Why Beryllium Oxide (BeO) Is the Top Choice for High-Performance Heat Dissipation

In the world of high-performance technologies, effective heat dissipation is essential to ensure optimal functioning and longevity of systems, from electronics to aerospace applications. Traditional materials like copper and aluminum have long been used for heat management, but as devices become more powerful, the demand for better materials has grown. Beryllium Oxide (BeO) has emerged as the top choice for heat dissipation due to its unique combination of high thermal conductivity, excellent electrical insulation, and remarkable mechanical strength. This article explores why BeO is considered the gold standard in high-performance heat dissipation and its advantages over other materials.

At Advanced Ceramics Hub, we specialize in high-quality ceramic products made from a variety of materials and specifications, ensuring optimal performance for industrial and scientific applications.

What is Beryllium Oxide (BeO)?

Beryllium Oxide (BeO), also known as beryllia, is a ceramic material renowned for its exceptional thermal and electrical properties. Unlike traditional ceramics, BeO combines high thermal conductivity with excellent electrical insulation, making it a standout choice for applications requiring efficient heat dissipation. Its unique crystalline structure allows it to transfer heat rapidly while maintaining structural integrity under extreme conditions. Historically, BeO has been utilized in industries such as aerospace, electronics, and telecommunications, where managing heat in compact, high-performance systems is critical.

The material’s adoption began in the mid-20th century, particularly in military and aerospace applications, due to its ability to withstand high temperatures and harsh environments. Today, BeO is a cornerstone in advanced electronics, where miniaturization and increased power densities demand superior thermal management. Its versatility has made it indispensable in cutting-edge technologies, from satellite systems to high-power RF devices.

| Property | Value | Unit | Remarks |

| Chemical Formula | BeO | – | Inorganic compound |

| Molecular Weight | 25.01 | g/mol | – |

| Density | 3.01 | g/cm³ | High density for a ceramic |

| Melting Point | 2,570 | °C | Extremely refractory |

| Thermal Conductivity | 250–330 | W/m·K (at 25°C) | Among the highest for an electrical insulator (higher than AlN & Al₂O₃) |

| Coefficient of Thermal Expansion (CTE) | 6.0–8.5 (20–1000°C) | ×10⁻⁶/°C | Matches well with semiconductors (e.g., Si, GaAs) |

| Dielectric Constant (ε) | 6.5–7.0 (at 1 MHz) | – | Low dielectric loss, suitable for RF/microwave applications |

| Dielectric Strength | 10–15 | kV/mm | High electrical insulation |

| Volume Resistivity | >10¹⁴ | Ω·cm | Excellent insulator at room temperature |

| Hardness (Mohs) | ~9 | – | Comparable to alumina (very hard) |

| Flexural Strength | 170–230 | MPa | Mechanically robust |

| Young’s Modulus | 300–400 | GPa | High stiffness |

| Poisson’s Ratio | 0.25–0.30 | – | Typical for ceramics |

| Solubility in Water | Insoluble | – | Chemically stable |

| Toxicity | Highly toxic (inhalation hazard) | – | Causes chronic beryllium disease (CBD); requires strict safety measures |

Notes:

- Thermal Conductivity: Exceeds most ceramics (e.g., Al₂O₃: ~30 W/m·K; AlN: ~180 W/m·K).

- CTE: Closely matches silicon (Si: ~4.2×10⁻⁶/°C), reducing thermal stress in electronics.

- Dielectric Properties: Ideal for high-frequency circuits (e.g., 5G, radar).

- Toxicity: OSHA and IARC classify BeO as a Category 1 carcinogen (requires PPE like respirators and gloves).

Looking for top-quality ceramic products? Explore Advanced Ceramics Hub’s selection.

Exceptional Thermal Conductivity of Beryllium Oxide (BeO)

BeO’s thermal conductivity, ranging from 250 to 300 W/m·K, is among the highest of any ceramic material, surpassed only by diamond in some cases. This property allows BeO to efficiently transfer heat away from critical components, preventing overheating in high-performance systems. For comparison, common ceramics like alumina (Al₂O₃) have thermal conductivities of around 20–30 W/m·K, making BeO up to ten times more effective at heat dissipation. This capability is particularly valuable in applications where heat buildup can degrade performance or cause system failure.

In practical terms, BeO’s high thermal conductivity enables faster heat dissipation in compact electronic devices, such as power amplifiers and microprocessors. This ensures stable operation under high power loads, extending the lifespan of components. Additionally, BeO’s ability to maintain its thermal performance across a wide temperature range makes it ideal for extreme environments, such as space or high-altitude applications.

