Silicon Carbide Foam Filter

Silicon Carbide Foam Filter

Porosity: 80%-90%

Cell Size: 7-45 PPI

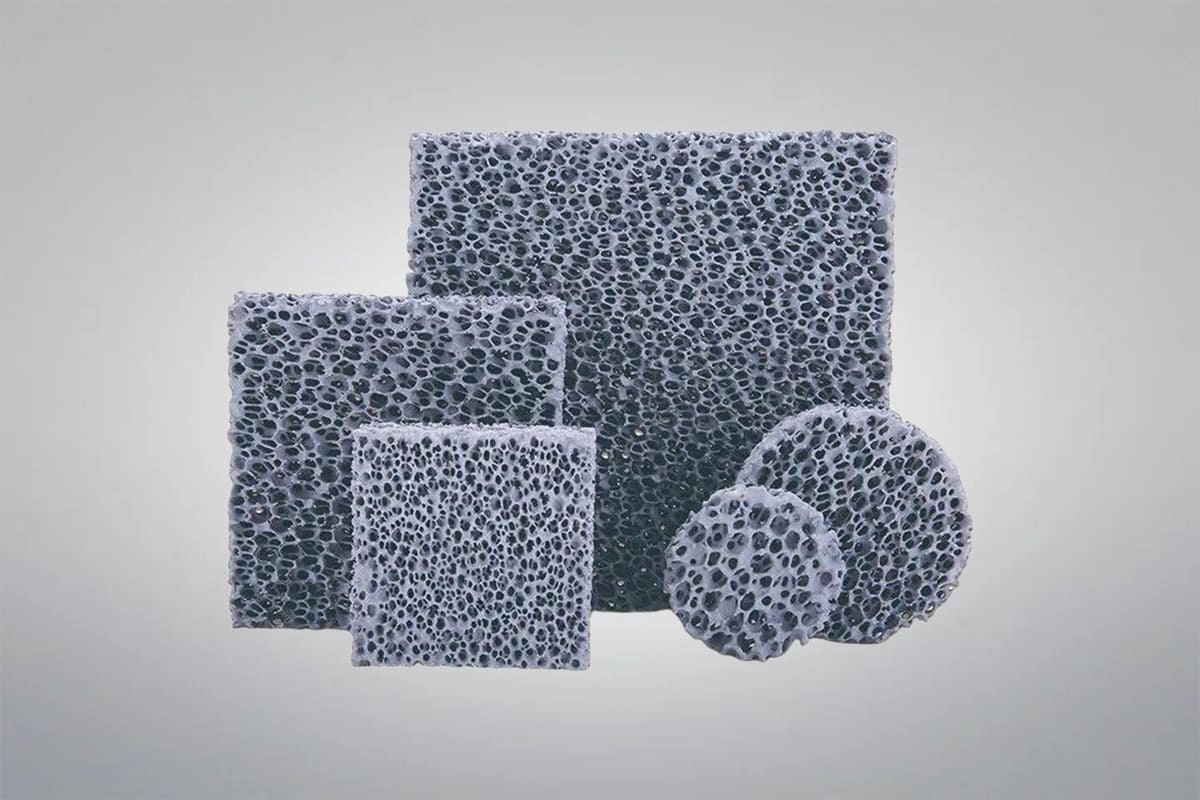

Silicon Carbide Foam Filter is a high-performance filtration material with excellent high-temperature resistance (up to 1500℃), chemical corrosion resistance, and high mechanical strength. It is widely used in metal casting, chemical, and environmental fields. As a leading supplier and manufacturer of premium silicon carbide products, we can supply high-quality silicon carbide foam filters with various specifications and competitive prices, offering customized solutions to meet specific requirements.

