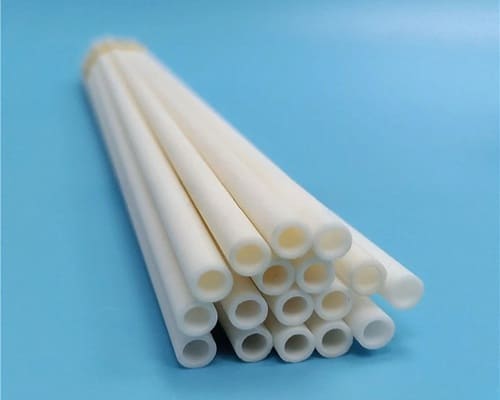

Alumina Tube

Alumina Tube

Purity: 95%, 96%, 99%, 99.5%, 99.7%, 99.95%

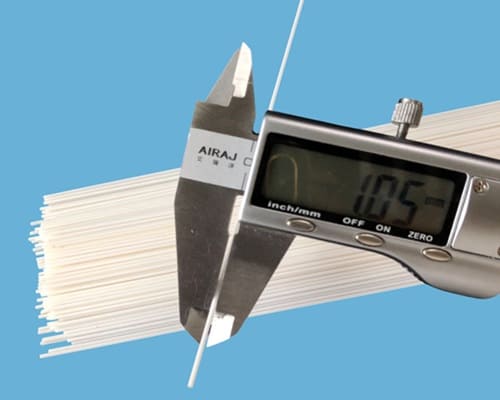

Diameter: 1-150 mm, or customized

Alumina Tube is a high-performance ceramic material primarily composed of alumina with the purity ranging from 90%-99.9%. The additives is designed to enhance its properties. As a leading supplier and manufacturer of premium alumina products, we can supply high-quality alumina tubes with various specifications and competitive prices, offering customized solutions to meet specific requirements.

Or email us at sales@heegermaterials.com.Alumina Tube Data Sheet

| Reference Code: | HM1976 |

| Purity: | 95%, 96%, 99%, 99.5%, 99.7%, 99.95% |

| Color: | White |

| Density: | 3.7-3.98 g/cm3 |

| Outer Diameter: | 1-150 mm, or customized |

| Inner Diameter: | 0.5-140 mm, or customized |

| Wall Thickness: | 0.25-15 mm, or customized |

| Length: | 1-1000 mm, or customized |

Alumina Tube

Alumina Tube is made from high-purity aluminum oxide (Al2O3) with typical purities ranging from 90%-99.9%. It has exceptional high-temperature resistance, corrosion resistance, and mechanical strength. With a smooth surface, high hardness, and excellent electrical insulation properties, it performs reliably in demanding conditions. Advanced Ceramics Hub can supply customized solutions for diameter, wall thickness, length, and surface finish to meet diverse industrial and research requirements.

Alumina Tube Alumina Tube Alumina Tube Alumina Capillary Tube Alumina Capillary Tube

Alumina Tube Specifications

| Outer Diameter: | Φ1-150 mm |

| Inner Diameter: | Φ0.5-140 mm |

| Wall Thickness: | 0.25-15 mm |

| Length: | 1-1000 mm |

| Note: Customized services can be available according to specific drawings. | |

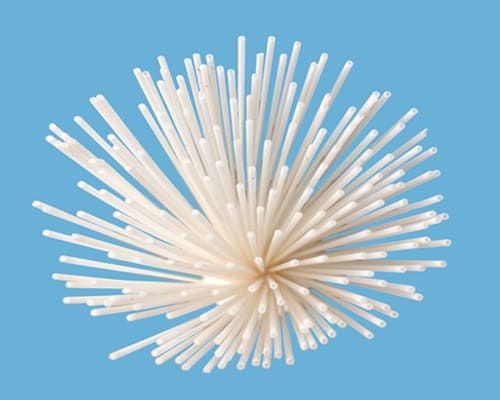

Multi-Bore Alumina Tube

Multi-bore alumina ceramic tubes are primarily used as thermocouple protection tubes to protect temperature-sensing elements from corrosion, oxidation, or damage by external substances during use. They are suitable for temperature measurement in air, steam, hydrogen, argon, carbon monoxide, and vacuum environments within the range of 600-1700°C. These tubes come in dual, four, and multi-hole configurations, with a minimum hole diameter of 0.5 mm and lengths up to 2600 mm. Customization is available based on specific customer requirements.

