Beryllium Oxide (BeO) vs. Other Ceramic Materials: Key Properties and Applications

Beryllium Oxide (BeO) is one of the most extraordinary technical ceramics in existence. It offers unique combinations of thermal conductivity, electrical insulation, and mechanical stability that few materials can match. In this article, we’ll explore the full spectrum of BeO’s capabilities—from its physical and chemical properties to its distinct advantages in high-end industrial applications. You’ll also gain insight into how BeO compares with other ceramics, such as alumina, zirconia, and silicon nitride, in practical use cases. Finally, we’ll cover critical considerations like health hazards, processing requirements, and the cost-benefit analysis of choosing BeO over more common ceramics.

At Advanced Ceramic Hub, we specialize in high-quality ceramic products, ensuring optimal performance for industrial and scientific applications.

What Is Beryllium Oxide and Why Is It Unique Among Ceramics?

Technically classified as a high-performance oxide ceramic, BeO’s standout feature is its combination of near-metal-level thermal conductivity and superior electrical insulation. With a lightweight density of approximately 3.02 g/cm³, it remains structurally stable even in extreme heat, resisting thermal cycling up to around 1800 °C. Its electrical resistivity above 10¹⁴ Ω·cm ensures isolation in high-voltage applications. These properties are rare to find simultaneously in a single material. BeO’s ability to manage heat effectively while resisting electrical current makes it a unique solution in fields demanding both performance and safety.

| Property | BeO (Beryllium Oxide) |

| Thermal Conductivity | ~300 W/m·K |

| Electrical Resistivity | >10¹⁴ Ω·cm |

| Density | ~3.02 g/cm³ |

| Max Operating Temp | ~1800 °C |

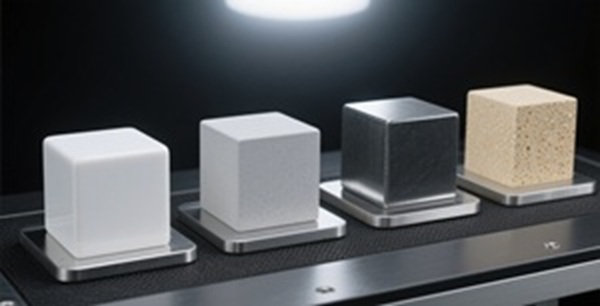

How Does BeO Compare to Other Common Ceramic Materials?

When assessing BeO, it’s essential to benchmark it against other widely used ceramics. Alumina provides cost-effective insulation but is thermally limited. Zirconia is tough but inadequate for heat management, and silicon nitride is shock resistant but not a top heat conductor. Below is a clear comparison:

| Property | BeO | Al₂O₃ | ZrO₂ | Si₃N₄ |

| Thermal Conductivity (W/m·K) | 300 | 30 | 2 | 25 |

| Electrical Resistivity | >10¹⁴ | 10¹⁴ | 10¹⁰ | 10¹² |

| Max Temp (°C) | 1800 | 1600 | 1000 | 1400 |

| Fracture Toughness | Medium | Low | High | Very High |

This comparison highlights how BeO stands apart. It’s not just a ceramic, but a hybrid material that bridges the performance of metal and ceramic. Its value shines in high-heat, high-frequency, or high-power systems where heat must be quickly conducted away without compromising electrical safety.

What Are the Key Industrial Applications of Beryllium Oxide?

BeO’s unique property matrix allows it to serve in a surprisingly wide range of technical industries. In electronics, it keeps radio-frequency (RF) devices, amplifier substrates, and laser tube insulators running cool and safe. Aerospace engineers use it in satellite components like radomes and thermal shield linings to handle temperature extremes. In nuclear applications, BeO acts as a neutron moderator and radiation shield. Even in medical tubing and X-ray housing, BeO prevents thermal and electrical failure. What ties these use cases together is the need for high thermal performance, electrical insulation, and dimensional stability.

| Industry | Typical Use Cases |

| Electronics | RF components, amplifier substrates, tube insulators |

| Aerospace | Satellite radomes, thermal shields |

| Nuclear | Neutron moderators, radiation shielding |

| Medical | High-voltage X-ray housings, tube insulation |

These roles often combine harsh environments, continuous operation, and demand for zero breakdown, exactly where BeO excels.

Why Is Beryllium Oxide Ideal for Thermal Management Applications?

