High-Performance Ceramic Substrates: Characteristics and Processes

Ceramic substrates play a crucial role in modern high-performance engineering. They not only serve as supporting and insulating materials in electronic devices but are also widely used in aerospace, automotive industries, and energy technologies due to their superior thermal stability, mechanical strength, and electrical properties. The primary functions of ceramic substrates are to provide electrical insulation, heat dissipation, and structural support, ensuring the stability and reliability of electronic components and systems under extreme conditions.

At Advanced Ceramics Hub, we specialize in high-quality ceramic substrates with a variety of forms and specifications, ensuring optimal performance for industrial and scientific applications.

The Definition of Ceramic Substrates

Ceramic Substrates are specialized materials used as a base or supporting layer in electronic, mechanical, and thermal applications due to their excellent electrical insulation, thermal conductivity, and mechanical stability. They are typically made from inorganic, non-metallic compounds (such as alumina, aluminum nitride, or beryllia) that are sintered at high temperatures to form a rigid, durable structure.

Key Characteristics of Ceramic Substrates:

- High Thermal Conductivity – Efficiently dissipates heat in high-power applications.

- Electrical Insulation – Prevents current leakage in electronic circuits.

- Mechanical Strength – Resists cracking and deformation under stress.

- Chemical Stability – Resistant to corrosion and oxidation.

- Low Thermal Expansion – Maintains dimensional stability under temperature fluctuations.

Looking for top-quality ceramic substrate products? Explore the Advanced Ceramics Hub’s selection.

Material Selection for High-Performance Ceramic Substrates

Choosing the right ceramic substrate material depends on thermal, electrical, mechanical, and cost requirements. Below is a comparative analysis of key ceramic substrate materials for high-performance applications:

When selecting materials, several key factors need to be considered:

- Thermal Stability: The thermal expansion coefficient, thermal conductivity, and high-temperature stability of ceramic materials are important considerations. Ceramics with high thermal stability can withstand high-speed operation and high-temperature environments without losing their performance.

- Mechanical Strength: Ceramic substrates must maintain stable performance under mechanical stress or impact. This requires the selection of ceramics with high strength, hardness, and wear resistance.

- Electrical Properties: For ceramic substrates used in electronic applications, electrical insulation is critical. The material’s resistance, dielectric constant, and conductivity directly affect its performance.

Common High-performance Ceramic Substrate Materials

| Material Type | Characteristics | Main Applications |

| Alumina (Al2O3) | Excellent thermal stability and electrical insulation | Electronic packaging, sensors |

| Aluminum Nitride (AlN) | High thermal conductivity and heat resistance | High-power electronic devices, heat exchangers |

| Zirconia (ZrO2) | Superior wear resistance and toughness | Aerospace, engine components |

| Silicon Nitride (Si3N4) | High strength and high heat resistance | High-temperature applications, mechanical components |

| Beryllium Oxide (BeO) | High thermal conductivity and electrical insulation, toxic | High-performance electronic components, heat sinks |

Comparison of High-Performance Ceramic Substrate Materials

| Property | Alumina (Al₂O₃) | Aluminum Nitride (AlN) | Beryllium Oxide (BeO) | Silicon Nitride (Si₃N₄) | Zirconia (ZrO₂) |

| Thermal Conductivity (W/m·K) | 20-30 | 150-220 | 250-330 | 15-30 | 2-3 |

| Dielectric Strength (kV/mm) | 10-15 | 15-20 | 12-15 | 15-25 | 8-12 |

| CTE (ppm/°C) | 7-8 | 4.5 | 6-8 | 3.2-3.5 | 10-11 |

| Electrical Resistivity (Ω·cm) | >10¹⁴ | >10¹⁴ | >10¹⁴ | >10¹⁴ | >10¹⁰ |

| Max Operating Temp. (°C) | ~1600 | ~1800 | ~2000 | ~1400 (long-term) | ~2400 |

| Mechanical Strength | Moderate | Good | Good | Excellent | Exceptional |

| Fracture Toughness (MPa·m¹/²) | 3-4 | 2-3 | 2-3 | 6-7 | 5-12 |

| Cost | Low | High | Very High | Very High | High |

| Toxicity | Non-toxic | Non-toxic | Toxic | Non-toxic | Non-toxic |

| Key Advantages | Cost-effective, widely available | High thermal conductivity, low CTE | Best thermal conductivity | Outstanding mechanical properties, thermal shock resistant | High fracture toughness, biocompatible |

| Limitations | Moderate thermal performance | Expensive, processing sensitive | Toxic, restricted use | Expensive, lower thermal conductivity than AlN/BeO | Low thermal conductivity |

| Primary Applications | PCBs, LEDs, consumer electronics | High-power electronics, RF modules | Military/aerospace RF | Bearings, cutting tools, engine components | Medical implants, sensors |

Explore our optimized ceramic substrate products.

