Advanced Ceramics: A New Core in Industrial Materials

Advanced ceramics, also known as high-performance or technical ceramics, represent a class of engineered inorganic compounds designed with exceptional mechanical, thermal, electrical, optical, and biological properties. Unlike traditional ceramics, which typically rely on natural clays and minerals, advanced ceramics are fabricated from ultra-pure, finely synthesized powders that undergo precise and tightly controlled processing methods. This meticulous approach results in materials that offer superior strength, hardness, corrosion resistance, and biocompatibility. Their unparalleled characteristics make advanced ceramics indispensable in a wide array of critical industrial sectors, including aerospace, defense, electronics, biomedical engineering, and sustainable energy. As the demands for performance and miniaturization increase, advanced ceramics serve as the backbone of next-generation industrial materials, enabling technologies that push the limits of what conventional materials can achieve.

At Advanced Ceramic Hub, we specialize in high-quality advanced ceramic products, ensuring optimal performance for industrial and scientific applications.

What Are the Two Main Categories of Advanced Ceramics and Their Characteristics?

Advanced ceramics can be broadly classified into two primary categories: structural ceramics and functional ceramics. Each category is distinguished by its specific properties, material compositions, and applications.

| Category | Key Characteristics | Main Materials | Typical Applications |

| Structural Ceramics | High mechanical strength, hardness, wear, and heat resistance | Silicon Nitride (Si3N4), Silicon Carbide (SiC), Zirconia (ZrO2), Boron Carbide (B4C), Titanium Diboride (TiB2), Alumina (Al2O3), Sialon | Cutting tools, engine parts, armor, pumps |

| Functional Ceramics | Electronic, magnetic, optical, superconductive, and biocompatible properties | Barium Titanate (BaTiO3), Lead Zirconate Titanate (PZT), Yttria-Stabilized Zirconia (YSZ), Aluminum Nitride (AlN), Ferrites, High-temperature superconductors | Sensors, capacitors, insulators, and biomedical implants |

Structural ceramics are primarily designed for applications where mechanical durability, wear resistance, and thermal stability are critical. In contrast, functional ceramics exhibit specialized properties such as piezoelectricity, ferroelectricity, magnetism, or biocompatibility, which are leveraged in advanced electronic and medical devices. Understanding these categories is essential for selecting the appropriate ceramic materials tailored to specific industrial demands.

Explore our high-quality advanced ceramic products.

What Are the Main Structural Advanced Ceramics and Their Unique Properties?

Structural ceramics are engineered to withstand harsh mechanical stresses and extreme environments. Their inherent high hardness, fracture toughness, and thermal shock resistance make them ideal for demanding industrial components.

| Material | Description | Performance Highlights | Industrial Uses |

| Silicon Nitride (Si3N4) | Fiber-reinforced and phase-stabilized for toughness | Fracture toughness improved up to 5× with ZrO2 doping | Cutting tools, engine components |

| Silicon Carbide (SiC) | Hot-pressed dense ceramic with high-temperature strength | Strength of 500-600 MPa at ~1400°C; excellent thermal conductivity | Aerospace components, mechanical seals |

| Zirconia (ZrO2) | Toughened by dopants like MgO, CaO, Y2O3 | Strength ~1200 MPa; fracture toughness ~15 MPa·m | Dental implants, thermal barrier coatings |

| Boron Carbide (B4C) | Extremely hard, one of the hardest ceramics | High wear resistance | Armor plating, abrasives |

| Titanium Diboride (TiB2) | High hardness and chemical inertness | Excellent corrosion resistance | Armor, cutting tools |

These materials combine exceptional hardness and toughness with thermal shock resistance, enabling their use in protective armor, cutting and machining tools, high-temperature engine parts, and wear-resistant components. Their performance under extreme conditions often surpasses traditional materials, contributing to longer service life and improved safety in critical applications.

Request a custom quote for advanced ceramic products.

What Are Functional Advanced Ceramics and How Do They Enhance Technology?

Functional ceramics are prized for their unique physical phenomena, which include electrical insulation, piezoelectricity, magnetism, and superconductivity. They form the core of many modern electronic, communication, and biomedical devices.

| Functional Type | Typical Materials | Key Properties | Applications |

| Electronic Insulators | Alumina (Al2O3), Aluminum Nitride (AlN) | High dielectric strength, thermal conductivity | Circuit substrates, heat sinks |

| Dielectric Materials | Barium Titanate (BaTiO3), Perovskites | High permittivity, tunable capacitance | Capacitors, RF filters |

| Piezoelectric Ceramics | Lead Zirconate Titanate (PZT), others | Electric charge generation under mechanical stress | Sensors, actuators, medical ultrasound |

| Magnetic Ceramics | Ferrites, Rare-earth magnets | Hard and soft magnetic properties | Data storage, transformers |

| Superconducting Ceramics | Yttrium Barium Copper Oxide (YBCO), others | Zero electrical resistance below critical temperatures | Power transmission, magnetic devices |

| Antibacterial Ceramics | Silver-doped materials, TiO2 photocatalysts | Microbial inhibition, sterilization | Medical devices, coatings |

These ceramics support the trend toward device miniaturization, enhanced energy efficiency, and biocompatibility. For example, piezoelectric ceramics are fundamental in sensors and medical ultrasound, while magnetic ceramics enable compact data storage and efficient transformers. Antibacterial ceramics are gaining increasing use in healthcare environments to reduce infections.

