Technical Ceramics for Aerospace: Top 5 High-Performance Materials & Their Critical Applications

Technical ceramics, also known as advanced or engineering ceramics, have revolutionized the aerospace industry by offering unparalleled performance in extreme environments. These materials are prized for their ability to withstand high temperatures, resist corrosion, and maintain structural integrity under intense mechanical and thermal stresses. As aerospace technologies push the boundaries of speed, altitude, and efficiency—think hypersonic jets and reusable spacecraft—technical ceramics have become indispensable. Their adoption is growing rapidly, driven by the need for lightweight, durable, and high-performance components that traditional materials like metals often cannot provide.

The significance of technical ceramics lies in their unique combination of properties: they are lighter than metals, yet stronger than many alloys at high temperatures, and they resist wear and chemical degradation. This makes them ideal for applications ranging from jet engine components to thermal protection systems on spacecraft. The objective of this article is to delve into the top five high-performance ceramic materials used in aerospace, exploring their properties, applications, and transformative impact. By understanding these materials, we can appreciate their role in shaping the future of aviation and space exploration.

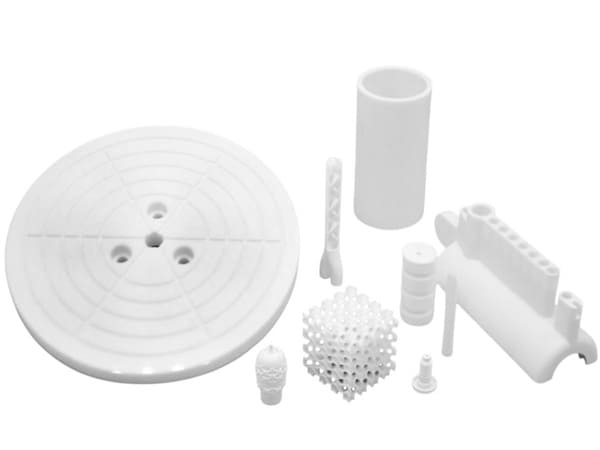

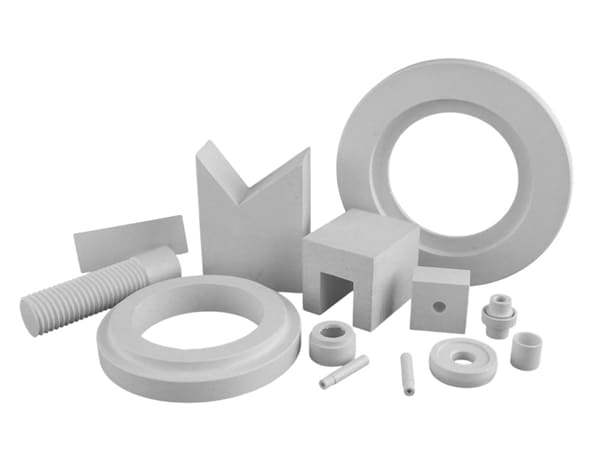

At Advanced Ceramics Hub, we specialize in high-quality technical ceramic products with a variety of materials and specifications, ensuring optimal performance for industrial and scientific applications.

What Are Technical Ceramics?

Key Characteristics of Technical Ceramics:

- High Hardness & Wear Resistance – Resistant to abrasion and ideal for cutting tools, bearings, and wear parts.

- Extreme Temperature Stability – Can withstand very high (up to 2000°C+) or cryogenic temperatures without degrading.

- Chemical Inertness – Resistant to corrosion, acids, alkalis, and harsh environments.

- Electrical Insulation or Conductivity – Some are excellent insulators (e.g., alumina), while others are conductive (e.g., silicon carbide for heating elements).

- Biocompatibility – Used in medical implants (e.g., zirconia for dental crowns).

- Low Thermal Expansion – Maintain dimensional stability under temperature fluctuations.

Common Types of Technical Ceramics:

| Category | Material | Key Properties | Common Applications |

| Oxide Ceramics | Alumina (Al₂O₃) | High hardness, electrical insulation, chemical resistance | Spark plugs, medical implants, electronic substrates, cutting tools |

| Zirconia (ZrO₂) | High strength, thermal shock resistance, and creep resistance | Dental crowns, hip implants, precision knives, fuel cell membranes | |

| Non-Oxide Ceramics | Silicon Carbide (SiC) | Extreme hardness, high thermal conductivity, oxidation resistance | Armor plates, semiconductor equipment, heating elements, abrasive nozzles |

| Boron Carbide (B₄C) | Ultra-hard, lightweight (3rd hardest material after diamond/cubic BN) | Body armor, sandblasting nozzles, neutron absorbers (nuclear reactors) | |

| Silicon Nitride (Si₃N₄) | High strength, thermal shock resistance, creep resistance | Bearings, turbine blades, engine components, cutting tools | |

| Composite Ceramics | Alumina-Titanium Carbide (AlTiC) | Enhanced wear resistance, toughness | Cutting inserts, precision machining tools |

| Zirconia-Toughened Alumina (ZTA) | Improved fracture toughness over pure alumina | Biomedical implants, industrial wear parts |

Notes:

- Oxide ceramics are typically more chemically stable but may have lower toughness.

