Decoding the 5 Key Microstructures of Alumina Powder: From Morphology to Cutting-Edge Applications

Alumina powder, also known as aluminum oxide (Al2O3), is a versatile material widely recognized for its exceptional physicochemical properties, including high hardness, thermal stability, and chemical inertness. The microstructure—or morphology—of alumina powder plays a pivotal role in determining its performance across various applications. Factors such as particle shape, size distribution, surface area, and defects collectively influence properties like flowability, sinterability, and thermal conductivity. As industries evolve, alumina powder’s role has expanded from traditional ceramics to cutting-edge fields like electronics, energy storage, and biomedicine.

In recent years, advancements in synthesis techniques, such as spray drying and sol-gel methods, have enabled precise control over these microstructures, leading to tailored materials for specific needs. By 2025, the global alumina powder market is projected to grow significantly, driven by demand in electric vehicles (EVs), renewable energy, and additive manufacturing. This article delves into five key microstructures: flake-shaped, spherical, hollow spherical, needle/fibrous, and rhombic alumina powders. We will explore their structural features, advantages, applications, and emerging trends, providing a comprehensive guide for researchers and industry professionals.

At Advanced Ceramics Hub, we specialize in high-quality alumina powder products with various specifications, ensuring optimal performance for industrial and scientific applications.

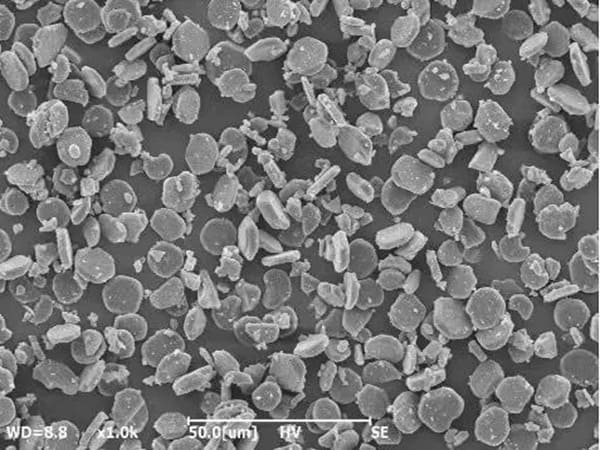

Flake-Shaped Alumina Powder

Flake-shaped alumina powder features a unique two-dimensional planar structure, resembling thin platelets with high aspect ratios. This morphology results from processes like mechanical milling or chemical vapor deposition, yielding particles with small sizes (often below 10 μm) and excellent dispersibility. The flat surfaces promote strong interfacial interactions, making it ideal for applications requiring barrier properties or enhanced reflectivity.

Key Characteristics and Properties

- High Aspect Ratio: The flakes are very thin compared to their width (high diameter-to-thickness ratio). This is the most critical characteristic.

- Excellent Barrier Properties: The flakes align parallel to a surface, creating a labyrinth effect that significantly lengthens the diffusion path for gases, liquids, and corrosive elements. This provides outstanding shielding and anti-corrosion performance.

- Reinforcement: In composites and coatings, the flakes act as a reinforcing agent, improving mechanical properties like hardness, scratch resistance, and stiffness.

- Thermal Stability: Like all alumina, it has a very high melting point and excellent thermal stability, making it suitable for high-temperature applications.

- Electrical Insulation: It is an excellent electrical insulator.

- Chemical Inertness: It is highly resistant to attack by solvents, acids, and alkalis.

- UV Reflectivity: Certain grades can provide good reflectivity and UV resistance.

- Smooth Surface: Contributes to high gloss and smoothness in coatings.

Performance Advantages of Flake-Shaped Alumina

- Superior Adhesion: Large surface contact area enhances bonding capabilities.

- Significant Shielding Effects: Provides effective protection against UV radiation and corrosion.

- Excellent Chemical Resistance: Resists acids and alkalis effectively.

- High-Temperature Resistance: Maintains stability and performance at temperatures up to 2000°C.

- Mechanical Wear Resistance: Withstands abrasion and wear, enhancing durability.

