Aluminum Nitride Washer

Aluminum Nitride Washer

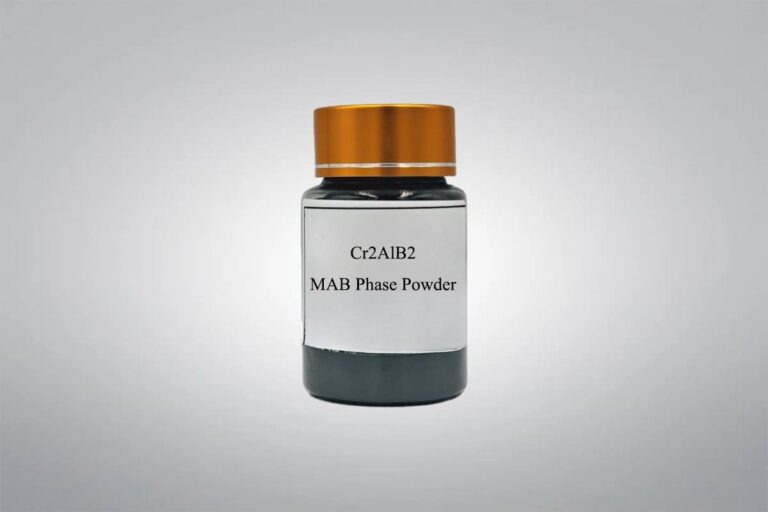

Purity: 95%-99%

Aluminum Nitride Washer is a high-performance ceramic component with exceptional thermal conductivity, electrical insulation, high-temperature resistance, and chemical stability. It plays a crucial role in electronics, aerospace, and semiconductor maufacturing. As a leading supplier and manufacturer of premium aluminum nitride products, we can supply high-quality aluminum nitride washers with various specifications and competitive prices, offering customized solutions to meet specific requirements.

Or email us at sales@heegermaterials.com.Aluminum Nitride Washer Data Sheet

| Reference Code: | HM1922 |

| Purity: | 95%-99% |

| Density: | 3.32 g/cm3 |

| Appearance: | Dark Gray / Light Gray / Beige |

| Shape: | Cylinder, Conical Cylinder, Rectangular, T-shape, or Customized according to specific drawings. |

| Surface Roughness: | Ra: 0.3-0.5 μm |

| Machining Precision: | 0.01 mm |

Aluminum Nitride Washer

Aluminum Nitride (AlN) is made of high-purity aluminum nitride ceramic, exhibiting high temperature resistance, corrosion resistance, and excellent thermal conductivity. It is widely used in the electronics industry (e.g., power modules and LED packaging), high-temperature equipment, and microelectronics packaging for heat dissipation, insulation, and support. Advanced Ceramics Hub We can offer both bulk molding and custom single-piece options to meet diverse industrial and research requirements, with flexible and rapid customization of product size and scale.

Aluminum Nitride Washer Advantages

- High thermal conductivity (170-230 W/mK), up to 9.5 times that of alumina.

- A thermal expansion coefficient similar to that of silicon (Si).

- Superior electrical insulation and lower dielectric constant.

- Higher mechanical strength (450 MPa).

- Excellent resistance to molten metal corrosion.

- High purity and non-toxic.

Aluminum Nitride Washer Applications

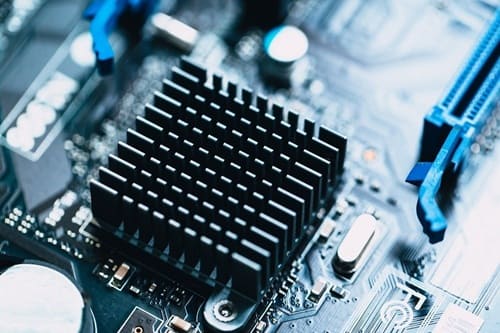

- Electronics Industry: Thanks to their high thermal conductivity and electrical insulation, AlN washers are commonly used in semiconductor devices, LED packaging, and power modules as heat-dissipating gaskets.

- High-Temperature Environments: With excellent high-temperature resistance and thermal shock resistance, AlN washers are employed in high-temperature furnaces or heat treatment equipment as insulating and supporting components.

- Chemical Industry: The chemical stability of aluminum nitride makes it suitable for washers in corrosive environments, such as chemical reactors or molten metal processing.

- Aerospace: In applications requiring lightweight, high-temperature resistance, and thermal management—such as aerospace engine components—AlN washers are an ideal choice.

- Microelectronics Packaging: Used in microwave devices and integrated circuits, AlN washers provide thermal management while maintaining electrical insulation.

Aluminum Nitride Material Properties

Aluminum Nitride Material Grades

HMAN1000 is our standard high purity aluminium nitride with a thermal conductivity of 170 W/mK. This is the same thermal performance as our substrate material but offers the possibility of larger pieces in length/width and in thicknesses up to 30mm.

HMAN1000 has good coefficient of thermal expansion – matched to silicon and gallium nitride over wide temperature ranges.

HMAN100 Applications:

- High power insulators

- Laser components

- Water cooled heatsinks

- Power electronics

- Aerospace, medical and semiconductor components

HMAN1000S 170 W/mK is our standard high thermal conductivity substrate material, However, other high-performance grades are also available.

HMAN1000S Applications:

- Heat sinks

- Heat spreaders

- Laser heatsinks power rectifiers

- Aerospace, power electronics, rectifiers

HMAN2000 is one of our enhanced grades of aluminium nitride, offering all the mechanical performance of HMAN1000 with the enhanced benefits of 200 W/mK thermal conductance.

HMAN2000 Applications:

- Heat sinks

- Heat spreaders

- Laser heatsinks power rectifiers

- Aerospace, power electronics, rectifiers

HMAN3000 is one of our enhanced grades of aluminium nitride offering, all the mechanical performance of HMAN1000 with the enhanced benefits of 230 W/mK thermal conductance.

HMAN3000 Applications:

- Heat sinks

- Heat spreaders

- Laser heatsinks power rectifiers

- Aerospace, power electronics, rectifiers

HMAN4000 is one of our enhanced grades of aluminium nitride offering, all the mechanical performance of HMAN1000 with the enhanced benefits of 200 W/mK thermal conductance.

HMAN4000 Applications:

- Heat sinks

- Heat spreaders

- Laser heatsinks power rectifiers

- Aerospace, power electronics, rectifiers

Aluminum Nitride Ceramic Machining

Aluminum Nitride (AlN) ceramic machining is a precise process used to fabricate high-performance components from aluminum nitride materials. Machining aluminum nitride ceramics requires specialized equipment and techniques to handle their brittleness and hardness. Proper tooling and controlled environments are essential to avoid material damage and achieve the desired surface finish and dimensional accuracy. The common machining methods are as follows:

- Diamond Cutting: Diamond tools are used to achieve fine precision and smooth surface finishes, ideal for complex shapes.

- Laser Cutting: A non-contact method used for intricate shapes, with high precision and minimal thermal impact.

- Precision Grinding: Utilized to achieve fine tolerances and surface finishes. Requires special care to prevent cracking or chipping due to the ceramic’s brittleness.

- Wire EDM (Electrical Discharge Machining): A method often used for intricate cutting, especially for thin and complex geometries.

Aluminum Nitride Ceramic Packaging

Aluminum Nitride Ceramic products are typically packaged in vacuum-sealed bags to prevent moisture or contamination and wrapped with foam to cushion vibrations and impacts during transport, ensuring the quality of products in their original condition.

Download

Get A Quote

We will check and get back to you in 24 hours.