Thermal Interface Materials for High-Power Chips (200W–400W): Ensuring Performance and Reliability

The rise of artificial intelligence, high-performance servers, cryptocurrency mining, and professional workstations has driven chip power consumption to unprecedented levels. Processors and GPUs operating in the 200W–400W range are no longer rare; they have become standard in AI accelerators, data center CPUs, and advanced gaming hardware. This dramatic increase in power density brings a critical challenge: efficient heat dissipation.

Without proper thermal management, chip temperatures can climb by 20–30°C, causing performance throttling, reduced energy efficiency, and even early device failure. The microscopic gaps between a silicon chip and its cooling solution create thermal resistance that weakens overall stability. To address this, Thermal Interface Materials (TIMs) play a vital role. In this article, we explore how TIMs optimize high-power chip performance, covering their fundamentals, importance for 200W–400W devices, material categories, ceramic-based advantages, industry applications, future innovations, and practical FAQs.

At Advanced Ceramics Hub, we specialize in high-quality ceramic products, ensuring optimal performance for industrial and scientific applications.

What Are Thermal Interface Materials and How Do They Work?

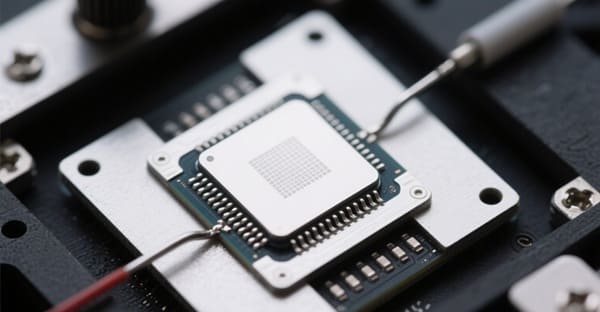

Thermal Interface Materials (TIMs) are specialized compounds designed to improve heat transfer between a heat source (such as a CPU or GPU) and a cooling solution (such as a heatsink, vapor chamber, or water block). Even the most finely machined metal surfaces contain microscopic air gaps, and because air is a poor conductor (≈0.026 W/m·K), these voids drastically reduce thermal efficiency. TIMs fill these gaps, creating a continuous heat conduction pathway.

Key Functions of TIMs:

- Minimize thermal resistance between the chip and the cooler

- Compensate for surface roughness and imperfections

- Enhance long-term stability in demanding conditions

- Allow for uniform heat spreading across larger surfaces

Common Thermal Conductivity Ranges:

| Material Type | Thermal Conductivity (W/m·K) | Typical Use Case |

| Thermal Grease | 1–8 | General CPU/GPU cooling |

| Thermal Pads | 1–6 | Large gaps, VRMs, chipsets |

| Phase-Change Materials (PCM) | 3–10 | High-precision server chips |

| Thermal Gel | 3–8 | Long-term, high-power ASICs |

| Metal Foils (Indium, Copper) | 80–400 | Extreme-performance systems |

In short, TIMs transform an imperfect physical connection into a high-efficiency thermal bridge, which is essential for chips in the 200W–400W power class.

Why Are Thermal Interface Materials Critical for 200W–400W Chips?

The higher the power consumption, the greater the thermal stress on the chip package and cooling system. At 200W–400W, the heat flux density can exceed 100 W/cm², which is comparable to the heat intensity of a rocket nozzle. Without TIMs, even the most advanced water-cooling systems fail to maintain safe operating temperatures.

Example: High-Power Devices

| Device | Chip Power | Application | Without TIM Temperature Rise | With TIM Temperature Rise |

| AMD EPYC 7513 CPU | 200W | Data center server | +30°C | +12°C |

| NVIDIA H20 GPU | 400W | AI inference | +35°C | +15°C |

| Intel Xeon W9-3400 | 350W | Professional workstation | +28°C | +13°C |

Benefits of TIMs in High-Power Chips:

- Reduce junction temperature by 15–20°C

- Prevent thermal throttling, preserving performance

- Extend chip lifespan by up to 2×

- Enable stable 24/7 operation in servers and AI clusters

Thus, TIMs are not optional—they are the gatekeepers of chip reliability at extreme power levels.

What Types of Thermal Interface Materials Are Used in High-Power Electronics?

Different categories of TIMs serve different needs. For 200W–400W chips, material selection depends on conductivity, stability, gap thickness, and reusability.

Main TIM Categories:

Thermal Grease (1–8 W/m·K)

- Composition: Silicone oil + oxide fillers (Al₂O₃, ZnO, Ag)

- Pros: High spreadability, low cost

- Cons: Drying and pumping out over time

Thermal Pads (1–6 W/m·K)

- Composition: Silicone or rubber + BN/Al filler

- Pros: Easy installation, reusable

- Cons: Lower conductivity, thickness dependency

Phase Change Materials (3–10 W/m·K)

- Solid at room temp, melts during operation → excellent conformity

- Pros: High precision fit, no leakage

- Cons: Single-use in many cases

Thermal Gel (3–8 W/m·K)

- High viscosity, long-term stability

- Pros: Excellent gap filling, does not dry out

- Cons: Harder to remove

Metallic TIMs (80–400 W/m·K)

- Indium foil, copper sheets

- Pros: Unmatched conductivity

- Cons: Expensive, risk of chip cracking

TIM Selection Guide:

| TIM Type | Best For | Drawback |

| Grease | General CPUs & GPUs | Requires re-application |

| Pads | VRMs, uneven surfaces | Lower conductivity |

| PCM | High-end servers & AI chips | Limited reuse |

| Gel | ASICs, mining rigs | Difficult cleanup |

| Metal | Supercomputers, aerospace chips | High cost, risk of damage |

This variety ensures engineers can select the right TIM for the right application.

