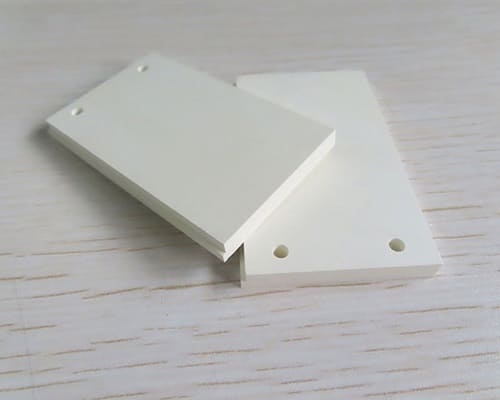

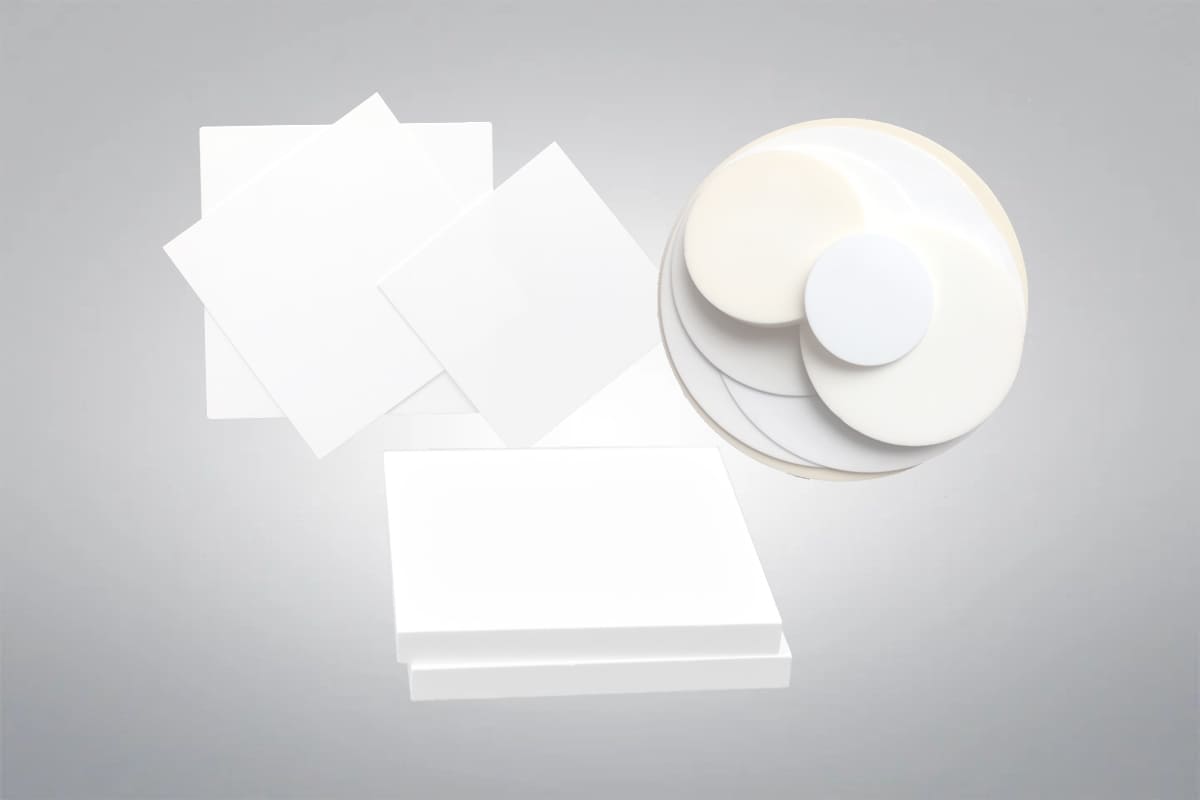

Boron Nitride Plate/Sheet/Disc

Boron Nitride Plate/Sheet/Disc

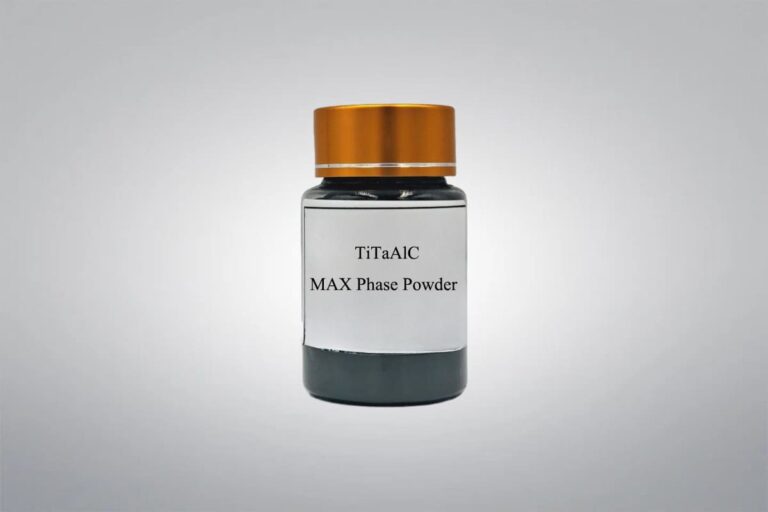

Material Grade: Grade A, Grade AX05, Grade HP, M/M26, ZSBN, HMBN1000, HMBN2000, HMBN3000, HMBN4000, HMBN5000, etc.

Boron Nitride Plate/Sheet/Disc is made of hot-pressed boron nitride ceramic with excellent electrical insulation, thermal stability, and chemical inertness. As a leading supplier and manufacturer of premium boron nitride products, we can supply high-quality boron nitride plates, sheets, and discs with various specifications and competitive prices, offering customized solutions to meet specific requirements.

Or email us at sales@heegermaterials.com.Boron Nitride Plate/Sheet/Disc Data Sheet

| Reference: | HM1307 |

| Material Grade: | Grade A, Grade AX05, Grade HP, M/M26, ZSBN, HMBN1000, HMBN2000, HMBN3000, HMBN4000, HMBN5000, etc. |

| Color: | White |

| Melting Point: | 2937 ℃ |

| Density: | 1.9-2.2 g/cm3 |

| Dielectric Constant: | 4.3 |

Boron Nitride Plate/Sheet/Disc

Boron Nitride plates, sheets, and discs are crafted from high-purity boron nitride powder using an advanced vacuum hot press sintering process. These materials offer excellent thermal and electrical insulation and high thermal conductivity. They can withstand rapid temperature changes without significant expansion or contraction. Low friction and high lubrication properties are ideal for applications requiring reduced friction and wear. Chemically inert, they resist reactions with most chemicals, acids, and bases, ensuring stability in corrosive environments. Available in customizable sizes, they are suitable for various research and industrial applications. Advanced Ceramics Hub can also supply boron nitride products with high-purity and different additives based on specific requirements.

Boron Nitride Plate Boron Nitride Sheet Boron Nitride Disc

