Lanthanum Hexaboride Cathode

Lanthanum Hexaboride Cathode

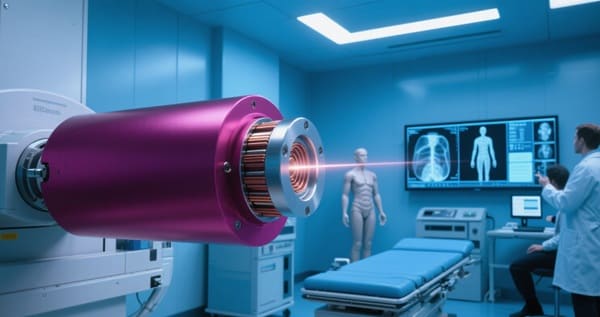

Lanthanum hexaboride cathode is a high-performance electron emission source widely used in scientific and industrial vacuum systems. Known for its low work function, high current density, and excellent thermal stability, this cathode material enables reliable operation in applications such as electron microscopes, X-ray sources, and ion beam equipment. Its long service life and resistance to contamination make it an ideal choice for environments requiring steady, high-intensity electron output. We can supply high-quality Lanthanum Hexaboride Cathode with various specifications and competitive prices, offering customized solutions to meet specific requirements.

Or email us at sales@heegermaterials.com.Lanthanum Hexaboride Cathode Data Sheet

| Color: | Purple |

| Chemical Formula: | LaB6 |

| Dimension Range: | customized |

| Length Range: | customized |

Lanthanum Hexaboride Cathode Description

Lanthanum hexaboride cathode is renowned for its outstanding electron emission efficiency and exceptional thermal resilience, making it indispensable in many high-vacuum electronic devices. This cathode material exhibits a low work function, which allows for high electron emission at relatively lower temperatures compared to traditional tungsten cathodes. Its robust performance in extreme conditions, including high temperatures and corrosive environments, ensures long operational lifespans and reduces the frequency of replacement. Widely used in electron microscopes, X-ray tubes, plasma sources, and ion implantation equipment, lanthanum hexaboride cathodes provide stable and consistent electron beams crucial for precision applications.

Lanthanum Hexaboride Cathode Chemical Compositions

| LaB6 Purity: 99%, 99.9%, 99.9995%, B(% min.): 31% | |||

| Rare Earth Impurities | Non-RE Impurities | ||

| Ce | <120ppm | Fe | <250ppm |

| Pr | <150ppm | Si | <100ppm |

| Nd | <180ppm | Ca | <90ppm |

| Sm | <112ppm | C | <300ppm |

| Y | <250ppm | Mg | <100ppm |

| Ti | <100ppm | ||

Lanthanum Hexaboride Cathode Features

- High Electron Emission Efficiency: Lanthanum hexaboride cathode features a low work function (~2.4 eV), enabling stable and efficient electron emission at lower temperatures than traditional cathodes.

- Excellent Thermal Stability: The lanthanum hexaboride cathode can operate continuously at temperatures above 1800 °C, ensuring durability in high-temperature vacuum environments.

- Long Service Life: The lanthanum hexaboride cathode has a low evaporation rate and strong resistance to contamination, maintaining performance over extended periods and reducing replacement frequency.

- Superior Chemical Resistance: Lanthanum hexaboride cathode resists oxidation and corrosion in harsh vacuum and reactive gas conditions, preserving structural integrity and emission stability.

- Consistent Electrical Conductivity: Lanthanum hexaboride cathode provides reliable and stable current flow critical for precision electron beam and plasma generation applications.

Lanthanum Hexaboride Cathode Applications

- Electron Microscopes: Lanthanum hexaboride cathode is widely used in scanning electron microscopes (SEM) and transmission electron microscopes (TEM) for consistent electron emission that improves imaging resolution.

- X-ray Tubes: Lanthanum hexaboride cathode acts as a reliable electron source in X-ray generation for medical imaging, material analysis, and security inspection.

- Plasma Generators: Lanthanum hexaboride cathode supports high-density electron beams needed in plasma generators for industrial processing and scientific research.

- Ion Implantation Equipment: lanthanum hexaboride cathode ensures efficient ion source operation in semiconductor manufacturing and surface treatment technologies.

- Vacuum Tubes and Electron Guns: Lanthanum hexaboride cathode is essential in devices requiring precise, high-current electron beams, such as electron beam welders, lithography systems, and particle accelerators.

Lanthanum Hexaboride Ceramic Properties

Lanthanum Hexaboride Ceramic Material Machining

Lanthanum Hexaboride (LaB6) Ceramic is a specialized material prized for its excellent thermionic emission, high melting point, and chemical stability. These properties make it essential in electron emission applications but also pose challenges in machining due to its hardness and brittleness. Key machining considerations include:

- Cutting: Precision diamond-coated tools or laser cutting methods are necessary to achieve clean edges while preventing microcracks and surface damage.

- Grinding: Fine diamond grinding wheels provide the accuracy needed to maintain dimensional tolerances and surface smoothness, particularly for intricate or small components.

- Drilling: Ultrasonic or abrasive waterjet machining techniques are often used to create precise holes and features without inducing thermal stress or cracking.

- Surface Finishing: Polishing processes improve surface quality, reduce electron scattering, and enhance emission efficiency, which is critical for high-performance cathode applications.

Lanthanum Hexaboride Ceramic Packaging

Lanthanum hexaboride ceramic products are typically packaged in vacuum-sealed bags to prevent moisture or contamination and wrapped with foam to cushion vibrations and impacts during transport, ensuring the quality of products in their original condition.

Download

Get A Quote

We will check and get back to you in 24 hours.