Or email us at sales@heegermaterials.com.Silicon Carbide Foam Filter Data Sheet

| Reference Code: | HM3012 |

| Chemical Composition: | SiC, Al2O3, SiO2 |

| Porosity: | 80%-90% |

| Pore Size: | 7-45 PPI |

| Operating Temperature: | ≤1500℃ |

| Volume Density: | 0.4-0.5 g/cm3 |

| Room Temperature Bending Strength: | 0.8 MPa |

| Room Temperature Compression Strength: | 1.0 MPa |

| Thermal Shock Resistance: | 1100℃ to room temperature, 6 times |

Silicon Carbide Foam Filter Description

Silicon Carbide Foam Filter is an effective molten metal filter with a unique porous structure, effectively removing impurities and gases from molten metal and improving the casting quality. It offers excellent high-temperature resistance (up to 1500℃), chemical resistance, and high mechanical strength, making it ideal for filtering aluminum, copper, iron, etc. The common porosities are 10 PPI, 20 PPI, 30 PPI, and 40 PPI. Advanced Ceramics Hub supports customized solutions in sizes, thicknesses, and pore sizes for diverse industry and research applications.

Silicon Carbide Foam Filter Specifications

| Dimensions (mm) | Area (mm²) | Porosity Rate (10/15ppi) | Porosity Rate (20ppi) | Porosity Rate (30ppi) | |

| Length×Width×Thickness | 40×40×11, 13, 15, 22 | 1600 | ✓ | ✓ | ✓ |

| 50×50×11, 13, 15, 22 | 2500 | ✓ | ✓ | ||

| 50×75×13, 15, 22 | 3750 | ✓ | ✓ | ||

| 50×100×15, 22 | 5000 | ✓ | ✓ | ||

| 55×55×22 | 3025 | ✓ | |||

| 60×60×22 | 3600 | ✓ | ✓ | ||

| 75×75×22 | 5625 | ✓ | ✓ | ||

| 75×100×22 | 7500 | ✓ | |||

| 100×100×22 | 10000 | ✓ | ✓ | ||

| 100×150×22 | 15000 | ✓ | ✓ | ||

| 150×150×22 | 22500 | ✓ | |||

| Diameter×Thickness | Φ 40×15 | 1526 | ✓ | ||

| Φ 40×22 | 1526 | ✓ | |||

| Φ 50×13, 15 | 1923 | ✓ | |||

| Φ 50×22 | 1923 | ✓ | |||

| Φ 60×18 | 2826 | ✓ | |||

| Φ 60×22 | 2826 | ✓ | |||

| Φ 70×22 | 3847 | ✓ | |||

| Φ 1000 ×22 | 31400 | ✓ | |||

How to Choose the Right Size of the Silicon Carbide Foam Filter?

| Alloy / Process | Unit Surface Area Iron Quantity / R (kg/cm²) |

| Gray Iron, Copper-Aluminum Alloy | 3.2 ~ 4.2 |

| Spheroidal Graphite Iron | 1.6 ~ 2.1 |

| Chilled Cast Iron | 0.8 |

| In-Mold Pregnant | 0.8 |

- Calculate the required effective surface area of the filter (area through which molten metal flows) using the formula S=G/R, where G is the total molten metal to be filtered, and R is the filter’s filtration capacity per unit area.

- Verify the effective area against the flow restriction area of the pouring system. The recommended ratio is 1:3 for ductile iron, and 1:2 for gray iron and nodular cast iron.

- Add the support edge area (typically 5-15 mm) to determine the total filter area needed, then choose the filter size and quantity based on the total area and model specifications.

- Alternatively, filter size and quantity can be determined by considering the molten metal weight, the number of inner runners, the filtration capacity, and the filter specifications.

- Thicker filters offer better strength and efficiency, but at a higher cost. For optimal performance, recommended thicknesses are: 15-22 mm for 40-75 mm size, 22-25 mm for 75-120 mm size, 25-30 mm for 120-150 mm size, and 30-40 mm for sizes above 150 mm.

How to Choose a Suitable Pore Size of the Silicon Carbide Foam Filter?

The selection of the silicon carbide foam filter’s pore size mainly depends on the material of the molten metal, pouring temperature, casting size, and the purity of the molten metal. Since different molten metal materials have varying flow characteristics, the choice of pore size can differ significantly.

- Ductile iron castings typically use 10 PPI or 15 PPI products.

- Gray iron and cast copper generally use 15 PPI or 20 PPI products.

- Aluminum alloy castings commonly use 20 PPI or 30 PPI products.

- Nodular cast iron typically uses 30 PPI products.

