Powering Innovation With Precision Ceramics

Advanced Ceramics Hub is a leading supplier of high-performance ceramic materials, offering a wide range of advanced ceramics, including Boron Nitride (BN), Alumina (Al2O3), Aluminm Nitride (AlN), Silicon Carbide (SiC), Zirconia (ZrO2), etc. With advanced manufacturing technology and stringent quality control, we are committed to delivering high-reliability, high-quality ceramic solutions to drive technology innovation and industrial advancement.

Cutting-Edge Popular Materials

Empowering the Future of Technology

Advanced technical ceramics have become core materials for many high-tech products, because of their excellent properties such as high-temperature resistance, corrosion resistance, strong insulation, and mechanical strength. They are widely applied in the following fields:

Semiconductor

Ceramic Electrostatic Chucks, PBN Crucibles, etc.

New Energy

Solid-state Batteries, Hydrogen Fuel Cells, etc.

Medical

ZrO2 Dental Implants, Surgical Tools, etc.

Aerospace

SiC Turbine Blades, Thermal Protection Coatings, etc.

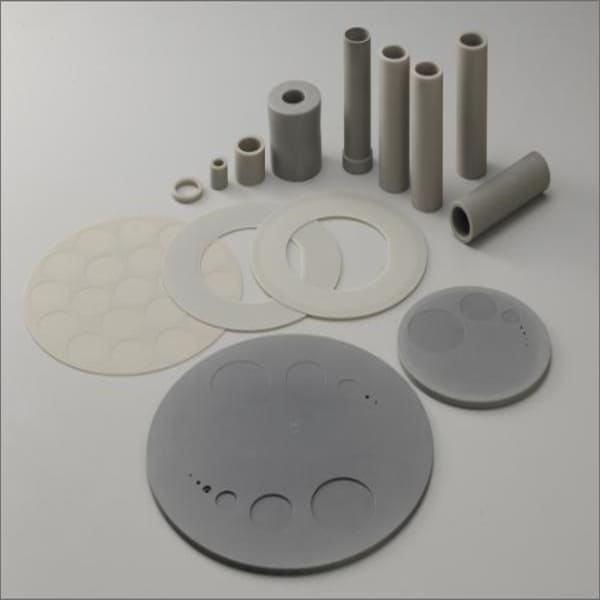

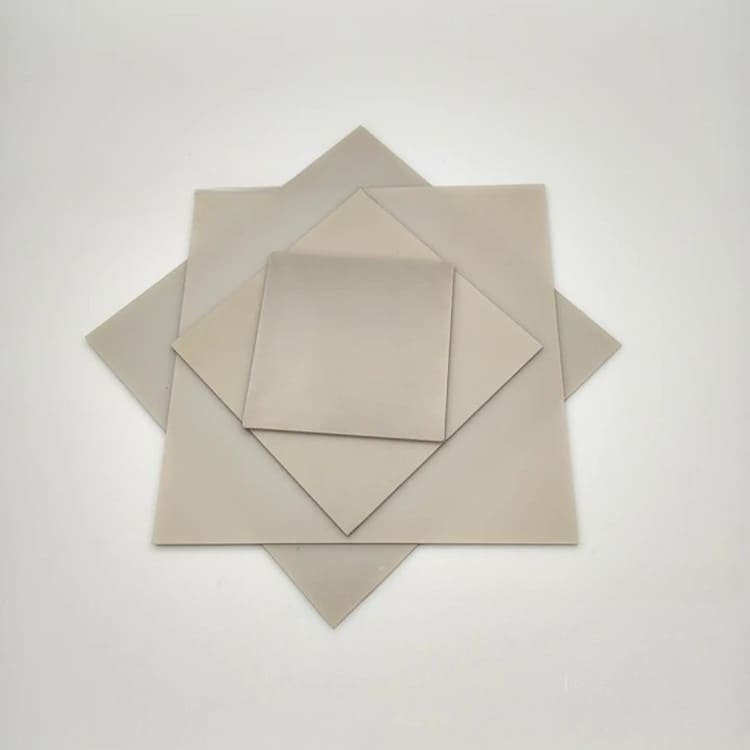

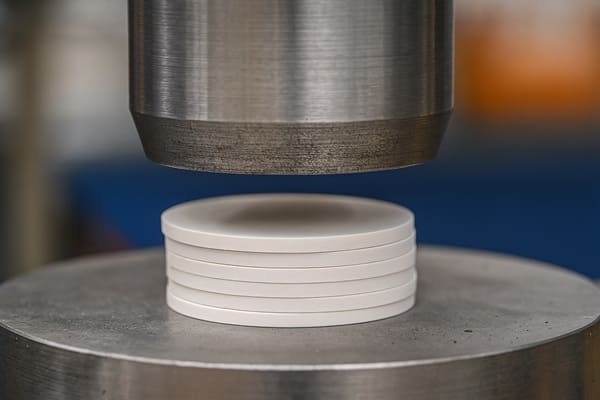

Most Popular Product Forms

At Advanced Ceramics Hub, we offer the most sought-after technical ceramic solutions in rods, discs, tubes, and custom shapes. Our ceramics deliver superior performance, tight tolerances, and reliability in challenging environments.

Advanced Manufacturing & Processing Capabilities

10+

Years of experience

At Advanced Ceramic Hub, we master the entire process chain from raw material synthesis to precision manufacturing. Our state-of-the-art manufacturing and processing capabilities ensure precision and reliability in every product.

We offer customized, one-stop semiconductors, aerospace, and healthcare solutions from material selection to mass production.

We engineer ceramics with exceptional thermal conductivity, mechanical strength, and extreme-environment stability through high-purity powder processing and advanced sintering technologies. Our precision machining center delivers components with tight tolerance via laser cutting and grinding, meeting stringent demands in semiconductors and aerospace. Rigorous X-ray inspection and thermal shock testing ensure product reliability.

What our Clients say

At Advanced Ceramics Hub, our clients include leading research institutions, universities, and R&D departments of leading enterprises. We take pride in the trust and satisfaction of our clients. Their feedback reflects the quality and reliability we consistently deliver.

Jhon D.

Los Angeles, CA

“Advanced Ceramic Hub’s AlN substrate improved our power module thermal efficiency by 35%, extending device lifespan over 2X.”

Sarah Davis

Brooklyn, NY

“We’ve been using their ceramics for our high-performance components, and the results have been excellent.”

Michael Johnson

Houston, TX

“The products are strong, precise, and durable, improving component reliability with exceptional customer service.”

LATEST ARTICLES & BLOGS

Analysis of Sintering Brittleness in Dry-Pressed Ceramics: A Multidimensional Perspective from Raw Materials to Manufacturing Processes

Unveiling the Phenomenon of “Inverse Densification” in Materials Sintering: Why Sometimes Does the Green Body Expand?

Doping Modification of Ceramic Materials: Key Technologies for Performance Enhancement

contact us

Your Advanced Ceramic Partner

From material selection to custom technical support, the Advanced Ceramics Hub’s professional team ensures you get the best solutions. Looking forward to hearing from you! We will get back in 24 hours.

Call now

1-925-385-8104

Email now

sales@heegermaterials.com