Effective thermal management is crucial in high-power electronics, lasers, and RF amplifiers. BeO outperforms many options with heat conduction nearly ten times that of aluminum nitride and orders of magnitude better than alumina.

| Material | Thermal Conductivity (W/m·K) |

| BeO | 300 |

| AlN | 170 |

| Al₂O₃ | 30 |

| Silicon | 150 |

This means heat generated in a confined area travels quickly through BeO, preventing hotspots and extending device lifespan. BeO’s stability up to 1800 °C underpins its reliability in steep thermal gradients, making it the preferred choice for intensive heat-dissipation roles like thermal interface materials and high-power module bases.

Explore our high-quality ceramic products.

What Are the Health and Handling Concerns of BeO?

Despite its attractive engineering properties, BeO poses serious health risks if inhaled. Chronic exposure to beryllium oxide dust can lead to berylliosis, a potentially debilitating lung condition. Therefore, production environments must enforce strict prevention protocols.

| Risk | Recommended Safety Measures |

| Inhalation of dust | Use HEPA-filter ventilation and full PPE |

| Machining | Use wet diamond tools or seal grinders inside enclosures |

| Waste Disposal | Follow hazardous material regulations |

Once embedded in machinery or electronic assemblies, BeO is inert. The primary concern lies in manufacturing and machining areas requiring sealed conditions and monitoring.

How Does BeO Perform in High-Frequency Dielectric Applications?

BeO’s usefulness extends beyond thermal systems into the realm of high-frequency electronics. It maintains consistent electrical behavior even in gigahertz ranges.

| Property | BeO | Al₂O₃ | Quartz |

| Dielectric Constant | ~6.5 | ~9.8 | ~3.8 |

| Loss Tangent | <0.001 | ~0.0002 | ~0.0002 |

| Magnetic Permeability | ~1.0 | ~1.0 | ~1.0 |

Compared with alumina, BeO offers lower dielectric loss while maintaining moderate permittivity—ideal for microwave ovens, radar antennas, and RF power modules. Its consistent loss tangent across frequencies ensures signal fidelity in sensitive applications.

What Are the Advantages and Limitations of BeO?

Now that we’ve examined properties and applications, let’s weigh BeO’s strengths against its practical drawbacks.

| Advantages | Limitations |

| ✅ Exceptional thermal conductivity | ⚠ Toxic dust—requires containment |

| ✅ High electrical insulation | ⚠ High cost and complex processing |

| ✅ High-temperature stability | ⚠ Uses wet machining—adds steps and time |

In mission-critical equipment, BeO’s performance can justify the expense and precautions. However, for routine parts, alumina or aluminum nitride may offer sufficient properties at a lower cost.

How Is BeO Processed Compared to Other Ceramics?

Producing BeO parts requires specialized equipment and protocols. It’s powder compacts via cold isostatic pressing, then sintered at ~1800 °C. Wet machining or diamond-based CNC must follow strict environmental controls.

| Production Step | BeO | Other Ceramics |

| Forming | Cold isostatic pressing | Dry press/injection molding |

| High-temp Sintering | ~1800 °C | 1400–1600 °C |

| Machining | Wet + diamond CNC | Dry CNC with PCD or HSS |

While other ceramics may allow workshop milling, BeO demands sealed environments and water-based coolants, contributing to higher manufacturing costs.

Request a custom quote for various ceramic products.

FAQ

| Question | Is BeO electrically stable at high frequency? |

| Is BeO safe in sealed devices? | Yes—ingestion hazards only arise during manufacture |

| Can BeO be CNC machined? | Yes, but only with wet diamond tooling for safety |

| Is BeO better than Al₂O₃ for heat sinks? | Absolutely—about 10× better thermal performance |

| Is BeO electrically stable at high freq? | Yes—low loss and stable permittivity across RF/microwave |

| Can BeO be used with magnets? | No, but it’s an effective insulator in magnet assemblies |

These FAQs provide quick guidance on design, safety, and material decisions.

Conclusion

Beryllium Oxide is where metal-like thermal performance meets ceramic insulation resilience. Its remarkable thermal and dielectric capabilities are unmatched, making it indispensable for advanced applications across aerospace, electronics, medical, and nuclear industries. However, this performance comes with higher cost, complexity, and safety requirements. For mission-critical systems demanding exceptional heat removal and electrical isolation, BeO remains the material of choice—capable of supporting the most extreme operating conditions other ceramics simply cannot endure.

Looking for high-quality ceramic products? Contact us today!