Silicon Carbide Foam Filter Filtration Capacity

| Size (mm) | 10ppi | 20ppi | 30ppi | |||

| Filter Capacity (kg) | Flow Rate (Kg/s) | Filter Capacity (kg) | Flow Rate (kg/s) | Filter Capacity (kg) | Flow Rate (kg/s) | |

| Grey Iron | Grey Iron | Grey Iron | Grey Iron | Grey Iron | Grey Iron | |

| 40×40×15 | 64 | 4 | 50 | 3 | 42 | 2 |

| 40×40×22 | 64 | 4 | 50 | 3 | 42 | 2 |

| 50×30×22 | 60 | 4 | 47 | 3 | 40 | 2 |

| 50×50×15 | 100 | 6 | 78 | 3.5 | 66 | 3 |

| 50×50×22 | 100 | 6 | 78 | 3.5 | 66 | 3 |

| 60×60×15 | 144 | 9 | 112 | 6 | 95 | 5 |

| 75×50×22 | 150 | 9 | 116 | 6 | 99 | 5 |

| 75×75×22 | 220 | 14 | 175 | 10 | 149 | 8 |

| 100×50×22 | 200 | 12 | 155 | 9 | 133 | 7 |

| 100×75×22 | 300 | 18 | 232 | 13 | 199 | 11 |

| 100×100×22 | 400 | 24 | 310 | 18 | 265 | 15 |

| 150×150×22 | 900 | 54 | 698 | 40 | 596 | 33 |

| 200×200×30 | 1600 | 95 | 1240 | 58 | 1060 | 48 |

| Dia 40×22 | 40 | 3 | 39 | 2 | 33 | 2 |

| Dia 50×22 | 70 | 4.5 | 61 | 4 | 52 | 3 |

| Dia 60×22 | 100 | 6.5 | 88 | 5 | 75 | 4 |

| Dia 70×22 | 150 | 8.8 | 119 | 7 | 102 | 6 |

| Dia 75×22 | 170 | 10 | 137 | 8 | 117 | 6.5 |

| Dia 80×22 | 200 | 11 | 156 | 9 | 133 | 7 |

| Dia 90×22 | 240 | 14 | 197 | 11 | 169 | 9 |

| Dia 100×22 | 280 | 17 | 243 | 14 | 208 | 12 |

| Dia 125×22 | 400 | 24 | 380 | 22 | 325 | 18 |

| Dia 150×22 | 700 | 38 | 548 | 32 | 468 | 26 |

| Dia 200×30 | 1240 | 67 | 973 | 56 | 832 | 46 |

Silicon Carbide Foam Filter Features

- High Thermal Stability: Can withstand high temperatures (up to 1500℃), making them suitable for molten metal filtration.

- High Strength: Offers excellent mechanical strength, ensuring durability during metal pouring.

- Good Filtration Efficiency: Effectively filters out impurities, improving metal quality.

- Low Pressure Drop: Ensures smooth molten metal flow while minimizing pressure loss.

- Corrosion Resistance: Resistant to corrosion from molten metals, extending filter life.

- Lightweight and Easy Handling: Despite their strength, they are lightweight and easy to handle.

- Porosity Control: Can be manufactured with controlled porosity for specific filtration needs.

Silicon Carbide Foam Filter Applications

- Metallurgy: Used in foundries to filter molten metals like iron, steel, and non-ferrous alloys, improving metal purity and casting quality.

- Casting: Used to refine the quality of castings, reduce defects like porosity, and enhance surface finish.

- Steel Industry: Helps in manufacturing high-quality steel by filtering molten steel before casting.

- Aluminum Casting: Widely used in aluminum and its alloys to remove impurities and improve casting integrity.

- Automotive Industry: Used in producing components such as engine blocks and other vehicles’ cast parts

Silicon Carbide Material Properties

Silicon Carbide Material Grades

Reaction bonded silicon carbide (RBSiC) is made by mixing SiC, carbon, and binder, then infiltrating with silicon at high temperature. The vapor-phase method reduces free silicon to under 10%, improving performance. The result is a silicon-silicon carbide composite (SiSiC), not pure SiC.