Thermal Conductivity of Beryllium Oxide (BeO) vs. Other Materials

| Material | Thermal Conductivity (W/m·K @ 25°C) | Electrical Insulation? | Key Applications |

| Beryllium Oxide (BeO) | 250–330 | ✅ (Excellent) | High-power electronics, RF, nuclear |

| Aluminum Nitride (AlN) | ~170–220 | ✅ | LED substrates, power modules |

| Silicon Carbide (SiC) | 120–200 | ❌ (Semiconductor) | High-temp electronics, EV power devices |

| Alumina (Al₂O₃) | 20–30 | ✅ | Insulators, substrates |

| Copper (Cu) | ~400 | ❌ (Conductive) | Heat sinks, electrical wiring |

| Diamond | 900–2,300 | ❌ (Depends on doping) | Extreme thermal management |

Why Is Beryllium Oxide’s Thermal Conductivity So High?

BeO’s exceptional heat transfer stems from:

- Strong covalent Be-O bonds (short bond length → efficient phonon transport).

- Simple crystal structure (hexagonal wurtzite, similar to AlN but with lighter atoms).

- Low phonon scattering (fewer lattice defects → better heat conduction).

Temperature Dependence:

- BeO retains >100 W/m·K even at 1,000°C, unlike metals (e.g., copper drops sharply with temperature).

Explore our optimized ceramic products.

High Electrical Insulation Properties of Beryllium Oxide (BeO)

One of BeO’s standout features is its ability to combine high thermal conductivity with excellent electrical insulation. With a dielectric strength of approximately 20 kV/mm, BeO can effectively isolate electrical currents while efficiently dissipating heat. This dual functionality is critical in applications like RF transistors and power electronics, where components must manage heat without compromising electrical performance.

For example, in high-frequency circuits, BeO substrates prevent unwanted electrical interference while ensuring heat from active components is rapidly dissipated. This makes BeO a preferred material in telecommunications and radar systems, where both thermal and electrical performance are non-negotiable. Its insulation properties also reduce the risk of short circuits, enhancing system reliability.

1. Key Electrical Properties of Beryllium Oxide (BeO)

| Property | Value | Unit | Significance |

| Volume Resistivity | >10¹⁴ (at 25°C) | Ω·cm | Extremely high insulation, even at elevated temperatures |

| Dielectric Constant (ε) | 6.5–7.0 (at 1 MHz) | – | Low signal loss, ideal for RF/microwave circuits |

| Dielectric Strength | 10–15 | kV/mm | Withstands high voltages before breakdown |

| Dissipation Factor (tan δ) | 0.0001–0.0004 (at 1 MHz) | – | Minimal energy loss at high frequencies |

| Band Gap | ~10.6 eV | eV | Large band gap → excellent insulator |

2. Comparison with Other Insulating Ceramics

| Material | Volume Resistivity (Ω·cm) | Dielectric Constant (ε) | Dielectric Strength (kV/mm) |

| BeO | >10¹⁴ | 6.5–7.0 | 10–15 |

| Al₂O₃ | >10¹³ | ~9.0–10.0 | 8–12 |

| AlN | >10¹³ | ~8.5–9.5 | 14–17 |

| Si₃N₄ | >10¹² | ~7.0–8.5 | 15–20 |

3. Why Is Beryllium Oxide (BeO) Such a Good Electrical Insulator?

- Wide Band Gap (10.6 eV): Prevents electron excitation, ensuring minimal conductivity.

- High Purity & Dense Structure: Minimizes defects that could cause current leakage.

- Stable at High Temperatures: Maintains insulation even near 1000°C, unlike polymers or some oxides.

4. Benefits of Beryllium Oxide’s Electrical Insulation

- Prevents electrical leakage in high-voltage applications.

- Supports compact designs by combining thermal and electrical functions.

- Enhances reliability in sensitive electronic systems.

Discover our high-quality ceramic material products.

Mechanical Strength and Durability of Beryllium Oxide (BeO)

BeO is not only thermally and electrically superior but also mechanically robust. Its high hardness (Mohs scale ~9) and resistance to thermal shock make it suitable for demanding environments. Unlike many ceramics that crack under rapid temperature changes, BeO’s low thermal expansion coefficient ensures it remains stable, even in extreme conditions like those encountered in aerospace or high-power electronics.

