Beryllium Oxide Crucible

Beryllium Oxide Crucible

Beryllium Oxide Crucible stands out for its excellent thermal conductivity, high-temperature resistance, and chemical stability. It can endure extreme heat without deforming, making it a reliable choice for high-temperature processing and melting applications in metallurgy, nuclear technology, and advanced materials research. Its low dielectric loss and strong thermal shock resistance also support demanding thermal cycling environments. We can supply high-quality Beryllium Oxide Crucible with various specifications and competitive prices, offering customized solutions to meet specific requirements.

Or email us at sales@heegermaterials.com.Beryllium Oxide Crucible Data Sheet

| Color: | White |

| Chemical Formula: | BeO |

| Dimension: | customized |

| Shape: | Cylinder, Conical Cylinder, Rectangular, T-shape, or customized. |

| Machining Accuracy: | 0.01 mm |

| Surface Roughness: | 0.1 μm |

Beryllium Oxide Crucible Description

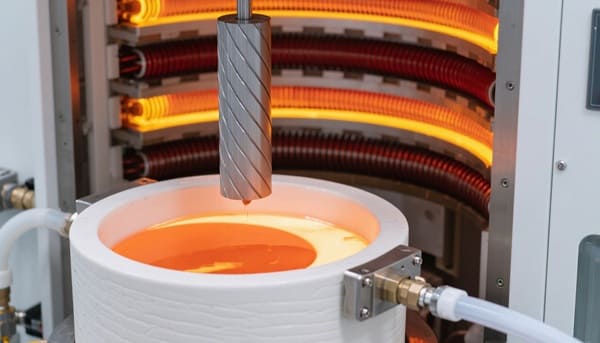

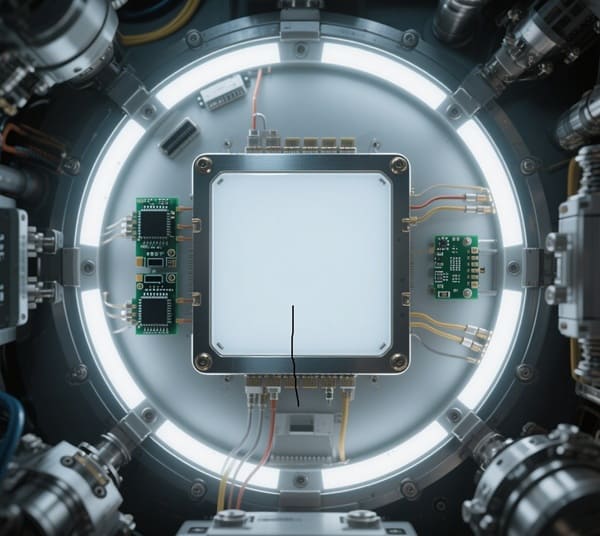

Beryllium Oxide Crucible offers exceptional performance in extreme thermal environments, combining high thermal conductivity with outstanding electrical insulation. Its low dielectric constant and ability to withstand temperatures above 2500°C make it a preferred choice for applications such as high-temperature metal processing, crystal growth, vacuum evaporation, and semiconductor production. The crucible’s chemical stability ensures minimal reaction with molten materials, while its mechanical strength helps resist thermal shock and structural degradation. Whether used in research laboratories or industrial-scale thermal systems, Beryllium Oxide Crucible delivers consistent, efficient results.

Beryllium Oxide Crucible Chemical Compositions

| Element | Content (ppm) |

|---|---|

| Boron (B) | 2 |

| Aluminum (Al) | 46 |

| Chromium (Cr) | 8 |

| Iron (Fe) | 32 |

| Magnesium (Mg) | 1000 |

| Manganese (Mn) | 2 |

| Nickel (Ni) | 9 |

| Titanium (Ti) | 5 |

| Sodium (Na) | 173 |

| Calcium (Ca) | 31 |

| Silicon (Si) | 2100 |

Beryllium Oxide Crucible Features

- High Thermal Conductivity: Efficiently transfers heat, enabling uniform temperature distribution during high-temperature processes.

- Excellent Electrical Insulation: Maintains strong dielectric properties, ensuring safe use in electrical environments.

- Superior Thermal Shock Resistance: Resists cracking and damage from rapid temperature changes, enhancing durability.

- Chemical Stability: Unaffected by corrosive molten metals and reactive gases, ensuring long service life.

- High Mechanical Strength: Withstands mechanical stress and thermal cycling without structural failure.

Beryllium Oxide Crucible Applications

- Crystal Growth: Supports uniform heating in semiconductor and optical crystal manufacturing processes.

- Metallurgical Processing: Used for melting and casting metals and alloys at very high temperatures.

- Vacuum Evaporation: Ideal for thermal evaporation in vacuum coating and thin-film deposition systems.

- Nuclear Industry: Functions in reactor environments requiring radiation resistance and thermal stability.

- Laboratory Research: Suitable for high-temperature experiments and chemical analyses due to its chemical inertness and durability.