Alumina Tube Advantages

- Excellent electrical insulation properties

- High hardness and mechanical strength

- Wear and abrasion-resistant

- High thermal conductivity and thermal shock resistance

- Low density

- Resistant to strong acid and alkali attack at high temperatures

- Transparent to microwave radio frequencies

- High compressive and dielectric strength

- Very specific thermal conductive and thermal expansion rates

Alumina Tube Applications

- High-Temperature Furnace Linings and Thermocouple Protection: Used as linings in high-temperature furnaces (e.g., lab or industrial kilns) or as protective sleeves for thermocouples, withstanding up to 1700°C with strong thermal stability.

- Corrosion-Resistant Pipelines in Chemical Industry: Employed to transport corrosive gases or liquids, leveraging alumina’s exceptional resistance to acids and alkalis.

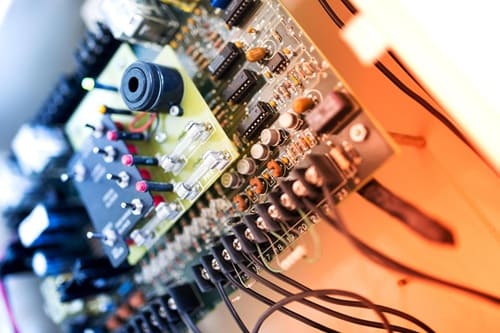

- Electronic Insulation Components: Serve as insulating tubes in electronic devices to protect wires or components, benefiting from high electrical insulation (dielectric strength up to 20 kV/mm).

- Wear-Resistant Mechanical Parts: Made into wear-resistant sleeves or pipes for high-abrasion environments, such as mining or powder transport systems, due to their high hardness (Mohs 9).

- Medical and Laboratory Equipment: Used in catheters or reaction tubes for precision instruments, owing to their biocompatibility and chemical inertness, ideal for biological experiments or dental applications.

- Vacuum and Plasma Systems: Applied as structural components in vacuum furnaces or plasma equipment, thanks to their low porosity and stability at high temperatures.

Alumina Material Properties

Alumina Material Grades

It has a very high purity (99.95%) grade of Alumina (Aluminum Oxide) exhibiting an exceptional combination of mechanical and electrical properties. It features very high hardness, exceptional electrical resistivity, high-temperature mechanical stability and strength in addition to corrosion resistance and bio/chemical inertness.

Its high-temperature stability and electrical stability make it particularly suitable for high-temperature applications such as high voltage/frequency insulators, heating elements supports, etc

Physical Properties:

- Color: White

- Density: 3.98 g/cm3

Applications:

- High-temperature electrical insulators

- Very high voltage/frequency insulators

- Machine components where high wear resistance

is required in an oxidizing environment - Precision shafts in high-wear condition

- Unlubricated (vacuum) or gas/water lubricated

high speed sliding bearings - Shot blast nozzles

- Abrasive flow deflector plates/cones

- Valve seats

- Wire guides

It’s a high-purity grade of Alumina (Aluminum Oxide) and one of the high-performance grades in this range of materials. It features a 99.7% purity Alumina base material that provides a superior set of mechanical and electrical properties while maintaining a reasonable cost. It is a very hard-wearing technical ceramic offering and is ideally suited to a wide range of industrial applications where mechanical and electrical performance is of the essence and the material needs to perform adequately in aggressive environments.

It can be machined in the “green state”- that is before sintering takes place, thus ensuring a large variety of shapes and sizes. It can also be diamond ground to tight tolerances in the fully sintered state using diamond grinding.