- High Thermal Conductivity: Superior thermal conductivity compared to polymers.

- Electrical Resistivity: Acts as a preferred filler in composite materials.

- Reduced Dielectric Loss: Surface-modified flake alumina decreases dielectric loss in high-frequency substrates.

- Enhanced Signal Integrity: Improves performance in electronic applications through better signal integrity.

Applications of Flake-Shaped Alumina

✅Pigments and Coatings

- Metallic finishes in automotive paints

- Corrosion protection layers

✅Cosmetics

- Pearlescent effects

✅Inks

- Reflectivity enhancement

✅Abrasives

- Polishing applications

✅Polymer Fillers

- Boosting thermal conductivity in electronics

- Forming networks for heat dissipation

✅Ceramics

- Toughening agent to increase fracture toughness

✅Emerging Uses

- Catalyzing hydrogen production in fuel cells

- Bioinspired materials mimicking butterfly wings for light absorption

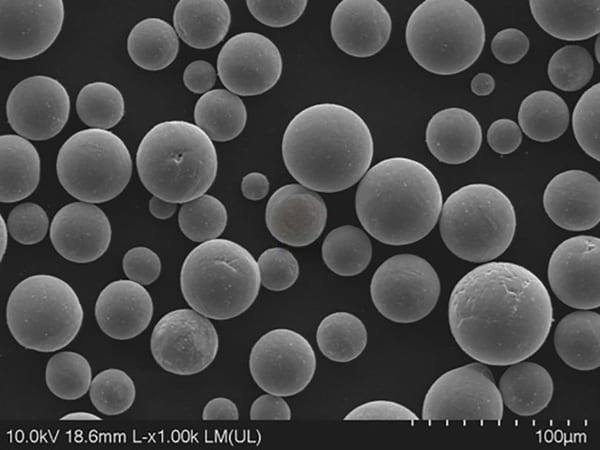

Spherical Alumina Powder

Spherical alumina powder is characterized by its uniform, round particles, which offer superior flowability and packing density compared to irregular shapes. Produced via methods like plasma spheroidization or atomization, these particles typically range from 1-50 μm, ensuring consistent behavior in processing.

Key Properties and Characteristics

The spherical shape imparts several superior properties:

- High Sphericity & Smooth Surface: Low internal friction and excellent flowability.

- High Purity: Typically >99.99% Al₂O₃, minimizing impurities that can affect performance.

- High Packing Density: Spheres pack together more efficiently than irregular shapes, leading to higher density in composites and formulations.

- Excellent Thermal Conductivity: Efficiently transfers heat, which is crucial for thermal management applications.

- High Electrical Insulation: Maintains its insulating properties even at high temperatures.

- Good Chemical Inertness: Resistant to corrosion by acids, alkalis, and other harsh chemicals.

- High Mechanical Strength: Provides structural reinforcement in composites.

- Controlled Particle Size Distribution: Available in precise size ranges, from nanometers to over 100 microns.

Its advantages include excellent press-forming and sintering characteristics, leading to dense, high-quality ceramics with minimal defects. The spherical shape minimizes agglomeration, enhances dispersibility, and improves thermal conductivity, making it suitable for heat dissipation applications.

The Applications of Spherical Alumina Powder

- Catalysts: Porous supports with uniform loading.

- Ceramic Manufacturing: Components such as insulators and substrates.

- Electronics: Thermal interface materials (TIMs) for LEDs and electric vehicles (EVs), and improving heat transfer in battery systems.

- Additive Manufacturing (AM): Enhanced flowability (20-30% better compared to non-spherical powders).

Recent 2025 trends highlight its role in EV battery coatings and biomedical implants, where biocompatibility aids wear resistance.

Hollow Spherical Alumina Powder

Hollow spherical alumina powder features spherical particles with internal cavities, resulting in high specific surface areas (often >50 m²/g) and low density. Synthesized primarily through spray drying, where slurry droplets form shells via rapid evaporation, this morphology creates porous structures ideal for adsorption.

Key Properties and Characteristics

The hollow structure defines its core characteristics:

- Low Density & Very Low Weight: This is its most defining property. The hollow core drastically reduces the particle’s density compared to its solid counterparts.

