Piezoelectric Materials for Advanced Thermal Management

In the rapidly evolving landscape of modern technology, thermal management has emerged as a critical challenge across various industries, including electronics, aerospace, automotive, and energy systems. As devices become smaller, more powerful, and densely packed, they generate excessive heat that can lead to reduced performance, shortened lifespan, and even catastrophic failures. Traditional cooling methods, such as fans, heat sinks, and liquid cooling systems, often fall short in terms of efficiency, size constraints, noise levels, and energy consumption. This is where innovative materials like piezoelectric substances come into play, offering a promising avenue for advanced thermal management solutions.

Piezoelectric materials are unique in their ability to convert mechanical stress into electrical energy (direct piezoelectric effect) and vice versa (inverse piezoelectric effect). This bidirectional energy conversion makes them versatile for applications beyond sensors and actuators, extending into thermal regulation. For instance, by leveraging the inverse piezoelectric effect, these materials can generate mechanical vibrations or deformations that facilitate airflow or fluid movement, effectively dissipating heat without the need for bulky mechanical components. Additionally, some piezoelectric materials exhibit pyroelectric properties, where temperature changes induce electrical charges, enabling passive thermal sensing and energy harvesting to power cooling mechanisms.

The exploration of piezoelectric materials for thermal management is particularly timely, given the growing emphasis on sustainable and energy-efficient technologies. By integrating piezoelectric elements, systems can achieve active cooling with minimal power input, reduced noise, and enhanced reliability. This article delves into the fundamentals, applications, challenges, and prospects of these materials, highlighting their potential to revolutionize thermal management strategies.

At Advanced Ceramics Hub, we specialize in high-quality piezoelectric ceramic products with a variety of forms and specifications, ensuring optimal performance for industrial and scientific applications.

What Are Piezoelectric Materials?

In simple terms, piezoelectric materials are substances that generate an electric charge in response to applied mechanical stress (pressure) and, conversely, change shape slightly when an electric field is applied.

The word itself comes from the Greek piezein, which means “to squeeze or press.”

How Do They Work? (The Simplified Science)

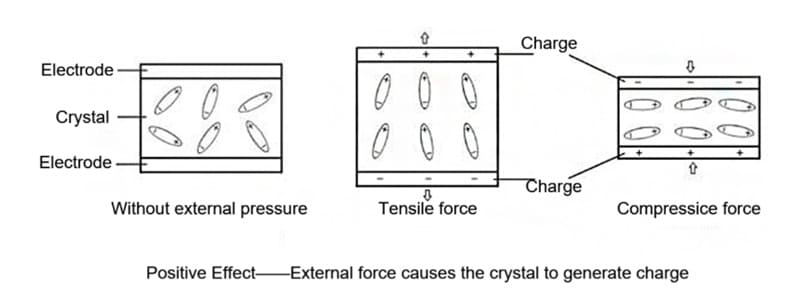

The magic happens because of the material’s unique crystal structure.

- Natural Asymmetry: At the atomic level, these materials have a crystalline structure where the positive and negative charges (ions) are not perfectly symmetrical. Think of it like a bunch of tiny magnets arranged so that their positive and negative ends don’t quite cancel each other out.

- The Squeeze Effect (Mechanical → Electrical):

- When you apply pressure (such as squeezing, bending, or vibrating) to the material, you deform its crystal structure.

- This deformation forces the positive and negative charges to shift, creating a small imbalance.

- This imbalance results in an electrical potential difference (voltage) across the material. This is called the direct piezoelectric effect.

- The Electric Effect (Electrical → Mechanical):

- When you apply an electric voltage to the material, the charged ions within the crystal are attracted or repelled by the external field.

- This causes the entire crystal structure to deform—it expands, contracts, or bends very slightly. This is called the converse (or inverse) piezoelectric effect.

This two-way relationship is the fundamental principle behind all piezoelectric applications.

Common Piezoelectric Materials

These materials can be naturally occurring crystals, manufactured ceramics, or even polymers.

- Single-Crystal Piezoelectric Materials: Represented by quartz (crystal), these materials exhibit high mechanical strength and stability but come at a higher cost, making them suitable for precision instruments.

- Ceramic Piezoelectric Materials: Represented by barium titanate (BaTiO₃) and lead zirconate titanate (PZT), these materials have a high electromechanical coupling coefficient and are easy to process, but have a large temperature coefficient.

