Alumina Near-Spherical Powder

Alumina Near-Spherical Powder

Purity: 99.9%-99.999%

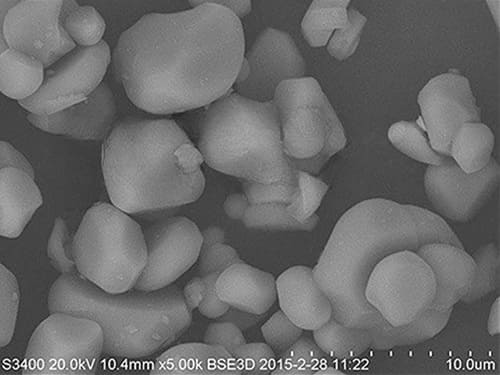

Morphology: Near-spherical

Alumina Near-spherical Powder is a high-performance inorganic material with excellent physical and chemical properties, featuring good flowability and high packing density. It is widely used in ceramics, abrasives, catalyst supports, and thermal spraying applications. As a leading supplier and manufacturer of premium alumina products, we can supply high-quality alumina powders with various specifications and competitive prices, offering customized solutions to meet specific requirements.

Or email us at sales@heegermaterials.com.Alumina Near-Spherical Powder Data Sheet

| Reference Code: | HM1970 |

| Purity: | 99.9%-99.999% |

| Morphology: | Near-spherical |

| Appearance: | White Powder |

Alumina Near-Spherical Powder

Alumina Near-Spherical Powder is a white powder with a purity of 99.9% to 99.999%. It has a high α-phase content, excellent stability, high crystallinity, and uniform particle size, making it widely applied in thermal conductive materials, lithium-ion battery separator coatings, precision polishing, and ceramic membranes. Advanced Ceramics Hub can supply high-quality alumina (Al2O3) powder in the form of near-spherical, spherical, irregular, and nano-scale particles to meet diverse industrial and research requirements.

Alumina Near-Spherical Powder Specifications

| Product | Particle Size (D50) | PH | Morphology | Specific Surface Area | Electricity Conductivity | Moisture | SiO₂ | Fe₂O₃ | Na₂O |

| μm | – | – | ㎡/g | μS/cm | % | ppm | ppm | ppm | |

| NSAR-05 | 0.6 | 8.52 | Near-spherical | 4.4 | 30.52 | 0.1 | 466 | 92 | 81 |

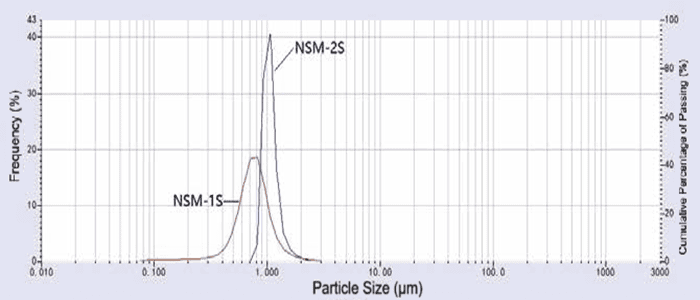

| NSM-1S | 0.69 | 8.69 | Near-spherical | 4.24 | 23.03 | 0.07 | 234 | 113 | 56 |

| NSM-2S | 1.05 | 8.57 | Near-spherical | 2.40 | 16.34 | 0.08 | 310 | 95 | 26 |

Aluminum Near-Spherical Powder Particle Size Distribution (PSD)