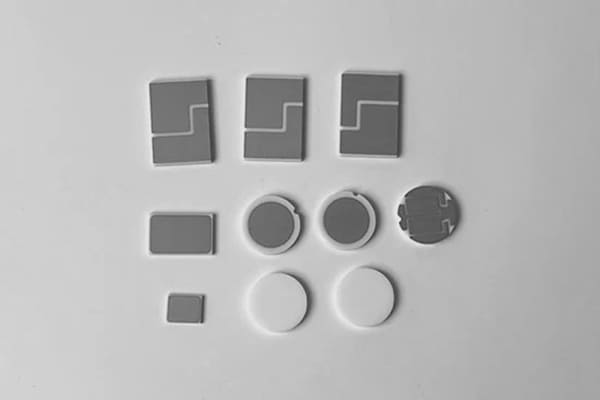

This durability translates to longer lifespans for components using BeO substrates or heat sinks. For instance, in satellite systems, BeO’s ability to withstand thermal cycling and mechanical stress ensures consistent performance over extended missions. Its strength also allows it to be machined into precise shapes, enabling customized thermal management solutions.

1. Key Mechanical Properties of Beryllium Oxide (BeO)

| Property | Value | Unit | Significance |

| Flexural Strength | 170–230 | MPa | Comparable to Al₂O₃, suitable for structural components |

| Compressive Strength | 800–1,000 | MPa | Withstands high-pressure environments |

| Young’s Modulus (Elastic Modulus) | 300–400 | GPa | High stiffness, resists deformation |

| Hardness (Mohs Scale) | ~9 | – | Similar to alumina (very hard, scratch-resistant) |

| Fracture Toughness (KIC) | 2.5–3.5 | MPa·m1/2 | Moderate crack resistance (lower than Si₃N₄/ZrO₂) |

| Poisson’s Ratio | 0.25–0.30 | – | Standard for ceramics |

| Density | 3.01 | g/cm³ | Lighter than tungsten carbide (15.6 g/cm³) |

2. Comparison with Other Structural Ceramics

| Material | Flexural Strength (MPa) | Hardness (Mohs) | Fracture Toughness (MPa·m1/2) | Young’s Modulus (GPa) |

| BeO | 170–230 | ~9 | 2.5–3.5 | 300–400 |

| Al₂O₃ (99%) | 300–400 | 9 | 3.5–4.5 | 300–400 |

| AlN | 300–350 | ~8 | 2.5–3.0 | 310–330 |

| Si₃N₄ | 600–1,200 | ~9 | 6.0–8.0 | 300–320 |

| ZrO₂ (Y-TZP) | 900–1,400 | 8.5 | 7.0–10.0 | 200–210 |

3. Why Is Beryllium Oxide (BeO) Mechanically Strong Yet Brittle?

- Covalent Bonding: Strong Be-O bonds contribute to hardness but limit plasticity.

- Hexagonal Crystal Structure: Provides rigidity but lacks slip systems for ductility.

- Grain Boundary Effects: Pure BeO has minimal grain boundary impurities, enhancing strength but reducing crack resistance.

Lightweight and Compact Design

The lightweight nature of Beryllium Oxide is another reason it is preferred for high-performance heat dissipation. BeO’s low density ensures that systems using it remain light, which is a major benefit for applications where weight and size are critical. For instance, aerospace technology and mobile devices, where every gram matters, benefit greatly from BeO’s properties.

In addition to being lightweight, BeO can be molded into compact shapes, making it suitable for tight spaces in advanced technology applications. This flexibility allows engineers to design more efficient and space-saving thermal management solutions.

Applications of Beryllium Oxide (BeO) in Electronics and Semiconductors

BeO is widely used in electronics and semiconductors due to its ability to manage heat in high-power, compact devices. In power amplifiers, for instance, BeO substrates dissipate heat generated during signal amplification, preventing performance degradation. Similarly, in LEDs, BeO heat sinks ensure consistent light output by maintaining optimal operating temperatures. Microprocessors, which generate significant heat during operation, also benefit from BeO’s thermal efficiency.

The rise of 5G technology has further increased BeO’s relevance, as high-frequency RF components require robust thermal management to maintain signal integrity. By enabling smaller, more efficient designs, BeO supports the trend toward miniaturization in consumer electronics and telecommunications.

Key Semiconductor & Electronics Applications

A. High-Power Devices

RF/Microwave Transistors

- Use Case: 5G base stations, radar systems

- BeO Role: Substrates for GaN/SiC devices dissipate 100+ W/cm² heat.

- Example: Northrop Grumman’s AESA radars use BeO-packed amplifiers.

IGBT & Thyristor Modules

- Use Case: EV inverters, industrial motor drives

- BeO Role: Insulating spacers between Si chips and copper baseplates.