- High Specific Surface Area: The interior surface of the hollow sphere adds to the total surface area, which can be beneficial for catalysis or adsorption.

- Low Thermal Conductivity: The trapped air or gas within the hollow sphere acts as an excellent insulator. This is the opposite of solid spherical alumina, which is prized for high thermal conductivity.

- High Flowability: Like solid spheres, the spherical shape ensures excellent flow characteristics.

- Good Chemical and Thermal Stability: It retains alumina’s inherent inertness and ability to withstand high temperatures (though the hollow structure may have a different maximum service temperature than solid alumina).

- Dielectric Properties: It is an excellent electrical insulator.

Advantages include large surface area for catalysis, thermal insulation due to trapped air, and ease of handling in macro-spheres for filtration. The preparation process involves high-temperature drying, leading to varied cavity sizes based on pressure dynamics.

Primary Applications of Hollow Spherical Alumina Powder

The applications for hollow spheres are niche but critical, leveraging their unique lightweight and insulating properties.

A. Lightweight Thermal Barrier Coatings (TBCs)

This is a premier application. The powder is used in:

- Plasma Spray Coatings: Hollow spheres are fed into a plasma plume, where they melt on the outside but can remain semi-molten or retain their structure, creating a highly porous, layered coating when they impact the substrate.

- Use Case: Coating gas turbine blades, engine components, and other high-temperature parts in aerospace and power generation. The coating provides exceptional thermal insulation, protecting the underlying metal from extreme heat, while also adding minimal weight.

B. Lightweight, High-Temperature Composites

Used as a functional filler in polymers, metals, and ceramics to create composites that are:

- Extremely Lightweight: Crucial for aerospace and automotive applications where weight reduction is paramount.

- Thermally Insulative: For components that need to withstand heat without transferring it.

- Low Dielectric Constant: Useful in radomes and electromagnetic wave-transparent materials.

C. Catalysis and Catalyst Supports

The high specific surface area and permeability make them excellent supports for catalytically active phases. Reactants can diffuse through the porous shell, react on the interior surface, and products can diffuse out, increasing overall catalytic efficiency.

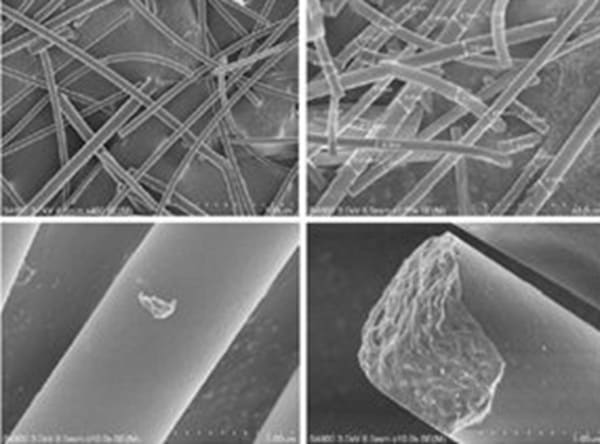

Needle or Fibrous Alumina Powder

Needle or fibrous alumina powder consists of elongated, whisker-like structures, often α-Al2O3 crystals with high aspect ratios (length-to-diameter >10). Produced via sol-gel or electrospinning, these fibers exhibit diameters of 10-100 nm and lengths up to 100 μm.

Key advantages of Needle/Fibrous Alumina Powder

- High Aspect Ratio

- Superior high-temperature resistance (>1800°C)

- Oxidation resistance

- High modulus (up to 400 GPa)

- Exceptional Mechanical Strength and Stiffness

Primary Applications of Needle/Fibrous Alumina Powder

The applications leverage the incredible reinforcing power of these fibers, often in extreme environments.

A. Reinforcing Agent in Composites

This is the primary application. They are added to matrices to dramatically improve mechanical properties:

- Metal Matrix Composites (MMCs): Added to aluminum, magnesium, or other metals to create ultra-strong, lightweight, and heat-resistant materials for aerospace (e.g., turbine blades, structural components), automotive (pistons, connecting rods), and military applications.

