How to Optimize Particle Size in Ceramic Powder Preparation for Manufacturing of Ceramics

In ceramic manufacturing, particle size influences nearly every property of the final product—from densification and sintering behavior to surface finish and mechanical performance. Understanding how to control and refine ceramic powder particle size is essential for producing high-performance ceramics used in electronics, magnetics, structural parts, and coatings. This article explores the full process of particle size optimization within the broader context of the manufacturing of ceramics. As the demand for advanced ceramics increases, precision in powder preparation becomes even more critical. The goal is not just control but the ability to fine-tune ceramic functionality at the microscopic level.

At Advanced Ceramic Hub, we specialize in high-quality ceramic powder products, ensuring optimal performance for industrial and scientific applications.

What Is Ceramic Powder and How Is It Used in the Manufacturing of Ceramics?

Ceramic powders are fine, solid materials used as the starting point for fabricating technical ceramics. Their properties—especially particle size and distribution—directly affect the manufacturability and quality of ceramic components.

| Property | Impact on Ceramic Manufacturing |

| Average Particle Size | Affects sintering temperature and density |

| Surface Area | Influences reaction rate and shrinkage |

| Agglomeration | Causes defects or voids in final products |

Fine-tuning these parameters ensures consistency, reliability, and performance across ceramic applications. Manufacturers must understand how these parameters interact to ensure stable production outcomes. The choice of powder isn’t trivial—it defines the efficiency of the entire ceramic forming process.

Explore our high-quality ceramic powder product.

How Does Particle Size Influence the Manufacturing of Ceramics?

Particle size plays a major role in powder flowability, compaction, sintering behavior, and final density. Finer powders typically lead to better sintering but are harder to process.

Key effects of particle size:

- Smaller particles reduce sintering temperature.

- Uniform size improves packing density.

- Irregular size distribution may cause defects or warping.

Optimizing particle size helps strike a balance between processability and final performance. It’s a balance between what’s technically ideal and what’s economically feasible. Engineers often iterate sizing parameters multiple times to meet functional targets.

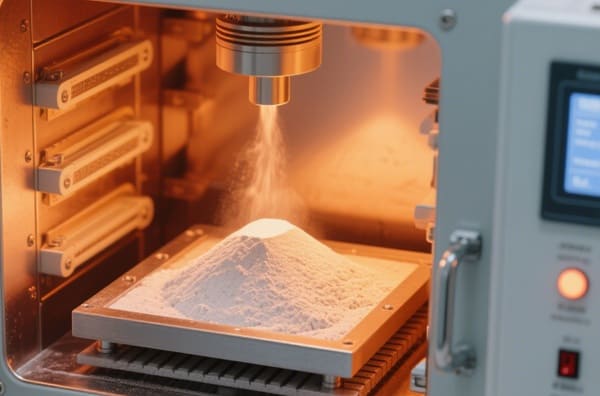

What Are the Common Methods for Controlling Particle Size in Ceramic Powders?

Manufacturers use several mechanical and chemical processes to modify particle size. The chosen method depends on the material, desired size range, and end-use application.

| Method | Description | Typical Size Range |

| Ball Milling | Mechanical grinding using media | 1–100 µm |

| Jet Milling | High-speed particle collision | 0.1–10 µm |

| Sol-Gel Processing | Chemical formation from solution precursors | <1 µm |

| Spray Drying | Forms spherical granules from suspensions | 10–200 µm |

Each method affects powder morphology and downstream ceramic properties. Engineers must weigh cost, throughput, and powder quality when choosing the right process. Selection often depends on downstream applications such as magnetics, optics, or biomedical ceramics.

Why Is Particle Size Distribution (PSD) as Important as Average Size?

A narrow PSD allows better packing and less shrinkage variation during sintering. Broad distributions may improve flowability but often reduce uniformity in the final product.

Comparing PSD Types:

- Narrow PSD: Better densification, fewer pores

- Broad PSD: Improved flow but higher risk of defects

- Bimodal PSD: Sometimes used to balance flow and packing

Understanding PSD behavior helps engineers fine-tune the microstructure of the ceramic. Adjusting PSD lets manufacturers control shrinkage gradients and mitigate crack formation. This control is vital in large-scale and high-precision ceramic parts.

What Techniques Are Used to Measure and Monitor Particle Size?