B. Optoelectronics

Laser Diode Mounts

- Use Case: Fiber optics, lidar

- BeO Role: Coefficient of Thermal Expansion (CTE) matches GaAs/AlGaAs lasers → prevents misalignment.

C. Advanced Packaging

Multi-Chip Modules (MCMs)

- Use Case: Aerospace avionics

- BeO Role: Interposers with embedded microchannels for 3D IC cooling.

Vacuum Electron Devices

- Use Case: Satellite comms tubes

- BeO Role: High-voltage insulators in TWTs (Traveling Wave Tubes).

Request a custom quote for high-quality ceramic products.

Environmental Considerations and Safety

While BeO offers unmatched performance, its toxicity requires careful handling. Beryllium compounds, when inhaled as dust or fumes, can cause serious health issues, including chronic beryllium disease. To mitigate risks, manufacturers employ strict safety protocols, such as using sealed environments during processing and ensuring proper ventilation. End-users, however, typically face minimal risk, as BeO is safe in its solid, finished form.

Proper disposal and recycling of BeO components are also critical to prevent environmental contamination. Regulatory guidelines, such as those from OSHA and EPA, outline safe practices for handling BeO. By adhering to these standards, industries can safely leverage BeO’s benefits without compromising worker or environmental safety.

1. Health Hazards of BeO Exposure

Primary Risks

| Exposure Route | Health Impact | OSHA Permissible Exposure Limit (PEL) |

| Inhalation (Dust/Fumes) | Chronic Beryllium Disease (CBD), lung cancer | 0.2 µg/m³ (8-hr avg) |

| Skin Contact | Dermatitis, ulcers (if particles embed) | – |

| Ingestion | Low absorption, but chronic exposure harms organs | – |

- Chronic Beryllium Disease (CBD): Immune-mediated lung disorder (incurable, similar to silicosis).

- Carcinogenicity: IARC classifies BeO as Group 1 (human carcinogen).

At-Risk Groups

- Workers in machining, sintering, or recycling BeO ceramics.

- Electronics assemblers handling unencapsulated BeO substrates.

2. Regulatory Framework

| Region | Regulation | Key Requirement |

| USA | OSHA 29 CFR 1910.1024 | Mandates exposure monitoring, medical surveillance, and PPE. |

| EU | REACH Annex XVII | Restricts BeO use; requires authorization for industrial applications. |

| China | GBZ 2.1-2019 | Sets workplace exposure limits (0.1 µg/m³, stricter than OSHA). |

Industry Standards:

- IPC-1601: Guidelines for BeO handling in PCB manufacturing.

- DOE 10 CFR 850: Beryllium safety rules for nuclear facilities.

3. Safety Measures for BeO Handling

Engineering Controls

- Closed Processing: Use glove boxes/HEPA-filtered enclosures for machining.

- Wet Machining: Minimizes airborne dust during cutting/grinding.

- Negative Pressure Labs: Prevents particulate leakage in R&D facilities.

Personal Protective Equipment (PPE)

| Scenario | Required PPE |

| Machining | Powered air-purifying respirator (PAPR), Tyvek suits |

| Cleanroom Assembly | N95 masks, nitrile gloves |

| Emergency Spill Cleanup | Full-face respirator, chemical-resistant coveralls |

Waste Disposal

- Solid Waste: Seal in polyethylene bags labeled “Beryllium-Containing Material.”

- Liquid Waste: pH adjustment to precipitate Be²⁺ ions before filtration.

- Recycling: Only via licensed facilities (e.g., Brush Wellman’s beryllium reclamation program).

4. Environmental Impact

Lifecycle Risks

| Stage | Potential Hazard | Mitigation |

| Mining | Soil/water contamination from beryl ore extraction | Acid mine drainage treatment |

| Manufacturing | Airborne BeO emissions | Scrubbers, electrostatic precipitators |

| End-of-Life | Landfill leaching | Encapsulation in epoxy/glass before disposal |

At Advanced Ceramics Hub, we supply optimized-grade ceramic products that comply with ASTM and ISO standards, ensuring outstanding quality and reliability.

Research into Beryllium Oxide is ongoing, and future developments could lead to even more efficient heat dissipation solutions. Innovations may include improving the material’s thermal conductivity or enhancing its environmental and safety properties.

The future also holds potential for BeO in emerging technologies such as quantum computing, where high-performance materials are required to manage heat dissipation effectively. The continuing refinement of BeO’s manufacturing processes could make it even more versatile, expanding its use in more industries.

For top-quality ceramic products, Advanced Ceramics Hub provides tailored solutions and precision machining techniques for various applications.

Looking for premium ceramic products? Contact us today!