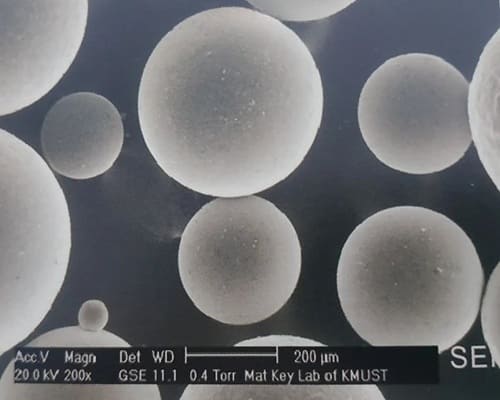

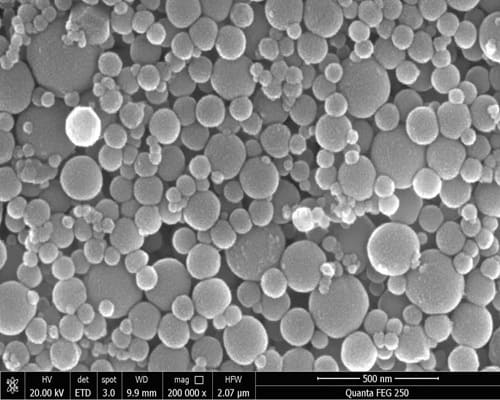

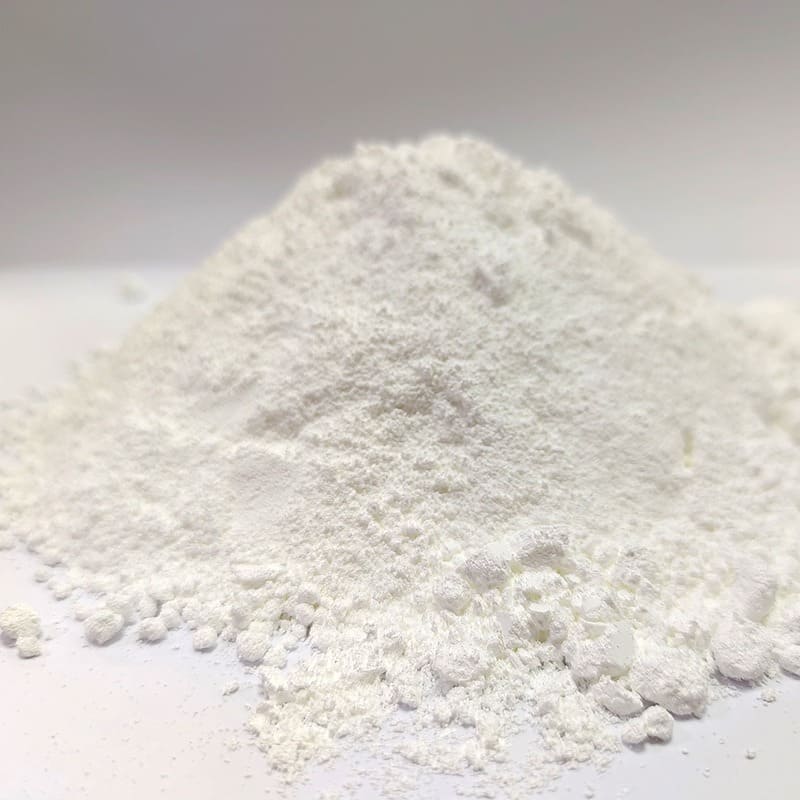

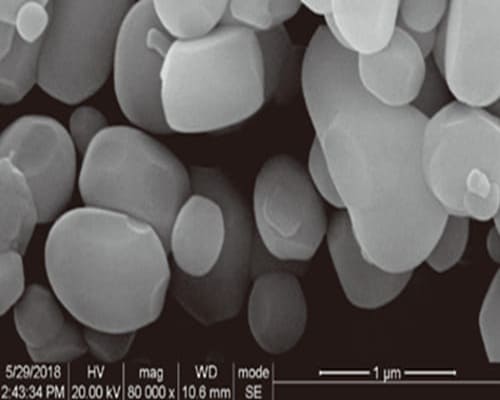

Alumina Near-Spherical Powder Morphology

Alumina Powder Fine Particle Solutions

Near-Spherical Powder

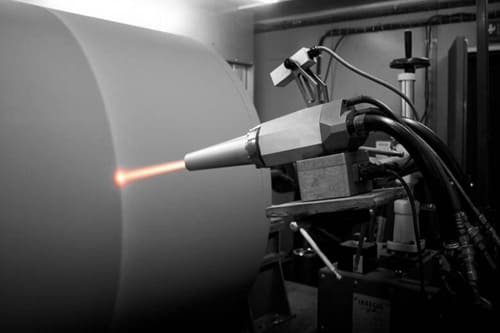

Near-spherical Alumina Powder has a high α-phase content. It offers excellent flowability, dispersibility, and packing density, making it ideal for high-performance ceramics, thermal spray coatings, electronic fillers, and precision polishing.

Alumina Near-Spherical Powder Advantages

- High purity

- Excellent flowability

- High packing density

- Uniformity and consistency

- High alpha phase, high crystallinity

- Low impurities

Alumina Near-Spherical Powder Applications

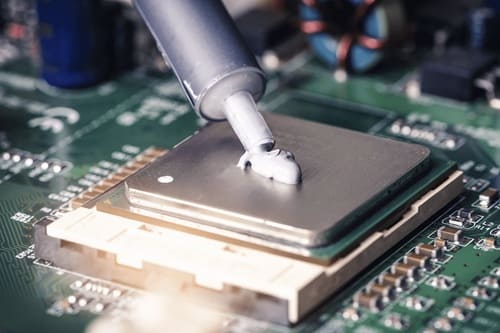

- Thermally conductive engineering plastics

- Thermal interface materials

- Ceramic film coatings for lithium batteries

Alumina Near-Spherical Powder Packaging

The Alumina Near-spherical Powder is carefully placed in wooden cases or cartons with additional support from soft materials to prevent any shifting during transportation. This packaging method guarantees the integrity of the products throughout the delivery process.

Download

Get A Quote

We will check and get back to you in 24 hours.