- Thin-Film Piezoelectric Materials: Materials such as zinc oxide (ZnO) and polyvinylidene fluoride (PVDF) are flexible with low piezoelectric coefficients, making them suitable for underwater acoustic transducers.

- Polymeric Piezoelectric Materials: This category includes both natural polymers (such as bone and DNA) and synthetic polymers (like PVDF). They are characterized by flexibility and low density but typically have lower piezoelectric strain constants.

- Composite Piezoelectric Materials: These materials combine ceramics and polymers, offering both high piezoelectric performance and toughness. An example is piezoelectric ceramic-resin matrix composites.

| Material | Piezoelectric Coefficient (pC/N) | Curie Temperature (°C) | Key Advantages | Limitations |

| Quartz | ~2-3 | 573 | High stability, low cost | Low strain output |

| PZT | >300 | 200-400 | High electromechanical coupling | Lead toxicity, temperature sensitivity |

| PVDF | 20-30 | ~100 | Flexible, biocompatible | Poor thermal stability, low efficiency |

Applications of Piezoelectric Materials in Thermal Management

This is a highly specialized and cutting-edge topic. The application of piezoelectric materials in thermal management is an ingenious and efficient field. It primarily leverages the material’s ability to convert mechanical energy to actively drive fluid flow or generate other cooling effects, rather than functioning as a conventional heat-generating or conductive element.

In thermal management, piezoelectric materials are not used as traditional passive heat sinks (like copper or aluminum). Instead, they act as the “heart” or “engine” of miniature active cooling systems, converting electrical energy into mechanical motion to enhance heat dissipation.

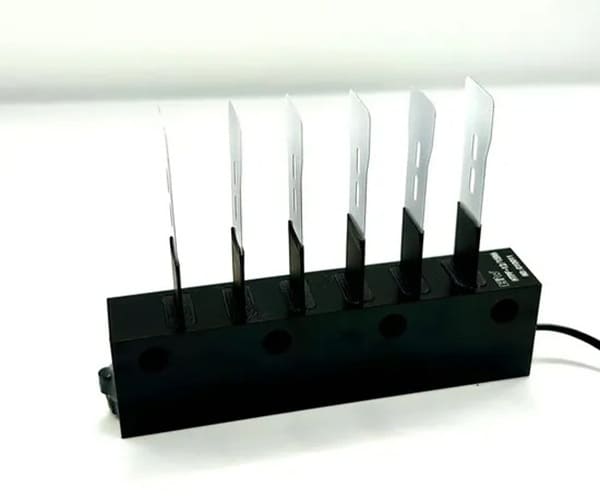

1. Piezoelectric Fans / Synthetic Jets

A piezoelectric fan is a brushless fan that utilizes the inverse piezoelectric effect of piezoelectric materials (such as PZT ceramics) to convert electrical energy into mechanical vibration, thereby driving the fan blades to oscillate and generate airflow. It is the most mature and commonly used application.

Working Principle:

- Inverse Piezoelectric Effect: An alternating voltage is applied to a piezoelectric ceramic patch (typically PZT), causing it to vibrate with a high-frequency bending motion.

- Actuating a Blade: The patch is often bonded to a flexible thin plate (called a blade or cantilever). The vibration of the patch causes the blade to oscillate rapidly at high speeds (frequencies can reach tens to hundreds of Hz).

- Agitating Air: The blade’s movement disrupts the stagnant “boundary layer” of air on a device’s surface (the region with the highest thermal resistance). It “pushes” hot air away and draws in cooler ambient air, significantly enhancing convective heat transfer.

Application Scenarios:

- Laptops and Servers: Cooling CPUs, GPUs, and other heat-generating components, especially in extremely space-constrained areas. Compared to traditional fans, they are thinner, more energy-efficient, and silent (or operate at inaudible frequencies).

- LED Lighting: Effectively cools LED chips, significantly extending their lifespan and maintaining light output efficiency.

- Aerospace Electronics: Provides reliable cooling in sealed enclosures where traditional fans cannot be used.