How Do Different Advanced Ceramic Materials Compare Across Properties and Applications?

A comparative understanding of advanced ceramics allows engineers and designers to optimize material selection based on specific performance requirements.

| Material | Mechanical Strength | Thermal Stability | Electrical Properties | Typical Industrial Use |

| Alumina (Al2O3) | High | Excellent | Electrical insulator | Electrical substrates, tooling |

| Zirconia (ZrO2) | Very High | High | Electrical insulator | Dental implants, cutting tools |

| Silicon Carbide (SiC) | Very High | Exceptional | Semiconductor | Aerospace, power electronics |

| Silicon Nitride (Si3N4) | High | High | Electrical insulator | Bearings, engine components |

| Barium Titanate (BaTiO3) | Moderate | Moderate | Dielectric | Capacitors, sensors |

| Lead Zirconate Titanate (PZT) | Moderate | Moderate | Piezoelectric | Ultrasound equipment, actuators |

This comparison highlights the diversity and specialization of advanced ceramics, emphasizing the critical need to match ceramic properties to the operational environment and functionality.

What Are the Production Challenges and Process Requirements for Advanced Ceramics?

Manufacturing advanced ceramics involves overcoming significant technical challenges to ensure high purity, precise microstructure, and optimal performance.

- Achieving ultra-high purity and consistent particle size distribution in powders.

- Avoiding common defects such as porosity, cracks, and inhomogeneities during sintering.

- Controlling grain growth and microstructure to optimize toughness and other properties.

- Selecting and managing sintering additives that aid densification without compromising integrity.

| Production Step | Purpose | Challenges |

| Powder Preparation | Obtain high-purity and uniform particles | Prevent contamination, control agglomeration |

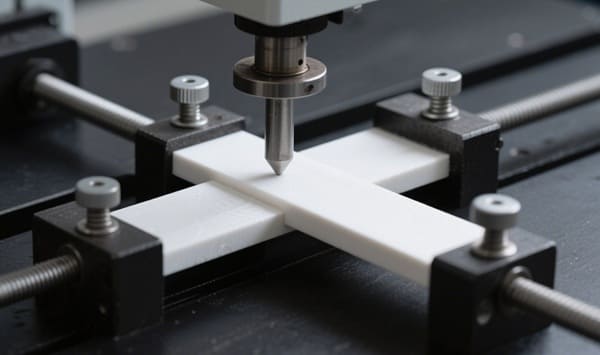

| Forming | Shape the ceramic to near-final geometry | Achieve dimensional accuracy, avoid cracks |

| Sintering | Densify material, develop microstructure | Precise temperature, atmosphere control |

| Finishing | Improve surface quality and tolerances | Avoid warping, microcracks |

The complexity and precision required during these steps explain why advanced ceramics often come at a higher cost compared to traditional ceramics.

What Are the Current Trends and Future Prospects of Advanced Ceramics?

The field of advanced ceramics is dynamic, with ongoing research focused on overcoming limitations and unlocking new functionalities.

- Development of nanostructured ceramics that exhibit improved toughness and multifunctionality.

- Adoption of additive manufacturing (3D printing) to create complex shapes and customized components.

- Design of ceramic-metal composites to combine the best of both material classes.

- Exploration of ceramics for energy harvesting and storage, including fuel cells and batteries.

- Implementation of environmentally friendly, sustainable processing techniques to reduce ecological impact.

| Sector | Emerging Application | Impact |

| Aerospace | Thermal barrier coatings | Enhanced engine efficiency |

| Electronics | Miniaturized sensors and substrates | Increased device performance |

| Biomedical | Biocompatible implants | Improved patient outcomes |

| Energy | Solid oxide fuel cells, batteries | Sustainable energy solutions |

These trends indicate that advanced ceramics will continue to be a foundational pillar in industrial innovation.

FAQ

| Question | Brief Answer |

| What makes ceramics “advanced”? | High purity, engineered microstructure, and superior properties compared to traditional ceramics. |

| What industries use advanced ceramics? | Aerospace, electronics, automotive, medical, and energy sectors. |

| How are structural and functional ceramics different? | Structural ceramics offer mechanical durability, and functional ceramics provide electronic or magnetic functionalities. |

| Are advanced ceramics expensive? | Generally yes, due to complex manufacturing processes, but costs are decreasing with new technologies. |

| Can advanced ceramics be 3D printed? | Yes, additive manufacturing is emerging as a promising method for complex ceramic parts. |

Conclusion

Advanced ceramics are transforming the industrial landscape with their unique combination of exceptional mechanical, thermal, electrical, and biological properties. Their critical role spans from aerospace components that endure extreme conditions to biocompatible implants that improve human health. As manufacturing technologies and material innovations progress, advanced ceramics will increasingly enable cutting-edge solutions, solidifying their place as indispensable materials shaping the future of multiple high-tech industries.

Looking for high-quality advanced ceramic products? Contact us today!