Zirconia Toughened Alumina Substrate

Zirconia Toughened Alumina Substrate

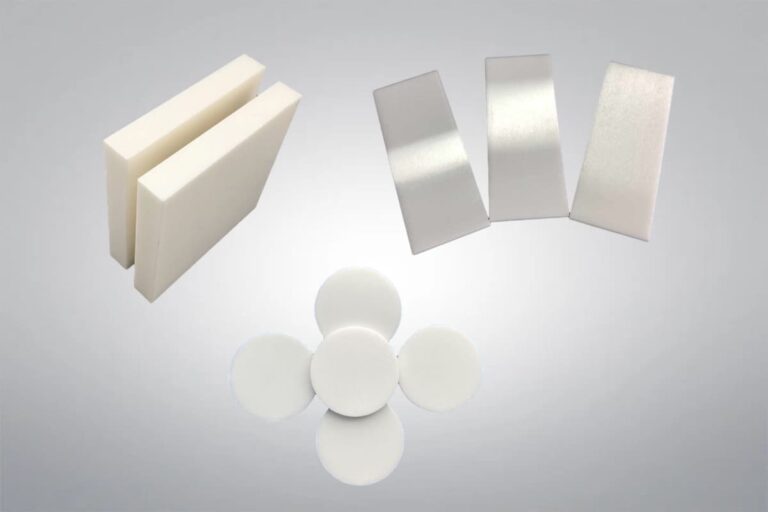

Zirconia Toughened Alumina Substrate is a high-performance ceramic material primarily composed of high-purity aluminum oxide (Al2O3) and zirconia (ZrO2), offering superior bending strength compared to standard alumina substrates. As a leading supplier and manufacturer of premium alumina products, we can supply high-quality ZTA substrates with various specifications and competitive prices, offering customized solutions to meet specific requirements.

Or email us at sales@heegermaterials.com.Zirconia Toughened Alumina Substrate Data Sheet

| Reference Code: | HM2610 |

| Thickness: | Cast Substrate: 0.25-1.00 mm Dey-pressed Substrate: Customized |

| Size: | Length: ≤200 mm Width: ≤200 mm |

| Shape: | The standard rectangular shape or customized |

Zirconia Toughened Alumina Substrate

Zirconia Toughened Alumina (ZTA) Substrate is mainly made from high-purity aluminum oxide (Al2O3) and zirconia (ZrO2) and is widely applied in high-power electric vehicles, aerospace, and defense. It possesses superior bending strength compared to standard alumina substrates and has excellent current carrying and heat dissipation capabilities, commonly used for IGBT modules and LED packaging. Zirconia Toughened Alumina (ZTA) substrates are ideal materials for high-performance circuit carriers in DBC ceramic-metal composite substrates and LED circuit boards. Advanced Ceramics Hub can supply customized solutions in terms of size, shape, and surface treatment to meet diverse industrial and research requirements.

Zirconia Toughened Alumina Substrate Specifications

| Item | Unit | ZTA |

| Dimensions | Inch (max) | 5.5”×7.5”, or customized |

| Tolerance | ±1% | |

| Thickness | mm | 0.25-1.0 |

| 5.5”×7.5” or customized | ±10% | |

| Hole | mm | Φ0.2 or customized |

| Tolerance | ±0.6% | |

| Warpage | mm | 0.005/mm |

Zirconia Toughened Alumina Substrate Features

- Achieving excellent surface roughness with a homogeneous fine microstructure.

- It has more than 1.5 times the bending strength compared to alumina substrates and aluminum nitride substrates.

- It has 1.2 times the thermal conductivity compared to alumina substrates.

- Higher reflectivity than alumina substrates, with an enhanced version of high-reflectivity zirconia substrates, is also available.

- It possesses high electrical insulation properties with a low dielectric constant.

Zirconia Toughened Alumina Substrate Available Machining Processes

- Glaze Processing

- Laser Processing

- Multilayer

- Metallization

- Stamping Processing

- Surface Grinding

- Machining

Zirconia Toughened Alumina Substrate Applications

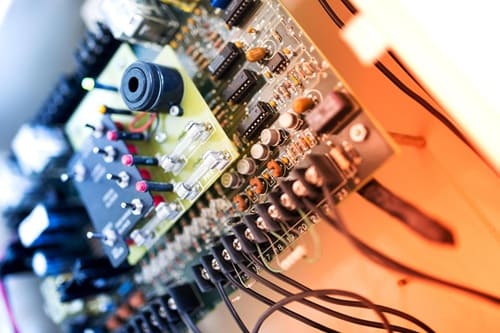

- Electronic Packaging Materials: ZTA ceramic substrates are widely used in electronic packaging materials for components such as power devices and integrated circuits (ICs) due to their excellent thermal conductivity, insulation, and mechanical strength.

- High-Power Electronic Devices: In high-power electronics, ZTA ceramic substrates are used to create efficient heat dissipation solutions, providing good thermal management and stable performance.

- LED Substrates: Due to their high thermal conductivity and excellent heat resistance, ZTA ceramics are used as substrates for LED lighting devices, helping to improve the stability and lifespan of the light sources.

- Microwave and RF Devices: ZTA ceramic substrates are used in microwave and RF applications for circuit boards. They offer low loss and good thermal stability and are ideal for communication and radar equipment.