Beryllium Oxide Ceramic Properties

Beryllium Oxide Ceramic Material Machining

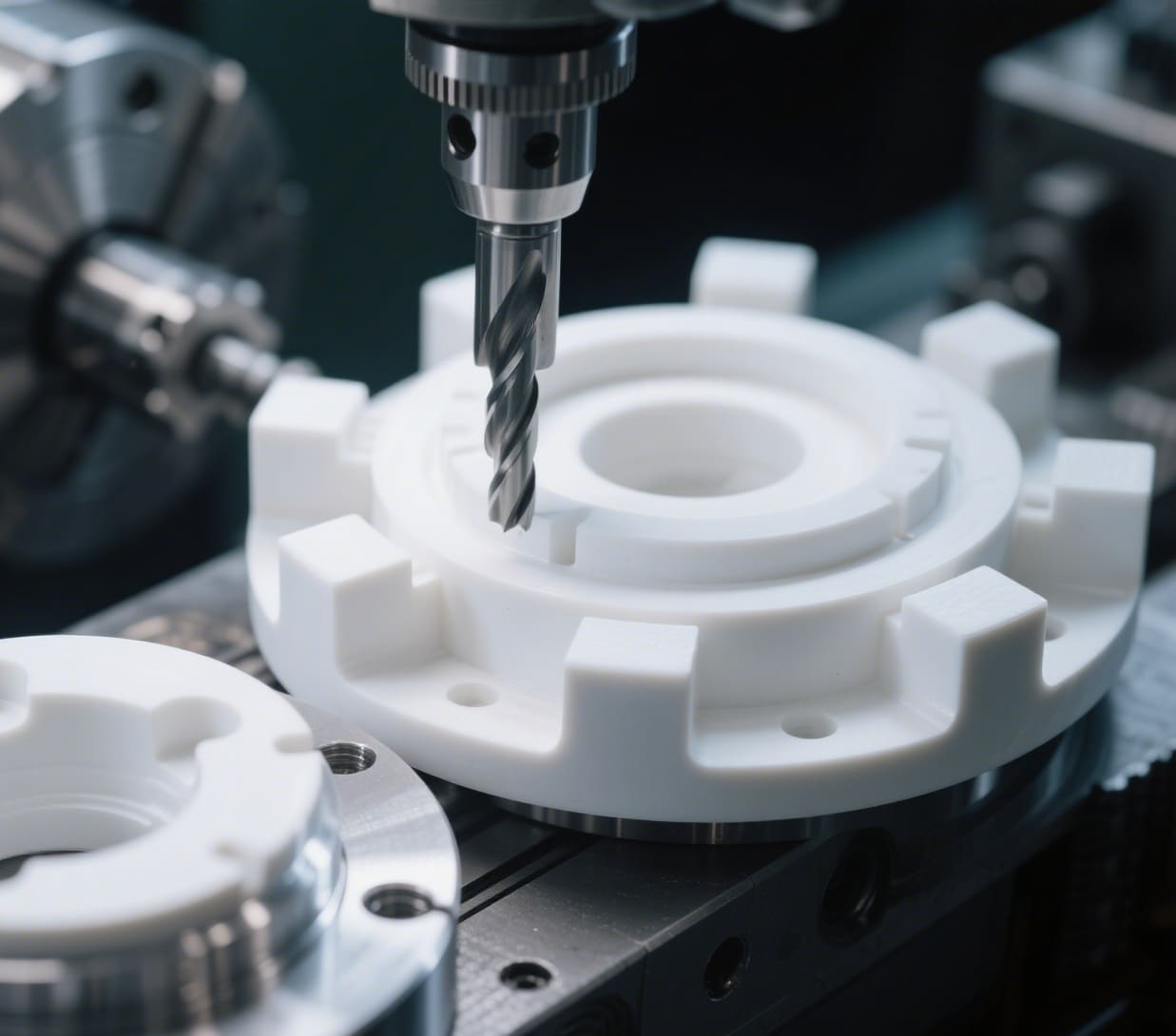

Beryllium Oxide (BeO) Ceramic is valued for its exceptional thermal conductivity, electrical insulation, and high melting point. These qualities make it widely used in electronics and high-temperature applications, but its hardness and brittleness require special machining approaches. Key machining considerations include:

- Cutting: Precision diamond-coated tools or laser cutting are essential to avoid microcracks and maintain clean edges, as BeO’s brittleness can lead to chipping during conventional cutting.

- Grinding: Fine diamond grinding wheels enable accurate shaping and surface finishing while minimizing the risk of fractures, especially important for small or complex parts.

- Drilling: Ultrasonic machining or abrasive waterjet methods are preferred to produce precise holes without causing thermal damage or cracks.

- Surface Finishing: Polishing techniques enhance surface smoothness and electrical insulation properties, crucial for applications demanding high dielectric performance and reliability.

Beryllium Oxide Ceramic Packaging

Beryllium oxide ceramic products are typically packaged in vacuum-sealed bags to prevent moisture or contamination and wrapped with foam to cushion vibrations and impacts during transport, ensuring the quality of products in their original condition.

Download

Get A Quote

We will check and get back to you in 24 hours.