How Do Ceramic-Based Thermal Interface Materials Enhance Performance?

Ceramics play a special role in advanced TIM formulations. Fillers such as aluminum oxide (Al₂O₃), boron nitride (BN), and silicon nitride (Si₃N₄) are widely used due to their combination of thermal conductivity, electrical insulation, and chemical stability.

Why Use Ceramic-Based TIMs?

- High Thermal Conductivity:

- Al₂O₃: 30–40 W/m·K

- BN: 200–400 W/m·K

- Si₃N₄: 70–90 W/m·K

- Electrical Insulation: Prevents short circuits (resistivity >10¹³ Ω·cm)

- Stability: Resistant to oxidation and thermal cycling

- Cost Effectiveness: Cheaper than metallic TIMs

Ceramic-Based TIM Applications:

| Ceramic Filler | Application | Benefit |

| Al₂O₃ | PCM, grease | Balanced cost & performance |

| BN | High-power GPUs & AI chips | Very high conductivity |

| Si₃N₄ | Harsh environments | Strong mechanical stability |

Summary: Ceramic-based TIMs combine thermal efficiency and electrical insulation, making them especially attractive for server CPUs, GPUs, and power electronics.

Explore our high-quality ceramic products.

How Do Thermal Interface Materials Improve AI Servers and Data Centers?

AI data centers are pushing thermal design to the limit. A single NVIDIA H20 GPU at 400W TDP can generate as much heat as a household iron. With clusters containing sthousands of GPUs, cooling efficiency directly impacts performance and electricity bills.

TIM Benefits in Data Centers:

- Reduce cooling system workload → lower PUE (Power Usage Effectiveness)

- Enable higher rack density (more chips per rack without overheating)

- Increase system reliability for 24/7 workloads

Example Comparison:

| Without TIM | With Advanced TIM |

| GPU throttles at 80°C | GPU maintains <65°C |

| 15% performance loss | Full performance sustained |

| Fan speed +20% | Fan speed stable |

| Higher electricity cost | Lower operational cost |

TIMs are a silent but crucial enabler of AI progress—without them, training large language models or running massive inference jobs would be economically unfeasible.

How Do Thermal Interface Materials Compare with Other Cooling Solutions?

While TIMs are essential, they coexist with other cooling strategies such as air cooling, liquid cooling, vapor chambers, and immersion cooling.

Cooling Methods Comparison:

| Cooling Method | Role | Strength | Weakness |

| TIMs | Interface filler | Reduces thermal resistance | Needs proper selection |

| Air Cooling | Fans + heatsinks | Low cost, easy | Limited capacity >200W |

| Liquid Cooling | Water blocks + pumps | High efficiency | Complex installation |

| Vapor Chambers | Phase change heat spreaders | Excellent spreading | Expensive |

| Immersion Cooling | Full liquid bath | Extreme heat removal | Bulky, costly |

Key Point: Even the best liquid or immersion system cannot perform optimally without TIMs. They remain the first thermal bridge between chip and cooler.

What Are the Future Trends in Thermal Interface Materials?

As chips continue to scale, TIMs must evolve. Current research explores nanostructured composites, graphene-enhanced TIMs, and liquid metals.

Emerging TIM Technologies:

- Graphene-based TIMs: >1000 W/m·K conductivity in theory

- Liquid Metals (e.g., Ga-In alloys): Ultra-high conductivity, but risk of corrosion

- Hybrid Ceramic Composites: Combine ceramic insulation with metallic efficiency

- Eco-friendly TIMs: Recyclable, low-VOC, safer for manufacturing

Future TIMs will be designed not only for performance, but also for sustainability and manufacturability.

Request a custom quote for ceramic products.

FAQ

| Question | Answer |

| What TIM is best for a 400W GPU? | Phase change or high-end ceramic-filled grease |

| How often should TIM be replaced? | Grease: 12–24 months; Gel/PCM: 3–5 years |

| Can ceramic-based TIMs outperform metals? | Not in conductivity, but they offer insulation and lower cost |

| Are TIMs reusable? | Pads and gels are reusable; grease and PCM usually are not |

| Do TIMs affect overclocking? | Yes, high-end TIMs can lower temps by 10–15°C |

| Can TIMs fail? | Yes, drying, pump-out, or oxidation may occur |

| Are TIMs safe for all chips? | Yes, especially ceramic-filled types that are electrically insulating |

Conclusion

In the race toward ever more powerful processors, heat has become the ultimate bottleneck. For chips operating at 200W–400W, the difference between a stable, efficient system and a throttling, unreliable one often comes down to the quality of the Thermal Interface Material.

From traditional thermal grease to advanced ceramic-filled composites and future graphene-based solutions, TIMs are the invisible backbone of high-performance electronics. For engineers, researchers, and manufacturers, choosing the right TIM is no longer optional—it is a strategic decision that defines efficiency, reliability, and cost-effectiveness.

Looking for high-quality ceramic products? Contact us today!