Ceramic Substrate Types by Manufacturing Process

Ceramic substrates are critical components in advanced electronics, offering superior thermal management, electrical insulation, and mechanical stability. Their performance heavily depends on the manufacturing process used. Next, we will explore the four key fabrication technologies—LTCC, HTCC, DBC, and DPC—highlighting their unique processes, material properties, and ideal applications. Whether for high-power modules, RF systems, or precision microelectronics, understanding these methods ensures optimal substrate selection for your technical requirements.

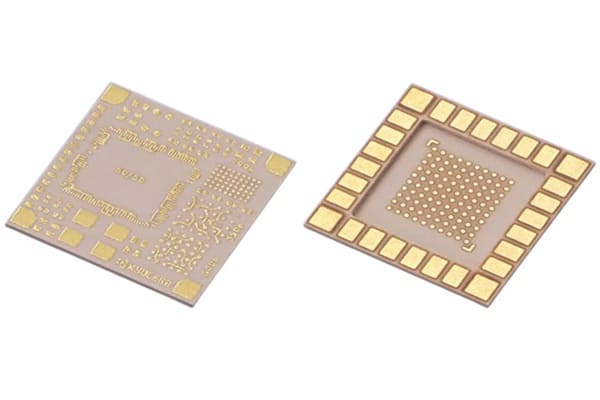

1. LTCC (Low-Temperature Co-fired Ceramic)

✅Process Characteristics:

- Temperature Range: 850–900°C

- Materials: Glass-ceramic composites (e.g., Al₂O₃ + SiO₂/B₂O₃ glass)

- Conductors: Screen-printed Ag/Au/Cu pastes

✅Key Features:

- Multi-layer 3D structures with embedded passives (resistors/capacitors)

- Low dielectric loss at high frequencies

✅Primary Applications:

▶ RF/wireless communication modules (5G, antennas)

▶ MEMS and sensor packaging

▶ Automotive radar systems

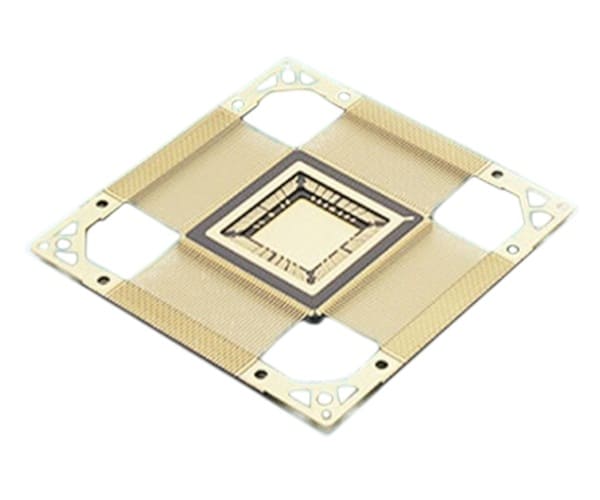

2. HTCC (High-Temperature Co-fired Ceramic)

✅Process Characteristics

- Temperature Range: 1600–1800°C

- Materials: Pure Al₂O₃/AlN without glass additives

- Conductors: Tungsten (W) or Molybdenum (Mo) metallization

✅Key Features:

- Superior mechanical strength and thermal shock resistance

- Hermetic sealing capability for harsh environments

✅Primary Applications:

▶ Aerospace engine sensors

▶ High-brightness LED packages

▶ Nuclear reactor monitoring systems

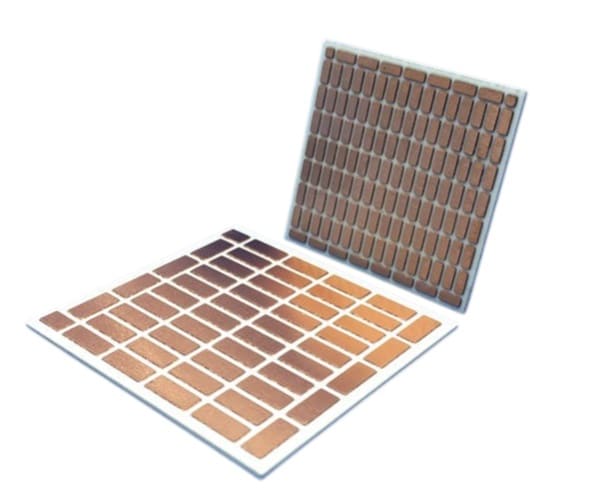

3. DBC (Direct Bonded Copper)

✅Process Characteristics

- Bonding Method: Eutectic bonding at 1065–1083°C (Cu-Al₂O₃ reaction)

