at high temperatures.

- Chemical Inertness: Resists reactions with aggressive chemicals.

- Longevity: Extends catalyst lifespan, reducing operational costs.

4. Thermal Stability (Up to 500–1000°C)

Activated alumina exhibits exceptional thermal stability, maintaining its structural integrity and porosity at temperatures ranging from 500°C to 1000°C. This property ensures minimal sintering or degradation under high-temperature catalytic processes (e.g., hydrocracking, steam reforming). Its resistance to thermal deactivation allows for prolonged catalyst life and consistent performance in demanding industrial applications, even in oxidative or steam-rich environments.

- Maintains structural integrity in high-temperature reactions (e.g., steam reforming, hydrocracking).

- Resists sintering (grain growth) better than silica or carbon supports.

5. Surface Acidity/Basicity

The surface of activated alumina is rich in hydroxyl groups and Lewis acid sites, which play a pivotal role in catalysis. Hydroxyl groups provide anchoring points for impregnating active catalytic phases, such as metals or oxides, ensuring strong bonding and uniform dispersion. Lewis acid sites contribute to catalytic activity by facilitating acid-base interactions, which are crucial in reactions like alcohol dehydration or hydrocarbon isomerization.

The surface chemistry can be modified to enhance performance, for example, by adjusting the density of acid sites or introducing dopants like silica or zirconia. This tunability makes activated alumina versatile for various catalytic roles, from supporting noble metal catalysts to acting as a standalone catalyst in specific reactions.

- Lewis Acid Sites (Al³⁺ centers): Can directly catalyze reactions like dehydration, isomerization, and alkylation.

- Modifiable Surface: Acidic/basic properties can be tuned via doping (e.g., with Cl⁻, F⁻, or alkali metals).

5. Mechanical Strength & Abrasion Resistance

Activated alumina exhibits high mechanical strength and excellent abrasion resistance, making it ideal for demanding catalytic and adsorption applications. Its robust structure prevents crushing in high-pressure reactors (e.g., fixed-bed systems) and minimizes attrition in fluidized-bed processes. These properties ensure long-term durability, reducing catalyst breakdown and operational downtime.

- Withstands high-pressure conditions (e.g., in fixed-bed reactors).

- Resists attrition in fluidized-bed catalytic processes.

Explore our optimized alumina ceramic products.

What Are the Applications of Activated Alumina in Catalysis?

Activated alumina is widely used as a catalyst support and sometimes as a catalyst itself due to its tunable surface properties, thermal stability, and mechanical strength. Below are key catalytic applications:

✅ Catalyst Support:

Activated alumina is commonly used as a support material for various catalysts. In this role, it serves as a substrate that provides mechanical strength and a large surface area for active catalyst components to be deposited. Its stability under harsh conditions, such as high temperature and pressure, makes it ideal for supporting catalysts in processes such as hydrogenation, dehydrogenation, and cracking.

- In a catalytic converter, activated alumina can be used to support precious metals like platinum or palladium, which are essential for catalyzing reactions.

✅ Hydroprocessing and Refining:

In the refining industry, activated alumina is extensively used in processes like hydrocracking, hydrotreating, and desulfurization. It can adsorb sulfur and nitrogen compounds from petroleum products, thus preventing catalyst poisoning and improving the efficiency of hydroprocessing reactions.

- Activated alumina is used to remove sulfur from gasoline and diesel, which helps reduce the environmental impact of fuel consumption.

✅ Environmental Catalysis:

Activated alumina plays a significant role in environmental protection. It is used in the removal of pollutants from exhaust gases and water treatment. In environmental catalysis, activated alumina can help reduce harmful emissions by supporting catalysts that remove carbon monoxide (CO), nitrogen oxides (NOx), and hydrocarbons (HC) from vehicle exhausts. Furthermore, it is employed in the treatment of wastewater, where it helps remove heavy metals and other contaminants.

✅ Production of Fine Chemicals:

Activated alumina is also utilized in the production of fine chemicals, particularly in reactions involving alkylation, isomerization, and other organic transformations. In these processes, it supports catalysts that help produce valuable chemicals like synthetic fuels, pharmaceuticals, and plastics. The ability of activated alumina to activate molecules and enhance reaction rates makes it a valuable tool in the chemical industry.

Mechanism of Activated Alumina in Catalysis

Adsorption and Desorption

One of the fundamental mechanisms by which activated alumina contributes to catalysis is through adsorption and desorption. Activated alumina has a large surface area and numerous porous structures, which enable it to adsorb reactants onto its surface. The adsorbed molecules are then activated and undergo chemical reactions. After the reaction, the products desorb from the surface, allowing the material to continue catalyzing the next cycle of reactions.

Activated alumina’s catalytic activity begins with the adsorption of reactants onto its porous surface:

- High Surface Area (200–400 m²/g): Provides abundant sites for molecular adsorption.

- Pore Structure: Mesopores (2–50 nm) facilitate diffusion and trapping of reactants.

- Activation of Adsorbates: Polar molecules (e.g., H₂O, alcohols) bind to surface –OH groups or Al³⁺ sites, weakening their bonds for subsequent reactions.

- Desorption of Products: After reaction, weaker product-surface interactions allow release, regenerating active sites (e.g., H₂O desorption in dehydration).