Physical Properties:

- Color: Ivory

- Density: 3.9 g/cm3

Applications:

- Electronic components & substrates

- High-temperature electrical insulators

- High voltage insulators

- Laser tubes

- Machined components

- Mechanical seals

- Precision shafts and axles in high-wear environments

- Roller and ball bearings

- Seal rings

- Semiconductor parts

- Shot blast nozzles

- Thermocouple tubes

- Tap plates

- Valve seats

- Wear components

- Wire and thread guides

- Ballistic Armor

99.5% Purity Alumina is a high-performance engineering material with exceptional mechanical strength, high-temperature resistance, and excellent electrical insulation properties. It is widely used in industrial equipment, electronic components, medical devices, and aerospace applications.

Physical Properties:

- Color: Ivory

- Density: 3.9 g/cm3

Applications:

- Electronic components & substrates

- High-temperature electrical insulators

- High voltage insulators

- Laser tubes

- Machined components

- Mechanical seals

- Precision shafts and axles in high-wear environments

- Roller and ball bearings

- Seal rings

- Semiconductor parts

- Shot blast nozzles

- Thermocouple tubes

- Tap plates

- Valve seats

- Wear components

- Wire and thread guides

- Ballistic Armor

99% Purity Alumina Is a premium industrial ceramic material with excellent mechanical properties, ultra-high hardness, high-temperature resistance, and insulation performance. It can maintain stable chemical and physical properties even in extreme environments, making it widely used in semiconductors, electronic components, laser technology, and aerospace.

Physical Properties:

- Color: Ivory

- Density: 3.85 g/cm3

Applications:

- Electronic components & substrates

- High-temperature electrical insulators

- High voltage insulators

- Laser tubes

- Machined components

- Mechanical seals

- Precision shafts and axles in high-wear environments

- Roller and ball bearings

- Seal rings

- Semiconductor parts

- Shot blast nozzles

- Thermocouple tubes

- Tap plates

- Valve seats

- Wear components

- Wire and thread guides

- Ballistic Armor

It is a regular purity grade Alumina (Aluminum Oxide) and it is one of the workhorses of the technical ceramics industry. It features a 96% purity Alumina base material providing a balanced “cost to quality” ratio. It is a hard-wearing technical ceramic offering an excellent combination of both mechanical and electrical properties and is ideally suited to a wide range of industrial applications where cost is of the essence, but the material still needs to perform adequately from a mechanical and electrical standpoint.

It can be machined in the “green state”- that is before sintering takes place, thus ensuring a large variety of shapes and sizes. It can also be diamond ground to tight tolerances in the fully sintered state using diamond grinding.

Physical Properties:

- Color: White

- Density: 3.75 g/cm3

Applications:

- Electronic components & substrates

- High-temperature electrical insulators

- High voltage insulators

- Laser tubes

- Machined components

- Mechanical seals

- Precision shafts and axles in high-wear environments

- Roller and ball bearings

- Seal rings

- Semiconductor parts

- Shot blast nozzles

- Thermocouple tubes

- Tap plates

- Valve seats

- Wear components

- Wire and thread guides

- Ballistic Armor

95% Purity Alumina is an economical and practical engineering material. Its slightly lower alumina content reduces production costs while maintaining decent wear resistance and processing flexibility. It is commonly used in mechanical parts, electrical insulators, and wear-resistant bushings, offering an excellent cost-performance balance.

Physical Properties:

- Color: White

- Density: 3.7 g/cm3

Applications:

- Electronic components & substrates

- High-temperature electrical insulators

- High voltage insulators

- Laser tubes

- Machined components

- Mechanical seals

- Precision shafts and axles in high-wear environments

- Roller and ball bearings

- Seal rings

- Semiconductor parts

- Shot blast nozzles

- Thermocouple tubes

- Tap plates

- Valve seats

- Wear components

- Wire and thread guides

- Ballistic Armor

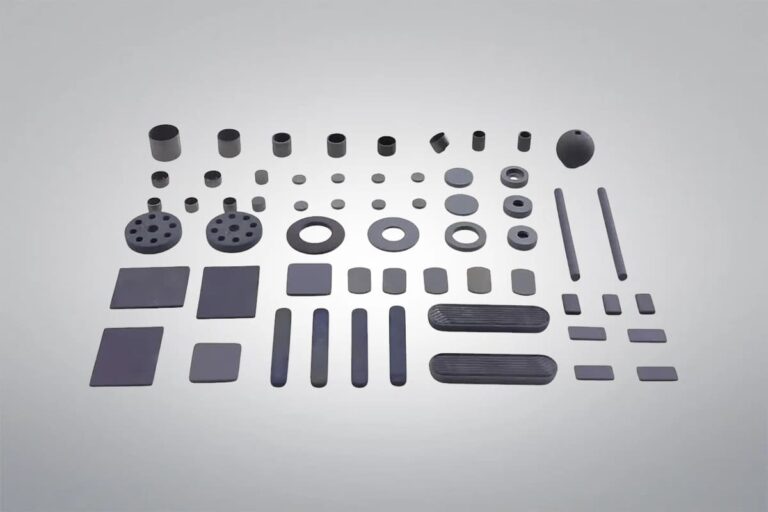

Alumina Ceramic Machining

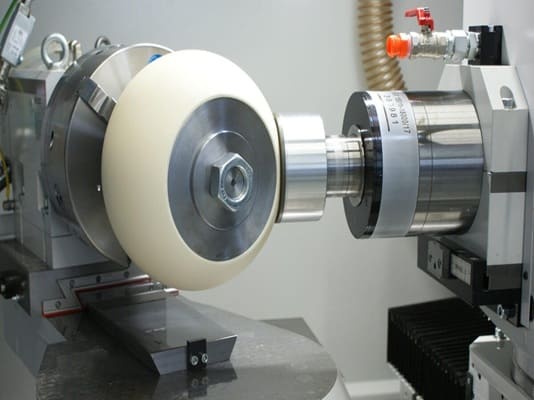

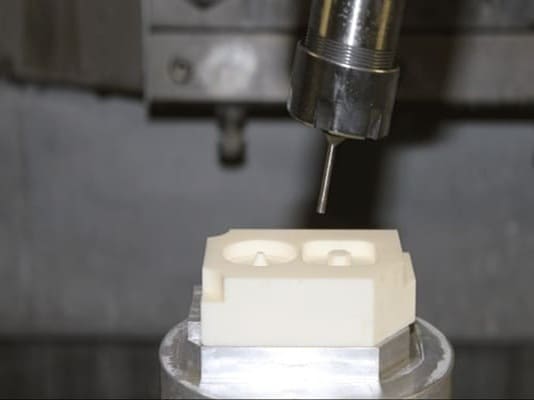

Alumina ceramics are produced through methods such as injection molding, die pressing, isostatic pressing, slip casting, and extrusion. After sintering and densification, machining requires diamond grinding techniques. Advanced Ceramic Hub utilizes cutting-edge green and biscuit machining technology to produce more complex components with traditional methods. Our advanced machining center includes drilling, grinding, milling, polishing, sawing, tapping, threading, and turning, enabling the manufacture of alumina ceramic components with tight tolerances and high complexity. During the machining process, the following precautions should be observed:

- Shrinkage Control: Alumina ceramics shrink by about 20% during sintering, requiring dimensional adjustments in the green body stage.

- Tolerance Control: Precise tolerances are unachievable in the green or pre-sintered state; fine machining should follow sintering.

- Diamond Grinding: Post-sintering, high-hardness alumina requires diamond grinding, as conventional methods fall short.

- Tool Selection: Diamond-coated tools or grinding wheels are essential to handle ceramic hardness and prevent tool damage.

- Temperature Control: Strict temperature management during sintering prevents cracking or deformation.

- Stress Management: Excessive stress during machining must be avoided to prevent brittle failure.

- Cutting Speed and Feed Rate: Controlled speeds and feeds ensure quality and extend tool life.

- Surface Treatment: Post-machining polishing removes defects, enhancing performance and appearance.

Alumina Ceramic Packaging

Alumina Ceramic products are typically packaged in vacuum-sealed bags to prevent moisture or contamination and wrapped with foam to cushion vibrations and impacts during transport, ensuring the quality of products in their original condition.

Download

Get A Quote

We will check and get back to you in 24 hours.