- Non-oxide ceramics (SiC, Si₃N₄, B₄C) excel in extreme environments but are harder to sinter.

- Composites combine the strengths of multiple materials (e.g., AlTiC for wear-resistant tools).

Applications of Technical Ceramics:

- Electronics: Insulators, substrates, semiconductors.

- Automotive/Aerospace: Engine components, sensors, brake discs.

- Medical: Hip/knee implants, dental prosthetics.

- Industrial: Cutting tools, seals, pump components.

- Energy: Fuel cells, heat exchangers, nuclear reactor parts.

- Defense: Ballistic armor, missile nose cones.

Advantages Over Metals & Polymers:

| Property | Technical Ceramics | Metals | Polymers |

| Hardness | Extremely high (e.g., SiC, B₄C) | Moderate to high (e.g., steel) | Low (soft, prone to scratching) |

| Wear Resistance | Excellent (low friction, abrasion-resistant) | Good (but can wear over time) | Poor (soft, degrades with friction) |

| Temperature Stability | Withstands 1000°C+ (some up to 2000°C) | Loses strength at high temps (e.g., aluminum melts at ~660°C) | Degrades above 200–300°C (thermoplastics soften) |

| Corrosion Resistance | Chemically inert (resists acids, alkalis) | Prone to oxidation/rust (except stainless steel) | Vulnerable to solvents/UV degradation |

| Weight | Lightweight (lower density than metals) | Heavy (e.g., steel, titanium) | Very light (but weak structurally) |

| Electrical Properties | Insulators (Al₂O₃) or conductors (SiC) | Conductive (can short circuits) | Insulators (but static-prone) |

| Biocompatibility | Excellent (e.g., ZrO₂ for implants) | May corrode/release ions (e.g., Co-Cr alloys) | Can degrade or cause inflammation |

| Dimensional Stability | Low thermal expansion (stable under heat) | Expands significantly with heat | High thermal expansion (warps easily) |

Note:

- Ceramics outperform metals in high-temperature, corrosive, or wear-intensive environments.

- Ceramics surpass polymers in strength, thermal stability, and durability.

- Limitations of ceramics: Brittleness (low fracture toughness) and complex/expensive manufacturing.

Looking for top-quality technical ceramic products? Explore the Advanced Ceramics Hub’s selection.

Top 5 High-Performance Technical Ceramics

Technical ceramics are engineered materials designed for extreme conditions, offering superior hardness, thermal stability, and chemical resistance compared to metals and polymers. Below are the top 5 high-performance technical ceramics, each excelling in critical industrial, medical, and technological applications.

1. Silicon Carbide (SiC) – The Ultimate High-Temperature Ceramic

Silicon carbide is a standout material in aerospace due to its extreme hardness, high thermal conductivity, and oxidation resistance. With a Mohs hardness of 9, SiC is nearly as hard as diamond, making it ideal for components subject to abrasive wear. Its ability to conduct heat efficiently while maintaining structural integrity at temperatures up to 1,600°C is critical for high-performance applications.

Key Properties

✅ Extreme Hardness (9.5 Mohs, approaching diamond)

✅ Ultra-High Thermal Conductivity (120-270 W/mK)

✅ Superior Thermal Shock Resistance (withstands rapid temperature changes)

✅ Excellent Chemical Inertness (resists acids, alkalis, and oxidation)

✅ Semiconductor Capability (wide bandgap for high-power electronics)

In aerospace, SiC is used in:

- Turbine Blades: Enhance efficiency by withstanding the high temperatures and oxidative conditions in jet engines.

- Thermal Protection Systems: Protects spacecraft during atmospheric re-entry, where temperatures can exceed 2,000°C.

- High-Temperature Components: Used in exhaust systems and combustion chambers for their durability.

SiC’s lightweight nature (density ~3.2 g/cm³) reduces fuel consumption, a critical factor in aerospace design. However, its brittleness requires advanced manufacturing techniques, such as chemical vapor deposition, to ensure reliability.

2. Alumina (Al₂O₃) – The Most Versatile Industrial Ceramic

Alumina, or aluminum oxide, is valued for its excellent electrical insulation, wear resistance, and high compressive strength. With a melting point of 2,072°C and exceptional hardness, alumina is a versatile ceramic used in both structural and functional aerospace components. Its chemical stability ensures it resists corrosion even in aggressive environments.