Boron Nitride Plate/Sheet/Disc Advantages

- Low density

- High resistivity

- High breakdown voltage

- High thermal conductivity

- Low coefficient of thermal expansion

- Good thermal shock resistance

- High working temperature under vacuum and gas protection

- Good corrosion resistance

- No wetting with metals (no oxidation)

- Good machinability

Boron Nitride Plate/Sheet/Disc Applications

- Electronics Industry: Used as heat sinks, insulating substrates, carrier plates, trays, and heater components in semiconductor processing.

- High-Temperature Industries: Used as furnace linings and hot-press molds for high-temperature applications.

- Aerospace: Used as radar windows, antenna covers, and thermal protection components in high-temperature environments.

- Chemical Industry: Used as corrosion-resistant liners, sealing gaskets, and other components.

- Research and Development: Used as carrier plates for high-temperature experiments, crucible gaskets, and insulation/support components in high-vacuum environments.

Boron Nitride Material Properties

Boron Nitride Material Grades

Boron Nitride, with a glassy B2O3 binder, is highly machinable and suitable for most refractory applications. Grade A, used for over 50 years in legacy semiconductor and defense equipment, can produce components up to 410mm x 495mm x 245mm, but its hygroscopic binder needs moisture protection.

Grade A Composition:

- hBN>99.8%

Grade A Applications:

- High-temperature electrical insulators and vacuum furnace supports with electrical resistivity, strength, and thermal shock resistance.

- Crucibles and containers for high-purity molten metals.

- Insulators and fixtures for ion implantation systems requiring high temperature purity and electrical insulation.

- Radar components and antenna windows needing precise electrical and thermal properties.

- Setter plates for processing advanced materials requiring stable, inert surfaces.

- Nozzles for powdered metal spraying.