SiC powder + C powder + binder mixed → forming → drying → protective atmosphere for degassing → high-temperature silicon infiltration → post-processing.

Reaction Bonded SiC Advantages:

- Low sintering temperature

- Low production cost

- High material densification

- Carbon and silicon carbide framework can be pre-machined into any shape

- Shrinkage during sintering is within 3%, aiding dimension control

- Significant reduction in the need for finishing, ideal for large, complex components

Reaction Bonded SiC Disadvantages:

- Residual free silicon in the sintered body after processing

- Reduced strength compared to products from other processes

- Decreased wear resistance

- Free silicon is not resistant to corrosion from alkaline substances and strong acids (e.g., hydrofluoric acid)

- Limited usage due to corrosion susceptibility

- High-temperature strength is impacted by free silicon

- Typical usage temperature is limited to below 1350-1400°C

Pressureless sintered silicon carbide refers to the densification sintering of samples with varying shapes and sizes at 2000–2150°C without applying external pressure and using an inert gas atmosphere, by incorporating suitable sintering additives. The sintering process can be categorized into solid-phase sintering (SSiC) and liquid-phase sintering (LSiC).

Solid-Phase Sintering SiC (SSiC) Properties:

- High Sintering Temperature: Requires a high sintering temperature (>2000°C).

- High Purity Requirement: The raw materials must be of high purity.

- Low Fracture Toughness: The sintered body has lower fracture toughness and tends to undergo transgranular fracture.

- Clean Grain Boundaries: There is essentially no liquid phase, and the grain boundaries are relatively “clean.”

- Stable High-Temperature Strength: High-temperature strength remains stable up to 1600°C without significant changes.

- Grain Growth: At high temperatures, grain growth is easy, leading to poor grain uniformity.

- High Crack Sensitivity: The material is highly sensitive to crack strength.

Liquid-Phase Sintering SiC (LSiC) Properties:

- Lower Sintering Temperature: Compared to solid-state sintering, the sintering temperature is lower.

- Smaller Grain Size: The grain size is smaller, with better uniformity of grains.

- Improved Fracture Toughness: Due to the introduction of a liquid phase at the grain boundaries, the fracture mode shifts to intergranular fracture, significantly improving fracture toughness.

- Additive Influence: Uses multi-component eutectic oxides (e.g., Y2O3-Al2O3) as sintering additives, promoting densification.

- Reduced Crack Sensitivity: Liquid-phase sintering reduces the material’s sensitivity to crack strength.

- Weakened Interface Bonding: The introduction of the liquid phase weakens the bonding strength at the grain boundaries.

Pressureless sintered boron carbide combines high purity and the excellent mechanical properties of boron carbide for use in both ballistic armor and semiconductor manufacturing.

Hot-Pressed SiC Advantages:

- Enables sintering at lower temperatures and shorter times, resulting in fine grains, high relative density, and good mechanical properties.

- The simultaneous heating and pressing facilitate particle contact diffusion and mass transfer.

- Suitable for producing silicon carbide ceramics with good mechanical performance.

Hot-Pressed SiC Disadvantages:

- The equipment and process are complex.

- High demands on mold material.

- Limited to producing simple-shaped parts.

- Low production efficiency.

- High production costs.

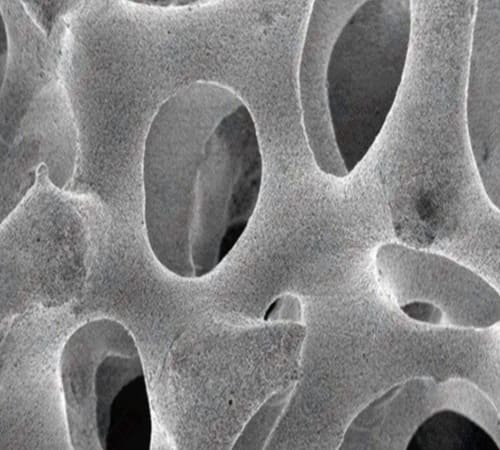

Recrystallized Silicon Carbide (RSiC) is a pure silicon carbide ceramic made via high-temperature evaporation-condensation, with a porous, high-strength structure, offering excellent heat, corrosion, and thermal shock resistance, used in kiln furniture, nozzles, and chemical components.

