Aluminum Nitride Granulation Powder

Aluminum Nitride Granulation Powder

Purity: 99%-99.9%

Particle Size: 30-120 μm, or customized

Aluminum Nitride Granulation Powder is a high-performance ceramic material, offering excellent formability and flowability. It is suitable for processes such as dry pressing, semi-dry pressing, and cold isostatic pressing. As a leading supplier and manufacturer of premium aluminum nitride products, we can supply high-quality aluminum nitride granulation powders with various specifications and competitive prices, offering customized solutions to meet specific requirements.

Or email us at sales@heegermaterials.com.Aluminum Nitride Granulation Powder Data Sheet

| Reference Code: | HM1912 |

| Purity: | 99%-99.9% |

| Particle Size: | 30-120 μm or customized |

| CAS: | 24304-00-5 |

| Melting Point: | 2200℃ |

| Boiling Point: | 2249℃ |

Aluminum Nitride Granulation Powder

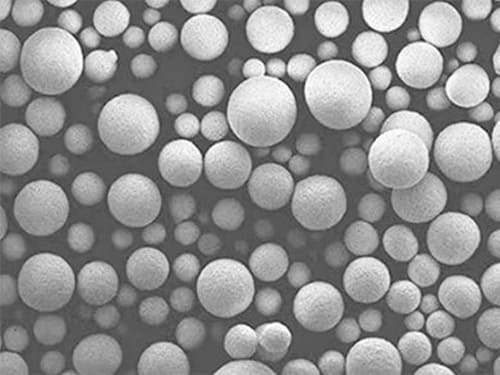

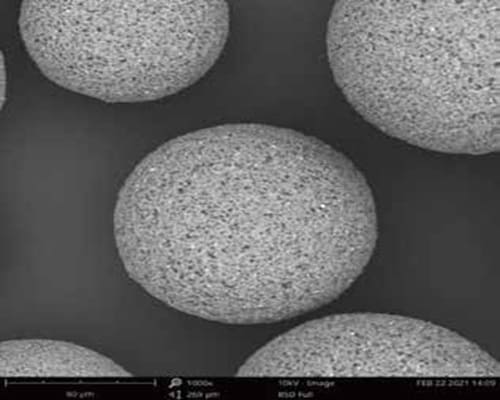

Aluminum Nitride Granulation Powder is manufactured by micron powder spray granulation and contains binders and sintering aids. It has good flowability, ensuring complete mold filling. The pressed body has no defects, with uniform and consistent density. It is primarily designed for dry pressing, semi-dry pressing, and cold isostatic pressing processes. Advanced Ceramics Hub can provide customized solutions in purity and particle size to meet various industrial and research applications.

Aluminum Nitride Granulation Powder Specifications

| Product | AlN Granulation Powder-1 | AlN Granulation Powder-2 | |

| Average Particle Size (μm) | 40-60 | 8-15 | |

| Sphericity | 40-60% | ≥98% | |

| Y2O3 (wt%) | 3-4 | 4-5 | |

| Impurity Content | Ca (ppm) | <30 | <50 |

| Fe (ppm) | <15 | <20 | |

| Si (ppm) | <40 | <50 | |

| Apparent Density (g/cm3) | 0.8-1.0 | 0.8-1.0 | |

| Hall Flow Rate (s/50g) | 80-100 | 80-100 | |

| Recommended Sintering Temperature | 1750-1850 ℃ | ||

| Note | Sintering additives can be formulated according to customer requirements. | ||