- Structure: 100–300μm Cu foil bonded to ceramic (Al₂O₃/AlN)

✅Key Features:

- Ultra-high thermal conductivity (AlN DBC: >170 W/m·K)

- High current-carrying capacity (thick Cu layers)

✅Primary Applications:

▶ EV power modules (IGBTs, SiC inverters)

▶ High-power LED arrays

▶ Industrial motor drives

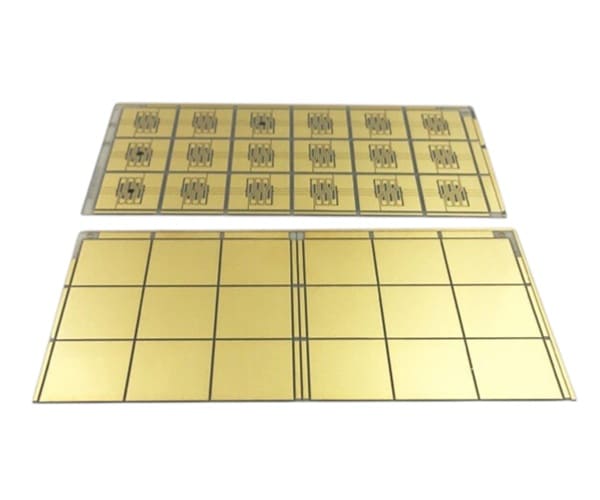

4. DPC (Direct Plated Copper)

✅Process Characteristics

- Fabrication: Thin-film process (sputtering + electroplating)

- Structure: 10–50μm patterned Cu on ceramic (Al₂O₃/AlN)

✅Key Features:

- Sub-50μm line resolution (photolithography compatible)

- Low interfacial thermal resistance (<0.1 K·mm²/W)

✅Primary Applications:

▶ Laser diode/LD packaging

▶ High-density IC substrates

▶ Precision medical imaging sensors

Comparative Summary

| Technology | Resolution | Thermal Performance | Cost | Best Use Case |

| LTCC | ~100μm | Poor (2–5 W/m·K) | Low | RF multi-layer modules |

| HTCC | ~150μm | Moderate (20–30 W/m·K) | Very High | Extreme environments |

| DBC | >200μm | Excellent (170+ W/m·K) | Medium | High-power electronics |

| DPC | <50μm | Good (150+ W/m·K) | High | Precision microelectronics |

Request a custom quote for high-quality ceramic substrate products.

FAQ

| Question | Answer |

| What are the key properties of ceramic substrates? | Ceramic substrates offer excellent thermal stability, mechanical strength, and electrical insulation. |

| How does thermal stability affect ceramic materials? | Thermal stability allows ceramics to withstand high temperatures and extreme conditions without losing performance. |

| What is the importance of mechanical strength in ceramics? | High mechanical strength ensures that ceramic substrates can handle pressure and impact without compromising stability. |

| Why is electrical insulation critical for ceramic substrates? | Electrical insulation prevents short circuits and ensures safe and efficient operation in electronic applications. |

| What applications are aluminum nitride (AlN) used in? | AlN is used in high-power electronic devices and heat exchangers due to its excellent thermal conductivity. |

| What makes beryllium oxide (BeO) ideal for high-performance electronics? | BeO’s high thermal conductivity and electrical insulation make it ideal for heat sinks and high-performance electronic components. |

At Advanced Ceramics Hub, we supply optimized-grade ceramic products that comply with ASTM, ISO, and AMS standards, ensuring outstanding quality and reliability.

As modern electronics push the boundaries of power, frequency, and miniaturization, ceramic substrates have emerged as indispensable enablers across industries. This analysis of LTCC, HTCC, DBC, and DPC technologies highlights how material properties and manufacturing processes dictate their specialized roles—from 5G modules to EV power trains.

As the backbone of tomorrow’s electronics, ceramic substrates will continue evolving, driven by demands for higher efficiency, smaller form factors, and extreme-environment reliability. Their future lies not just in incremental improvements, but in reimagining how ceramics integrate with next-generation semiconductor and quantum technologies.

For top-quality ceramic products, Advanced Ceramics Hub provides tailored solutions and precision machining techniques for various applications.

Looking for premium ceramic substrate products? Contact us today!