Unveiling the Phenomenon of “Inverse Densification” in Materials Sintering: Why Sometimes Does the Green Body Expand?

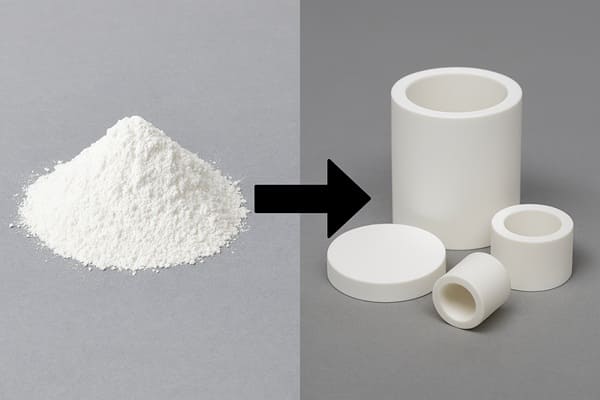

In materials sintering is a crucial process used to produce ceramics, metals, and other advanced materials. Typically, during sintering, we expect the green body (unsintered compact) to become increasingly dense and hard over time. This is because, as sintering progresses, gases are expelled, and grains gradually coalesce, forming a tightly bonded structure.

However, sometimes the opposite occurs— the green body actually expands and becomes less dense. This counterintuitive phenomenon is known as “inverse densification” or “anti-densification.” You might wonder: why does this abnormal behavior happen? What mechanisms drive this process?

At Advanced Ceramics Hub, we specialize in high-quality ceramic products, utilizing a diverse range of materials and specifications to ensure optimal performance for industrial and scientific applications.

What is “Inverse Densification”?

Inverse densification refers to the decrease in density during the sintering process, resulting in material expansion. A typical example is the sintering of copper powder in a hydrogen atmosphere. Studies have shown that when copper powder is sintered at 900°C in hydrogen, the density increases during the first six hours, but after that, it begins to decline, from approximately 8.0 g/cm³ down to about 7.6 g/cm³.

Similar phenomena have been observed in other materials, such as Fe-Cu alloys during hydraulic sintering with 10% copper, zinc oxide (ZnO) during hot pressing, and certain superconducting ceramics.

So, why does this “anomalous” behavior occur? Research has identified several mechanisms behind inverse densification.

1. Gas Pressure and Pore Expansion (“Pore Blowing”)

In the final stages of sintering, closed pores (enclosed gas cavities) within the green body are influenced by internal gas pressure. According to a basic model, if the gas pressure inside a pore exceeds the surface tension-induced Laplace pressure (2γ/r), the pore will expand rather than shrink, leading to a decrease in overall density.

In other words, as pores grow larger, the internal gas pressure can cause them to swell, counteracting the densification process. This effect becomes more pronounced as pore size increases.

2. Mismatch in Solubility of Solid-Liquid and Liquid-Solid Phases

In some sintering processes, a liquid phase appears, such as in liquid-phase sintering of copper or certain ceramics. If the solubility of the solid phase in the liquid is greater than that of the liquid in the solid, volume expansion can occur.

This happens because the liquid may infiltrate grain boundaries, leaving behind larger voids, causing overall expansion. For example, in Fe-Cu alloy transient liquid phase sintering, inverse densification can result from such solubility mismatches.

3. Phase Transformations Causing Volume Changes

Certain crystal structures undergo phase transformations at high temperatures, leading to volume expansion. For instance, some high-temperature superconducting ceramics change their crystal structure from near cylindrical to flaky forms during sintering, resulting in volume expansion of up to 35%. These volume changes can compromise the original dense structure, causing cracking and hindering further densification.

4. Unequal Atomic Diffusion

In metal and ceramic powders, non-uniform atomic, ionic, or vacancy diffusion can also cause inverse densification. As early as the 1950s, scientists observed that in Cu-Ni and Cu-Ag alloys during sintering, “necking grooves” or depressions form at grain boundaries, hindering their growth. This is often due to differences in diffusion rates of the alloying elements, especially when low-melting-point metals diffuse faster, causing vacancies to migrate unevenly. Similarly, in ceramics like MgO and Al₂O₃, migration of cations such as Mg²⁺, Al³⁺, and Si⁴⁺ can lead to analogous effects.

Conclusion

Although inverse densification may seem counterintuitive, it results from the complex interplay of multiple mechanisms. Understanding these processes helps us better control sintering techniques and design new materials while avoiding or harnessing these phenomena.

The field of materials science is rich and fascinating, with many “anomalous” phenomena hiding deep physical and chemical insights. I hope this overview enhances your understanding of inverse densification during sintering!

For top-quality ceramic products, Advanced Ceramics Hub provides tailored solutions and precision machining techniques for various applications.

Looking for technical ceramic products? Contact us today!