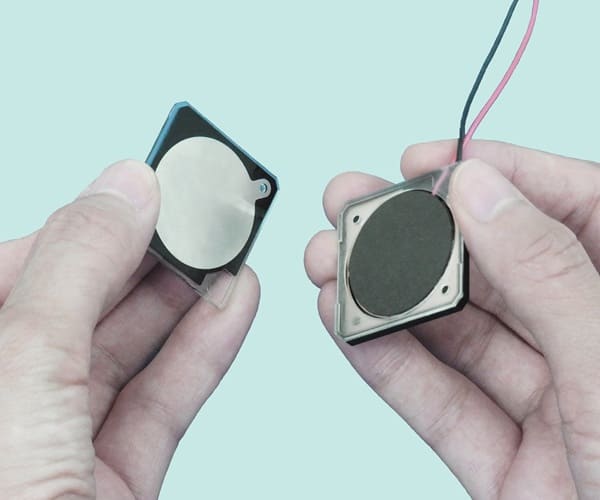

2. Piezoelectric Pumps

A piezoelectric micropump is a novel type of fluid driver. It does not require an additional drive motor but instead utilizes the inverse piezoelectric effect of piezoelectric ceramics to deform a piezoelectric actuator. This deformation causes volume changes in the pump chamber to achieve fluid output or uses the actuator’s vibration to transport liquid.

Working Principle:

- A piezoelectric element is integrated into a diaphragm within a pump chamber.

- Applying a voltage causes the element to deform, cyclically changing the volume of the pump chamber (expanding and contracting).

- Combined with inlet and outlet check valves (or a valveless design), this volume change creates a directional flow of liquid.

Application Scenarios:

- Microchannel Liquid Cooling Systems: Provides active, highly efficient cooling for components with high heat flux densities, such as high-performance CPUs/GPUs, laser diodes, and radar T/R modules. Piezoelectric pumps are ideally suited for these miniaturized, integrated systems.

- Drug Delivery, Lab-on-a-Chip: While not strictly thermal management, the principle is identical, demonstrating precise micro-scale fluid control.

3. Ultrasonic De-icing / Anti-icing

This is a specialized form of thermal management that maintains a system’s thermal performance by preventing ice accumulation.

Working Principle:

- Piezoelectric patches are bonded to surfaces requiring ice protection (e.g., aircraft wings, wind turbine blade leading edges).

- A high-frequency voltage is applied, exciting the patches to produce intense ultrasonic vibrations.

- These vibrations generate high shear stresses at the interface between the ice and the material surface, breaking the ice’s adhesion and causing it to crack and detach.

Advantage:

- Extremely low energy consumption compared to traditional electro-thermal de-icing, as it does not require heating the entire surface.

4. Energy-Harvesting for Thermal Management

This is a more indirect but promising approach.

Working Principle:

- Direct Piezoelectric Effect: Harvest energy from the device’s own vibrations or thermal expansion/contraction stresses to generate electricity.

- Powering Systems: This harvested micro-energy is used to power a small active cooling system (like a micro-fan or pump mentioned above).

Vision:

- To create a self-powered, self-regulating, smart thermal management closed-loop system, particularly for devices like IoT sensors, where battery replacement is difficult.

Explore our optimized piezoelectric ceramic products.

Advantages and Challenges of Piezoelectric Materials in Thermal Management

Piezoelectric materials offer a unique paradigm for thermal management, moving from passive conduction to active, mechanical agitation. Their value proposition is defined by a set of compelling advantages alongside distinct technological challenges.

Advantages:

- Miniaturization and Integration: Ideal for microelectronics and MEMS (Micro-Electro-Mechanical Systems) applications.

- High Efficiency and Low Energy Consumption: High energy conversion efficiency with low power draw.

- Rapid Response: High vibration frequency allows for very quick start-up, shutdown, and control.

- Silent Operation: Operating frequencies are often beyond the range of human hearing.

- No Electromagnetic Interference (EMI): Unlike electromagnetic motors, they do not generate additional EMI.

- High Reliability: No moving parts like bearings, leading to a long lifespan.

Challenges:

- Limited Force and Displacement: The output force and deformation of a single piezoelectric element are small, often requiring arrays or mechanical amplification structures.

- Cost: Materials and processing costs for high-performance piezoceramics (like PZT) can be higher than for traditional fans.

- System Design Complexity: Requires supporting drive circuitry and control systems.

- Temperature Limits: Piezoelectric materials have a Curie temperature; exceeding this point causes them to lose their piezoelectric properties.

Request a custom quote for high-quality piezoelectric ceramic materials.

Future Directions and Innovations of Piezoelectric Materials in Thermal Management

The evolution of this field is focused on overcoming current limitations and unlocking new functionalities. Research is pushing towards multifunctional integration, material science breakthroughs, and AI-driven smart systems.

1. Material Science and Composition Innovation

The core of future advancement lies in developing new, superior piezoelectric materials.