Recrystallized SiC Properties & Applications:

- The sintering process, based on evaporation-condensation, doesn’t cause shrinkage, preventing deformation or cracking.

- RSiC can be shaped through methods like casting, extrusion, and pressing, and its shrinkage-free firing allows for precise dimensions.

- After firing, recrystallized RSiC contains 10%-20% residual porosity, primarily influenced by the green body’s porosity, providing a foundation for porosity control.

- The sintering mechanism creates interconnected pores, making RSiC suitable for applications in exhaust and air filtration.

- RSiC has clean grain boundaries, free from glass and metal impurities, ensuring high purity and retaining SiC’s superior properties for demanding high-performance applications.

Hot Isostatic Pressed Silicon Carbide (HIPSiC) is a high-performance ceramic produced via hot isostatic pressing. Under high temperature (around 2000 ℃) and uniform high-pressure gas (typically argon), silicon carbide powder is densified into a nearly pore-free structure.

Hot Isostatic Pressed SiC Advantages:

- Uniform mictrostructure and fine grain size

- Low sintering temperature and time

- High density

- High purity and component control

Hot Isostatic Pressed SiC Disadvantages:

- Difficult packaging technology

- High initial investment and operational costs

- Limited for large or complex shapes

Spark Plasma Sintering Silicon Carbide is a high-performance ceramic produced using spark plasma sintering technology. This process employs pulsed current and pressure to rapidly density silicon carbide powder at relatively low temperatures (around 1800-2000 ℃) in a short time.

Spark Plasma Sintering SiC Properties:

- Faster heating rate

- Lower sintering temperature

- Shorter sintering time

- Fine and uniform grains

- High density

- Appliable for small and precision parts

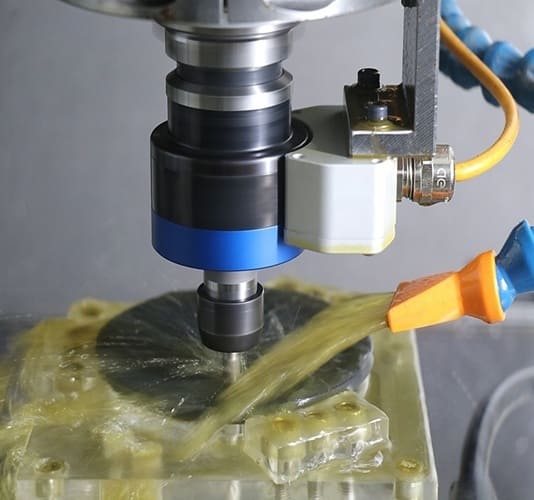

Silicon Carbide Ceramic Machining

Silicon Carbide (SiC) is a highly durable ceramic material with extreme hardness (9.5 Mohs), thermal stability (up to 1650 ℃), and resistance to wear, corrosion, and high temperatures. However, machining silicon carbide presents challenges due to its extreme hardness and brittleness. Specialized techniques and tools are required to achieve precise cuts and shapes. The common machining methods include:

- Diamond Grinding: Diamond tools are used to achieve smooth surfaces and precise shapes.

- Laser Cutting: Suitable for cutting thin SiC materials. Laser cutting offers high precision and minimal material waste.

- Ultrasonic Machining: This method uses high-frequency vibrations to cut and shape brittle materials like SiC without causing cracks.

- Electrical Discharge Machining (EDM): A non-traditional method that uses electrical sparks to remove material, effective for hard ceramics like SiC.

- Grinding With CBN Tools: Cubic boron nitride (CBN) tools can be used for grinding SiC, providing an alternative to diamond grinding for certain applications.

- Water Jet Cutting: Using a high-pressure jet of water, sometimes with abrasive particles, to cut through SiC. This method is useful for cutting complex shapes.

Silicon Carbide Ceramic Packaging

Silicon Carbide ceramic products are typically packaged in vacuum-sealed bags to prevent moisture or contamination and wrapped with foam to cushion vibrations and impacts during transport, ensuring the quality of products in their original condition.

Download

Get A Quote

We will check and get back to you in 24 hours.