- Ceramic Matrix Composites (CMCs): Reinforcing ceramics with alumina fibers creates composites that are much tougher and more resistant to thermal shock than monolithic ceramics. Used in extreme environments like jet engine shrouds, heat shields, and brake disks.

- Polymer Matrix Composites (PMCs): Used in specialized applications where high stiffness, wear resistance, and thermal conductivity are needed, though their abrasive nature can be challenging for processing equipment.

B. Advanced Refractories and Insulation

- High-Temperature Insulation: Woven into mats or blankets for furnace linings in industries like steel and glass manufacturing. They provide excellent thermal insulation and structural integrity at temperatures exceeding 1600°C.

- Reinforcement of Refractory Castables: Adding fibrous alumina to refractory concretes improves their tensile strength and resistance to thermal shock and spalling (chipping or cracking).

C. Friction Materials

Used in brake pads and clutch facings for high-performance vehicles and industrial machinery. The high strength and thermal stability of the fibers help maintain friction properties and structural integrity at high temperatures.

D. Catalysis

Structured Catalyst Supports: Fibrous alumina can be formed into mats or felts that serve as a structured support for catalytically active phases. This geometry offers low pressure drop and high surface area, beneficial in certain reactor designs.

Rhombic Alumina Powder

Rhombic alumina powder features diamond-shaped primary crystals with a narrow particle size distribution, achieved by adding mineralizers like MgO and controlled calcination.

Advantages: high self-sharpening, grinding rate, and polishing efficiency, outperforming other shapes in abrasives.

Applications: stainless steel polishing, precision abrasives, matching international standards like Sumitomo’s AN-21. Also in electronics for substrates.

Morphology Comparison and Future Trends

Comparing these five morphologies of alumina powder highlights how the shape of the same chemical compound (Al₂O₃) dictates its properties and ultimate application.

Comparison Table of Alumina Powder Morphologies:

| Property | Flake-Shaped | Solid Spherical | Hollow Spherical | Needle/Fibrous | Rhombic (Angular) |

| Primary Function | Barrier, Oriented Reinforcement | Thermal Conduction, Flow, Packing | Thermal Insulation, Lightweighting | Mechanical Reinforcement, Toughening | Abrasion, Refractory Filler |

| Particle Morphology | Flat, plate-like particles | Perfect, smooth spheres | Cenospheres (hollow spheres) | High-aspect-ratio rods/whiskers | Sharp, angular crystals |

| Key Advantage | Creates a tortuous path for diffusion | Highest packing density & flowability | Lowest density & thermal conductivity | Highest strength & toughness | Highest hardness & abrasiveness |

| Thermal Conductivity | Medium (Anisotropic – in-plane > through-plane) | Very High (Isotropic) | Very Low (Insulating) | Medium (Isotropic in composite) | Medium |

| Packing Density | Low | Very High | Very Low | Low | Low |

| Flowability | Poor | Excellent | Good | Abrasive blasting, sandpaper, and refractories | Poor |

| Mechanical Role | Barrier Property Enhancer | Non-Reinforcing Filler | Non-Reinforcing Filler | Primary Reinforcer | Abrasive |

| Typical Applications | Anti-corrosion coatings, cosmetics | Thermal interface materials (TIMs), 3D printing | Thermal barrier coatings (TBCs), lightweight composites | Metal/Ceramic matrix composites, refractories | Abrasive blasting, sandpaper, refractories |

| Relative Cost | Medium-High | High | Very High | High | Low |

The future trends in alumina powders are driven by the demands of next-generation technologies, particularly in electronics, energy, and aerospace. The evolution is moving beyond simple morphology to intelligent, multi-functional, and application-engineered materials.

The diverse microstructures of alumina powder underscore its value in modern industries. Looking ahead, the potential in renewables and biomaterials promises further growth. Further research is encouraged, with references to ongoing studies.

For top-quality ceramic products, Advanced Ceramics Hub provides tailored solutions and precision machining techniques for various applications.

Looking for premium alumina powder products? Contact us today!