Lead-Free Piezoceramics: A major drive is to replace lead-based materials like PZT due to environmental and regulatory (RoHS) concerns. Research into high-performance alternatives like:

- Sodium Potassium Niobate (KNN): Offers good piezoelectric properties and a high Curie temperature.

- Bismuth Sodium Titanate (BNT): Another promising lead-free candidate.

- Future Goal: Achieving the performance and stability of PZT without the toxicity, making the technology more sustainable and marketable.

Composite Materials: Developing advanced composites that combine the best properties of different materials.

- Polymer-Ceramic Composites: Embedding piezoelectric ceramic particles (e.g., PZT) into a flexible polymer matrix (e.g., PDMS). This increases fracture resistance (reducing brittleness) while maintaining decent piezoelectric performance, enabling flexible and conformal cooling patches.

- Graphene-Enhanced Composites: Incorporating graphene or carbon nanotubes can improve both the mechanical strength and the thermal conductivity of the piezoelectric element itself, allowing it to act as both an actuator and a minor heat spreader.

High-Temperature Materials: Developing materials with a significantly higher Curie Temperature for use in extreme environments like jet engine electronics, automotive power electronics, and deep-well drilling equipment.

2. Multifunctional and Structural Systems

Moving from discrete “add-on” coolers to seamlessly integrated solutions.

✅Embedded and Additively Manufactured Actuators: Instead of attaching a piezoelectric patch, future devices could have actuators 3D-printed or embedded directly into the structure of a heat sink or device housing. This would create a truly monolithic, self-cooling structure with optimized fluid dynamics.

✅Energy Harvesting Integration (Self-Powered Cooling): Creating closed-loop systems where the piezoelectric material serves a dual purpose:

- Harvester: It uses waste vibration from the environment (e.g., an engine, a spinning hard drive, or even user interaction) to generate electricity.

- Actuator: That harvested energy powers its cooling function. This is a “set-and-forget” solution ideal for wireless sensor nodes and IoT devices in remote locations.

✅Hybrid and Multi-Scale Systems: Integrating piezoelectric actuators with other advanced cooling technologies:

- Piezo + Electrohydrodynamic (EHD): Using piezoelectric vibrations to enhance the efficiency of EHD ion-driven airflow.

- Piezo + Microchannels: Using ultra-precise piezoelectric pumps to drive single-phase or two-phase liquid cooling through complex, miniaturized channel networks for high-heat-flux chips.

3. Advancements in Actuation Design and Amplification

Overcoming the fundamental challenge of limited stroke through smarter engineering.

- Bio-Inspired Designs: Mimicking nature to create more efficient actuators. For example, designing piezoelectric fan arrays that mimic the flapping motion of insect wings or bird feathers to achieve greater thrust and efficiency with less energy.

- Advanced Amplification Mechanisms: Moving beyond simple cantilevers to more sophisticated mechanical structures like cymbal-type actuators, bridge-lever mechanisms, or flextensional designs that can convert small piezoelectric strains into much larger displacements.

- MEMS Integration: The full miniaturization of piezoelectric pumps and fans using Micro-Electro-Mechanical Systems (MEMS) fabrication techniques. This would allow for the placement of hundreds of microscopic cooling actuators directly onto a chip package, enabling hyper-localized hotspot cooling.

4. Intelligence and Predictive Control

The integration of IoT and AI will transform piezoelectric cooling from a static function into a dynamic, predictive system.

- AI-Optimized Control: Using machine learning algorithms to analyze historical and real-time thermal data. The system can predict thermal loads (e.g., anticipating a CPU spike from a launched application) and preemptively activate or modulate the piezoelectric coolers for maximum efficiency and minimal power use.

- Distributed Sensor-Actuator Networks: Creating a network of numerous small piezoelectric elements that can both sense local temperature (using the direct piezoelectric effect or as a resistive sensor) and actuate cooling (using the inverse effect). This allows for real-time, closed-loop cooling of specific hotspots across an entire chip surface.

In the field of thermal management, the value of piezoelectric materials lies not in their ability to dissipate heat themselves, but in their capacity to efficiently convert electrical energy into precise, controllable mechanical motion. This makes them ideal actuator components for active enhanced cooling systems. They provide compact, quiet, and highly efficient solutions to the increasingly critical challenge of thermal management in electronics (especially in space-constrained, high heat-flux scenarios), representing a vital direction for the future of advanced cooling technology.

For top-quality ceramic products, Advanced Ceramics Hub provides tailored solutions and precision machining techniques for various applications.

Looking for premium piezoelectric ceramic products? Contact us today!