Boron Nitride Grade AX05 is a high-purity hexagonal boron nitride (hBN) solid, ideal for applications where corrosion resistance is more critical than wear resistance. As a diffusion-bonded ceramic without B2O3 binders, it is non-wet by most molten metals. Its ultra-purity makes it suitable for high-purity molten metal crucibles and applications requiring high thermal conductivity, such as nozzles with small orifices.

Grade AX05 Composition:

- hBN>99.5%

Grade AX05 Key Properties:

- Chemical: Inert, non-wet by molten metals, glasses, and salts; stable for nozzles, crucibles, and supports.

- Thermal: Low expansion, high conductivity, over 2000°C in inert atmospheres, excellent thermal shock stability.

- Mechanical: Higher strength at elevated temperatures, outperforming other boron nitrides.

- Electrical: Microwave transparent, high resistivity, low loss; ideal for high-power insulators.

- Machinability: Machinable to tight tolerances with high-speed tools, threads can be machined (avoid cutting oils).

Grade HP is a versatile Boron Nitride grade known for low thermal expansion, high thermal shock resistance, and strong electrical properties. Developed with a calcium borate glass binder, it offers better moisture resistance than Grade A, making it suitable for applications in inert or vacuum atmospheres up to 1000°C. It is highly machinable and widely used in light metal applications like Al, Ti, Mg, and Zn, with sizes up to 410mm x 495mm x 245mm.

Grade HP Composition:

- hBN>90%

- Calcium Borate

Grade HP Key Properties:

- Chemical: High corrosion resistance; ten times the moisture resistance of other boron nitrides due to the addition of calcium, forming calcium borate with boric oxide.

- Thermal: Excellent thermal shock resistance and conductivity; commonly used in light metal applications like Al, Ti, Mg, and Zn.

- Electrical: Low dielectric constant; ideal for high-temperature insulators.

- Machinability: Can be machined using standard high-speed tool steel equipment; grinding for stringent tolerances.

Grade M/M26 is a hydrophobic advanced ceramic made of boron nitride and silica, offering complete moisture resistance. It meets the MIL-I-10A L542 test, demonstrating reliability in severe electrical applications. With excellent refractory properties up to 1400°C, it excels in thermal shock resistance.

Grade M/M26 Composition:

- M: hBN 40%+SiO2 60%

- M26: hBN 60%+SiO2 40%

Grade M/M26 Applications:

- High-temperature electrical insulators and vacuum furnace supports with electrical resistivity, strength, and thermal shock resistance.

- Crucibles and containers for high-purity molten metals.

- Radar components and antenna windows needing precise electrical and thermal properties.

- Tools and refractories for glass forming that offer non-wetting properties and do not contain B2O3 in their contacts.

Grade ZSBN is a composite material that combines the thermal performance and machinability of hot-pressed boron nitride with the strength, wear resistance, and non-reactivity of silicon carbide and zirconia. Developed for demanding molten metal applications, it excels in thermal conductivity, wear resistance, and corrosion resistance. With zirconia particles dispersed within boron nitride platelets, ZSBN offers superior wear resistance while maintaining the non-wetting properties of hexagonal Boron Nitride. It is ideal for continuous casting break rings, molten metal atomizing nozzles, glass contact components, and various guides and rollers in light metal baths like Zn, Mg, Al, and Li.

Grade ZSBN Composition:

- hBN>45%

- ZrO2<45%

- Borosilicate <10%

Grade ZSBN Key Properties:

- Chemically: Unparalleled resistance to molten metal wetting due to boron nitride content.

- Thermally: Excellent high-temperature operation and thermal shock resistance.

- Mechanically: Excellent wear-resistance, increased strength from zirconia and silicon carbide, and remarkable corrosion-resistance over a wide range of temperatures.

- Machinability: Easily machinable to complex shapes with tolerances of 0.002” or better, quickly and inexpensively.

Grade ZSBN Applications:

- Break rings for continuous casting of metals

- Components

- Crucibles

- Deck plates

- Heat treatment fixtures

- High temperature bearings

- High temperature mechanical components

- High temperature valves

- Jigs

- Molds

- Molten metal and glass castings

- Muffles

- Nozzles for transfer or atomization

- Side dams

- Spacers

HMBN1000 is a high-purity, hot-pressed boron nitride designed for demanding high-temperature applications. It offers low thermal expansion, excellent thermal shock resistance, and superb thermal conductivity. With good chemical resistance to molten metal and glass, it also provides low friction and electrical insulation with high dielectric strength. Easily machinable, HMBN1000 is ideal for applications requiring minimal binder, and can be produced up to 300mm in diameter and length.