Key Characteristics:

✔ Hardness: 9 Mohs (scratch-resistant)

✔ Max Service Temp: 1,750°C (3,182°F)

✔ Dielectric Strength: 15-20 kV/mm

✔ Density: 3.8-3.9 g/cm³

✔ Flexural Strength: 300-400 MPa (high-purity grades)

Performance Advantages:

- Best cost-to-performance ratio among ceramics

- Superior electrical insulation even at high temperatures

- Excellent biocompatibility (ISO 6474 compliant)

- Good chemical resistance to most acids and alkalis

- Multiple purity grades (96%-99.9%) for tailored applications

Key applications include:

- Insulators: Used in electrical systems to prevent unwanted current flow in high-temperature environments.

- Structural Components: Provides strength in lightweight frameworks for satellites and aircraft.

- Wear-Resistant Coatings: Applied to surfaces exposed to friction, extending component lifespan.

Alumina’s affordability compared to other technical ceramics makes it a popular choice, though its lower thermal shock resistance limits its use in rapid temperature change scenarios.

3. Zirconia (ZrO₂) – The Toughest Structural Ceramic

Zirconia, or zirconium dioxide, is renowned for its high fracture toughness, thermal stability, and low thermal conductivity. These properties make it an excellent choice for thermal barrier coatings, which protect engine components from extreme heat. Zirconia’s ability to withstand thermal cycling—repeated heating and cooling—ensures long-term reliability.

Exceptional Material Properties:

⚡ Fracture Toughness: 5-10 MPa·m½ (3× tougher than alumina)

⚡ Flexural Strength: 900-1,400 MPa (highest among oxides)

⚡ Biocompatibility: ISO 13356 certified for medical use

⚡ Wear Resistance: Extremely low coefficient of friction

⚡ Thermal Expansion: Close to steel (enables metal-ceramic joints)

Advanced Variants:

• Y-TZP (Yttria-Stabilized): 3mol% Y₂O₃ for optimal strength

• Mg-PSZ (Magnesia-Partially Stabilized): Superior thermal shock resistance

• Ce-TZP (Ceria-Stabilized): Highest toughness (up to 15 MPa·m½)

Applications in aerospace include:

- Thermal Barrier Coatings: Applied to turbine blades and combustors to reduce heat transfer, improving engine efficiency.

- Engine Components: Used in parts exposed to high thermal and mechanical stresses.

- Fuel Cell Systems: Supports power generation in spacecraft due to its ionic conductivity at high temperatures.

Zirconia’s phase transformation toughening mechanism enhances its durability, but its high density (5.68 g/cm³) can be a drawback in weight-sensitive applications.

4. Silicon Nitride (Si₃N₄) – The High-Strength Engineering Ceramic

Silicon nitride is prized for its high strength-to-weight ratio, thermal shock resistance, and low density (3.2 g/cm³). These properties make it ideal for lightweight, high-performance components in aerospace. Its ability to resist sudden temperature changes without cracking is particularly valuable in dynamic environments.

Key Properties:

✔ High Strength-to-Weight Ratio – Comparable to steel but 40% lighter

✔ Thermal Shock Resistance – Withstands rapid temperature changes up to 1,400°C (2,552°F)

✔ Low Thermal Expansion – Maintains dimensional stability under heat

✔ Wear & Corrosion Resistance – Outperforms metals in harsh environments

✔ Self-Lubricating – Low friction coefficient (excellent for bearings)

Grades & Compositions:

• Reaction-Bonded Si₃N₄ (RBSN) – Porous, lower cost

• Hot-Pressed Si₃N₄ (HPSN) – High density, superior strength

• Sintered Si₃N₄ (SSN) – Complex shapes, balanced properties

Applications include:

- Bearings: Reduce friction and wear in high-speed rotating systems, such as those in jet engines.

- Engine Parts: Used in valves and rotors for their durability and lightweight properties.

- Lightweight Structural Components: Supports airframes and spacecraft structures, reducing overall weight.

Silicon nitride’s excellent fatigue resistance ensures long service life, though its complex manufacturing process increases costs.

5. Boron Nitride (BN)

Boron nitride is unique for its excellent thermal conductivity, lubricity, and chemical inertness. Often compared to graphite for its slippery texture, BN excels in applications requiring heat dissipation or low friction. Its ability to remain stable at temperatures up to 2,000°C in inert atmospheres makes it valuable in aerospace.