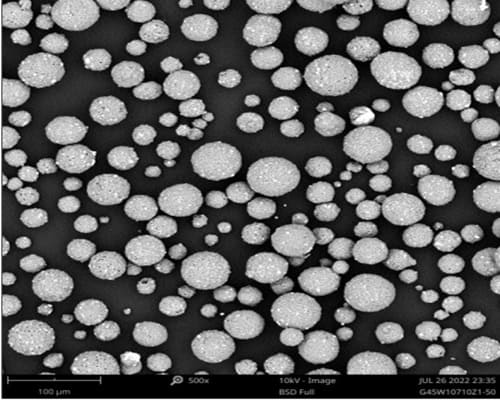

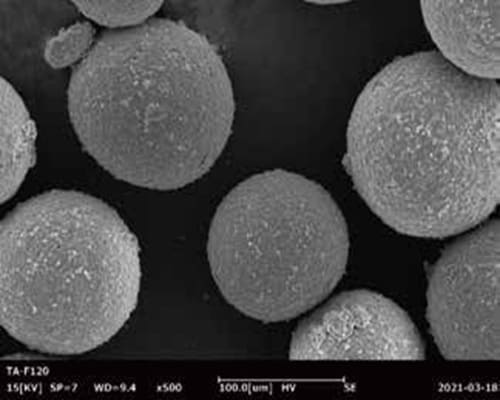

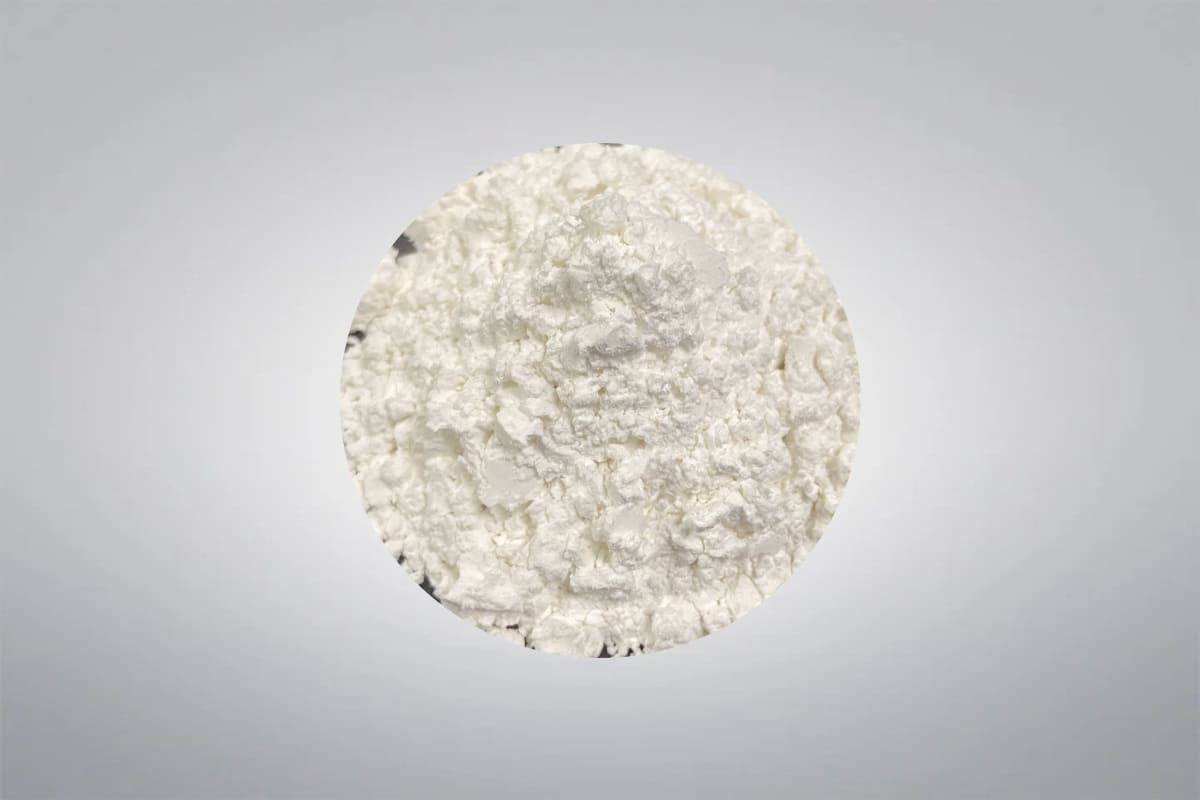

Aluminum Nitride Granulation Powder Morphology

Aluminum Nitride Granulation Powder Features

- Good sphericity

- High sintering activity

- Excellent flowability

- High strength

Aluminum Nitride Powder Solutions

Granulation Powder

Aluminum Nitride Granulation Powder, with excellent formability and flowability, is ideal for dry pressing, semi-dry pressing, and cold isostatic pressing, used in electrostatic chucks and ceramic components.

Aluminum Nitride Granulation Powder Applications

- Electronics & Semiconductor Industry

- Ceramics Manufacturing

- Advanced Sintering Processes

- LED & Optoelectronics

- Aerospace & Automotive Applications

Aluminum Nitride Granulation Powder Packaging

The Aluminum Nitride Granulation Powder is carefully placed in wooden cases or cartons with additional support from soft materials to prevent any shifting during transportation. This packaging method guarantees the integrity of the products throughout the delivery process.

Download

Get A Quote

We will check and get back to you in 24 hours.