- Laser and Optical Components: ZTA ceramic substrates are employed in the manufacturing of lasers and optical devices, providing stable optical performance for high-precision applications.

- Automotive Electronics: With the development of automotive electronics, ZTA ceramic substrates are used in certain automotive electronic control systems due to their resistance to high temperatures and vibrations.

Zirconia Toughened Alumina Material Properties

Zirconia Toughened Alumina Material Grades

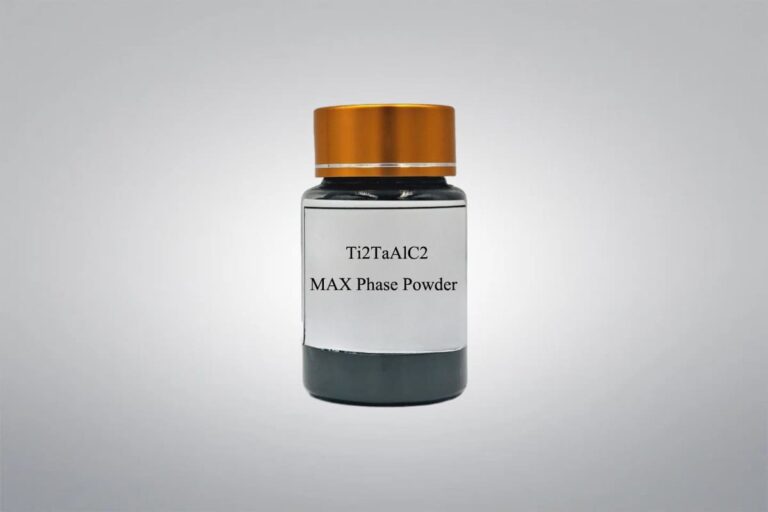

CeramAlloy ZTA is a high performance ceramic composite and a unique ceramic material by way of exhibiting a combination of high hardness, strength, wear and corrosion resistance resulting from its Alumina content, while still maintaining reasonably high fracture toughness resulting from its Zirconia content.

Applications:

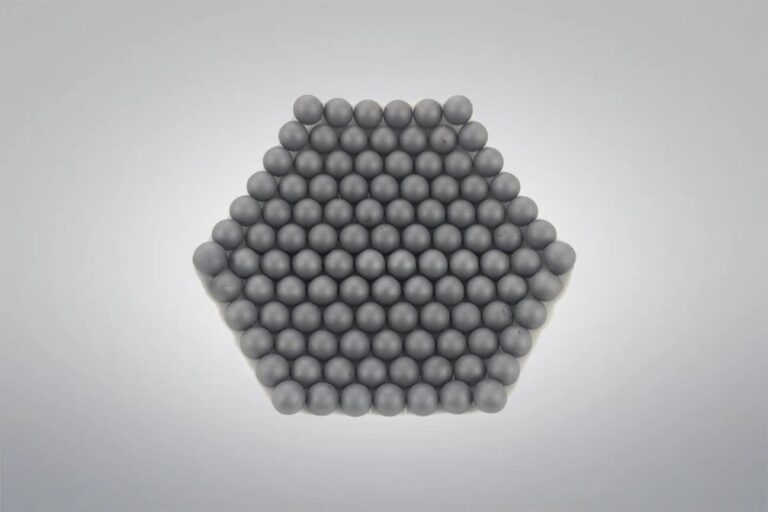

- High pressure equipment – ball valve balls and seats

- Rollers and guides for metal forming

- Thread and wire guides

- Deep well down-hole valves and seats

- Shaft bearings/bushings

Ultra Hard is a high performance ceramic composite and a unique ceramic material by way of exhibiting a combination of high hardness, strength, wear and corrosion resistance resulting from its Alumina content, while still maintaining reasonably high fracture toughness resulting from its Zirconia content.

Applications:

- High pressure equipment – ball valve balls and seats – particularly suitable for high flow/abrasive fluids

- Focusing nozzles for abrasive media

- Ultra high pressure pumping elements

- Deep well down-hole valves and seats

- Rollers and guides for metal forming

- Thread and wire guides

- Metal extrusion dies

Zirconia Toughened Alumina Ceramic Machining

Zirconia Toughened Alumina (ZTA) is a high-performance composite material that enhances toughness and strength by incorporating zirconia (ZrO₂) into alumina (Al₂O₃). Machining this material requires addressing its high hardness and brittleness. Key machining aspects include:

- Cutting: Utilizes diamond tools or laser cutting for precision and edge integrity.

- Grinding: Employs precision grinding to control surface roughness and dimensional tolerances.

- Drilling: Uses ultrasonic or diamond drills for micro-holes, ideal for electronic applications.

- Surface Finishing: Polishing or coating improves wear resistance and aesthetics.

ZTA machining is widely applied in precision component manufacturing, such as electronic substrates and medical implants.

Zirconia Toughened Alumina Ceramic Packaging

Zirconia Toughened Alumina Ceramic products are typically packaged in vacuum-sealed bags to prevent moisture or contamination and wrapped with foam to cushion vibrations and impacts during transport, ensuring the quality of products in their original condition.

Download

Get A Quote

We will check and get back to you in 24 hours.