HMBN1000 Applications:

- Electric propulsion discharge channels for Hall Effect Thrusters

- Setter plates for high temperature furnaces

- Crucibles for molten glass and metals

- Electrical insulators for high temperatures and high voltages

- Vacuum feedthroughs

- Plasma chamber lining and fittings

- Nozzles for non-ferrous metals and alloys

- Thermocouple protection tubes and sheaths

- Laser supports

HMBN2000 is a hot-pressed boron nitride/silica composite known for its excellent dielectric performance, insulation, and thermal shock resistance. It offers low thermal expansion and good flexural strength, while being easily machinable.

HMBN2000 Applications:

- Electric propulsion discharge channels for Hall Effect Thrusters

- Plasma/corona insulators

- Plasma constraints in PVD systems

- Wear and corrosion resistance

- Ultra high vacuum insulators

HMBN3000 is a high-purity, binder-free hot-pressed boron nitride designed for demanding high-temperature applications. It features very low thermal expansion, superb thermal shock resistance, excellent thermal conductivity, and minimal thermal cycling. Easily machinable to tight tolerances, it offers good chemical resistance to molten metals and low friction. Non-reactive with graphite and refractory metals up to 2000°C, it also provides high dielectric strength and electrical resistivity. Ideal for high-temperature applications, HMBN3000 can be machined from large billets up to 490mm x 490mm x 400mm.

HMBN3000 Applications:

- Setter plates for high temperature furnaces

- Crucibles for non-oxide ceramics, phosphors, and metals

- Electrical insulation for extremely high temperatures and high voltages

- Components exposed to molten salts

- Hall Effect Thruster insulators

- Nozzles for non-ferrous metals and alloys

- Thermocouple protection tubes and sheaths

- Laser supports

HMBN4000 is a strong, hard, hot-pressed boron nitride designed for demanding applications. It offers low thermal expansion, excellent thermal shock resistance, and good thermal conductivity. This economical hexagonal Boron Nitride grade is easily machinable to tight tolerances, with low thermal cycling and chemical resistance to molten metals up to 1000°C. Its lubricity provides low friction, and it retains high dielectric strength and electrical resistivity up to 1000°C. HMBN4000 is ideal for applications requiring strength, and can be machined from large billets up to 490mm x 490mm x 400mm.

HMBN4000 Applications:

- Setter plates for furnaces

- Crucibles for non-oxide ceramics, phosphors, and metals

- Electrical insulation for high temperatures and high voltages

- Components exposed to molten salts

- Nozzles for non-ferrous metals and alloys

- Thermocouple protection tubes and sheaths

HMBN5000 is a high-purity, hot-pressed boron nitride with a silica matrix, offering excellent machinability, moisture resistance, and high fracture toughness. This versatile grade features low thermal shock, with the ability to exceed temperature limits for short periods without damage. It maintains its shape and properties after cooling and can be machined from large billets up to 490mm x 490mm x 400mm. HMBN5000 also provides outstanding electrical insulation, with high dielectric strength and resistivity up to 1000°C, making it ideal for demanding applications.

HMBN5000 Applications:

- Microwave components

- Electrical insulation for high temperatures and high voltages

- Hall Effect Thruster insulators

Boron Nitride Machining

The Advanced Ceramic Hub machining center is equipped with multiple CNC lathes and CNC milling machines, backed by extensive machining experience. We offer customized boron nitride ceramic products and profiles with extremely tight tolerances, tailored to customer requirements. During the machining process, the following precautions should be observed:

- Boron nitride ceramic materials can be machined using standard high-speed steel cutting tools. For harder and composite materials, carbide or diamond tools are recommended.

- Grinding operations can be performed as needed, and standard taps and dies can be used to machine threads.

- The machining process should always be kept dry, with no need for cutting oils or coolants.

- Cutting tools should be sharp and clean, and tools with negative rake angles should not be used.

- Care should be taken when clamping and securing materials to avoid applying excessive pressure. Climb milling techniques should be used to prevent edge and corner chipping.

Boron Nitride Packaging

Boron Nitride Ceramic products are typically packaged in vacuum-sealed bags to prevent moisture or contamination, wrapped with foam to cushion vibrations and impacts during transport, ensuring the quality of products in their original condition.

Download

Get A Quote

We will check and get back to you in 24 hours.