Acidity and Basicity

Activated alumina often contains surface hydroxyl groups, which contribute to its acidic or basic properties. The acidity or basicity of activated alumina influences its ability to catalyze different types of reactions. Acidic sites are useful in processes like alkylation and isomerization, where electron-rich species are involved. Basic sites, on the other hand, are beneficial for reactions like transesterification and nucleophilic substitution.

The surface chemistry of activated alumina dictates its catalytic function:

✅ Acidic Sites:

- Lewis Acidity (Al³⁺): Electron-poor sites polarize π-bonds (e.g., C=C in alkenes) for alkylation or cracking.

- Brønsted Acidity (–OH): Proton donation enables carbocation formation (e.g., isomerization of xylenes).

✅ Basic Sites (O²⁻):

- Deprotonate acidic molecules (e.g., methanol in transesterification).

✅ Tunability:

- Acidity ↑: Halogen doping (Cl⁻) or sulfation (SO₄²⁻).

- Basicity ↑: Alkali metal addition (e.g., K⁺).

Formation of Active Sites

The active sites on activated alumina are crucial for catalytic activity. These sites are often formed during the activation process when aluminum oxide is heated at high temperatures, leading to the creation of microstructures that act as sites for chemical reactions. These sites interact with reactants, enabling the breakdown or formation of chemical bonds. The density and distribution of active sites can significantly affect the catalyst’s efficiency and selectivity.

Active sites are engineered during synthesis/activation:

- Thermal Treatment: Heating (300–700°C) removes –OH groups, exposing Al³⁺ Lewis sites.

- Defect Engineering: Oxygen vacancies (e.g., via reduction) create redox-active sites for CO oxidation.

- Metal Loading: Impregnation with Pt/Pd forms metal-support interfaces for hydrogenation.

- Dopants: Adding CeO₂ enhances oxygen mobility for oxidation reactions.

Factors Affecting the Performance of Activated Alumina Catalysts

✅ Particle Size and Surface Area:

The performance of activated alumina as a catalyst or catalyst support is heavily influenced by its particle size and surface area. Smaller particles offer a higher surface area, which provides more active sites for reactions. However, excessively small particles may lead to issues like sintering or loss of surface area during high-temperature reactions. The ideal particle size depends on the specific catalytic process and the type of reactions involved.

- High surface area (typically 200-400 m²/g) provides more active sites for catalytic reactions

- Surface area is inversely proportional to particle size – smaller particles yield higher surface area

- Mesoporous structure (2-50 nm pores) enables efficient reactant diffusion

✅ Impurities and Contaminants:

The presence of impurities in activated alumina can significantly affect its catalytic performance. Impurities may block active sites, reduce surface area, or poison the catalyst, thereby decreasing its efficiency. For instance, certain metals or sulfur compounds can adsorb onto the alumina surface, leading to deactivation of the catalyst. Proper purification of activated alumina is necessary to ensure consistent catalytic activity.

- Sulfur compounds: Poison metal sites (e.g., deactivate Pt/Al₂O₃)

- Heavy metals (Pb, As): Irreversibly block active sites

- Silica/Sodium: Reduce surface area and acidity

✅ Temperature and Pressure:

Activated alumina catalysts are sensitive to temperature and pressure conditions. High temperatures can accelerate reactions but may also cause the loss of surface area or the destruction of active sites. Similarly, excessive pressure can alter the physical properties of the material, affecting the overall catalytic process. Optimal temperature and pressure conditions must be maintained to maximize the efficiency of activated alumina catalysts in industrial processes.

Request a custom quote for high-quality alumina ceramic products.

What Are the Advantages of Activated Alumina in Catalysis?

- High Thermal Stability: Maintains structural integrity and performance at elevated temperatures, up to 1000°C, ensuring reliability in high-temperature catalytic processes like reforming or oxidation.

- High Chemical Stability: Resists degradation in harsh chemical environments, such as acidic or basic conditions, extending catalyst lifespan in applications like hydrotreating or sulfur recovery.

- Cost-Effectiveness: Benefits from the abundance of aluminum resources, making it an economical choice compared to more expensive supports like zeolites or carbon-based materials.

- Versatility: Supports a wide range of catalytic processes, from petrochemical refining (e.g., hydrocracking) to environmental applications (e.g., catalytic converters), due to its adaptable surface and structural properties.

At Advanced Ceramics Hub, we supply optimized-grade ceramic products that comply with ASTM and ISO standards, ensuring outstanding quality and reliability.

Activated alumina is a versatile material in catalysis, serving as a catalyst support, direct catalyst, and adsorbent. Its high surface area, porosity, and stability make it indispensable in processes like hydrotreating, sulfur recovery, and emission control. By facilitating efficient and durable catalytic reactions, it plays a critical role in modern industrial applications.

In industries ranging from petrochemicals to environmental management, activated alumina contributes to cleaner, more efficient, and cost-effective processes. Its adaptability to emerging applications, such as green chemistry and CO₂ conversion, positions it as a key material in the transition to sustainable technologies.

The potential of activated alumina in catalysis is vast, but continued research and innovation are needed to overcome its limitations and expand its applications.

For top-quality advanced ceramic materials, Advanced Ceramics Hub provides tailored solutions for various applications.

Looking for premium alumina ceramic materials? Contact us today!