Accurate particle size analysis is vital during ceramic powder production. Common techniques include laser diffraction, image analysis, and dynamic light scattering (DLS).

| Technique | Advantages | Limitations |

| Laser Diffraction | Fast and accurate for wide ranges | Assumes spherical shape |

| SEM/Image Analysis | Direct visual confirmation | Time-consuming, manual |

| DLS (for nanoscale) | Ideal for submicron particles | Sensitive to agglomeration |

Choosing the right tool ensures precise quality control in ceramic production. These measurements are critical checkpoints in every manufacturing batch. Implementing automated feedback loops based on particle size data is also becoming more common.

How Does Particle Size Optimization Improve Magnetic Ceramic Applications?

Magnetic ceramics such as ferrites or multiferroics require tightly controlled microstructures to ensure electromagnetic performance. Particle size influences sintering density, grain boundary behavior, and permeability.

Benefits of optimized powder for magnetic ceramics:

- Reduced magnetic losses

- Higher magnetic permeability

- Improved frequency stability

Tailoring particle size enables better control over magnetic domain formation. Proper sizing not only enhances performance but also extends product lifespan. In magnetic sensor and shielding applications, the role of particle size is even more pronounced.

How Does Particle Size Optimization Compare to Other Ceramic Control Strategies?

While additives, firing conditions, and binder chemistry also affect ceramic quality, particle size has a direct impact from start to finish.

| Strategy | Control Point | Primary Impact |

| Particle Size Optimization | Powder Preparation | Sintering, density, uniformity |

| Additive Engineering | Formulation | Grain growth, porosity |

| Sintering Profile Design | Thermal Processing | Phase stability, shrinkage |

Incorporating particle size control with other strategies yields the best results in the manufacturing of ceramics. When all variables are aligned, manufacturers can achieve materials with near-theoretical density and superior performance.

How Do Different Types of Ceramic Powders Compare in the Manufacturing of Ceramics?

In the manufacturing of ceramics, the type of ceramic powder used—alumina, zirconia, silicon nitride, etc.—plays a critical role in determining not only particle size strategies but also performance, sintering behavior, and end-use suitability. Different materials require different particle size ranges and morphology control methods to optimize strength, thermal resistance, or magnetic response. Comparing their physical characteristics helps guide material selection and size optimization processes.

| Ceramic Powder Type | Typical Particle Size | Primary Properties | Manufacturing Considerations |

| Alumina (Al₂O₃) | 0.2–10 µm | Hardness, wear resistance, electrical insulation | Easy to process; suitable for structural ceramics |

| Zirconia (ZrO₂) | 0.3–5 µm | High fracture toughness, thermal insulation | Requires stabilization and controlled sintering |

| Silicon Nitride (Si₃N₄) | 0.5–2 µm | Excellent thermal shock and mechanical strength | Needs careful control of oxygen during processing |

| Magnetic Ferrites | 0.5–1 µm | Soft magnetism, low eddy current loss | Sensitive to grain boundary conditions |

| Barium Titanate (BaTiO₃) | 0.1–2 µm | High dielectric constant, piezoelectric behavior | Narrow PSD needed for capacitor-grade ceramics |

Selecting the right ceramic powder type—and optimizing its particle size accordingly—ensures the desired performance in applications ranging from magnetic devices to structural parts. The synergy between powder type and particle engineering defines success in advanced ceramic development.

Request a custom quote for ceramic powder products.

FAQ

| Question | Answer |

| Why is smaller particle size better for ceramic sintering? | Smaller particles have higher surface area, promoting faster and lower-temperature sintering. |

| Can particle size affect magnetic performance in ceramics? | Yes, especially in ferrites—grain size influences domain wall movement and permeability. |

| Is there a universal “ideal” particle size for ceramics? | No, it depends on the application, material type, and processing method. |

| How can I prevent agglomeration in fine ceramic powders? | Use dispersants, control pH, and apply gentle drying or spray drying techniques. |

| Do nano-ceramic powders require different processing steps? | Yes, they often need advanced dispersion, binder control, and specialized sintering profiles. |

These questions highlight the complexity and importance of particle size optimization in ceramic engineering. Addressing them helps guide more informed production decisions. Continuous R&D efforts are also expanding the best practices in this area.

Conclusion

In the manufacturing of ceramics, particle size isn’t just a technical parameter—it’s a design variable that impacts processing efficiency, mechanical strength, and functional performance. From magnetic applications to structural components, the ability to engineer and control powder size leads to consistent, reliable, and high-performance ceramic products. As ceramic technologies advance, particle size optimization will remain a fundamental tool for materials innovation. This knowledge enables a competitive edge and supports the creation of next-generation ceramic systems.

Looking for high-quality ceramic powder products? Contact us today!