Key Polymorphs & Properties

✔Hexagonal BN (h-BN) – Soft, lubricious, thermally conductive

✔Cubic BN (c-BN) – 2nd hardest material after diamond

✔Wurtzite BN (w-BN) – Ultra-high hardness (rare)

| Property | h-BN | c-BN |

| Hardness (Mohs) | 1-2 (graphite-like) | ~9.5 (near diamond) |

| Thermal Conductivity | 30-60 W/mK (in-plane) | 13 W/mK (like diamond) |

| Max Temp (Air) | 900°C (oxidizes above) | 1,400°C (stable) |

| Electrical Behavior | Insulator | Insulator |

Competitive Advantages:

✓ Non-reactive with molten metals (unlike graphite)

✓ Chemically inert (resists acids/alkalis)

✓ Anisotropic thermal conductivity (h-BN)

✓ Machinable into complex shapes (h-BN)

Applications include:

- Heat Sinks: Dissipate heat in electronic systems, ensuring reliable performance.

- Nozzles: Used in rocket engines for their resistance to thermal and chemical degradation.

- High-Temperature Insulators: Protect sensitive components in extreme environments.

BN’s versatility comes at a high cost, but its performance in niche applications justifies its use.

Explore our optimized technical ceramic products.

Technical Ceramics in Aerospace: Critical Applications

Technical ceramics are integral to several critical aerospace applications, enabling advancements in performance, safety, and efficiency. Their ability to operate in extreme conditions addresses challenges that traditional materials struggle to overcome. Key applications include:

1. Turbine Engine Components

Key Ceramics: Si₃N₄ (Silicon Nitride), SiC (Silicon Carbide)

Applications:

- Blades & Vanes – Withstand 1,500°C+ in jet engines (replacing nickel superalloys)

- Combustor Liners – Reduce cooling needs with SiC’s thermal resistance

- Bearings – Si₃N₄’s self-lubricating properties prevent seizure at high RPMs

Impact:

✔ 20%+ fuel efficiency gains in next-gen engines (e.g., GE’s CERAMIC MATRIX COMPOSITE turbines)

✔ 50% weight reduction vs. metal alternatives

2. Thermal Protection Systems

Key Ceramics: ZrO₂ (Zirconia), Al₂O₃ (Alumina), Ultra-High-Temperature Ceramics (UHTCs)

Applications:

- Heat Shields – ZrO₂ coatings on re-entry vehicles (e.g., SpaceX Dragon)

- Leading Edges – UHTCs like ZrB₂/SiC for hypersonic vehicles (>2,500°C)

- Rocket Nozzles – Al₂O₃-SiC composites resist plasma erosion

Impact:

✔ Enable Mach 5+ hypersonic flight

✔ Survive atmospheric re-entry temperatures (~1,650°C)

3. Avionics & Sensors

Key Ceramics: AlN (Aluminum Nitride), LTCC (Low-Temperature Co-fired Ceramics)

Applications:

- Radar Transparent Radomes – BN composites for missile guidance systems

- Thermal Management – AlN substrates cool high-power satellite electronics

- Oxygen Sensors – ZrO₂-based lambda sensors optimize combustion

Impact:

✔ 30% better heat dissipation than traditional PCB materials

✔ Withstand ionizing radiation in space environments

4. Lightweight Structural Components

Key Ceramics: Si₃N₄, Al₂O₃, CMCs (Ceramic Matrix Composites)

Applications:

- Airframe Brackets – Si₃N₄ reduces weight while maintaining strength

- CMCs in Fan Blades – GE’s LEAP engine uses CMCs for 30% weight savings

- Satellite Mirrors – Zero-porosity SiC for dimensional stability in orbit

Impact:

✔ 40% lighter than titanium with comparable strength

✔ Zero thermal expansion is critical for space optics

5. Space Exploration Systems

Key Ceramics: SiC, Al₂O₃, Porous Ceramics

Applications:

- Mars Rover Components – SiC bearings survive dust storms

- Spacecraft Insulation – Al₂O₃-SiO₂ aerogels for cryogenic tanks

- Meteoroid Shields – Porous ceramic Whipple shields on ISS

Impact:

✔ Operate in -150°C to +1,500°C lunar/Martian environments

✔ Radiation shielding for deep-space missions

Why Aerospace Chooses Ceramics Over Metals?

| Challenge | Ceramic Solution | Metal Limitation |

| High Temperatures | SiC operates at 1,650°C+ | Superalloys soften above 1,200°C |

| Weight Reduction | Si₃N₄: 60% lighter than steel | Heavy structural penalties |

| Corrosion Resistance | Al₂O₃/ZrO₂ inert to rocket fuels | Titanium reacts with some propellants |

| Fatigue Resistance | CMCs resist microcrack propagation | Metal fatigue limits the lifecycle |

Request a custom quote for high-quality technical ceramic products.

Challenges and Future Trends

Despite their advantages, technical ceramics face significant challenges in aerospace applications. Manufacturing ceramics is costly due to the need for high-purity raw materials and complex processes like sintering or chemical vapor deposition. Their brittleness requires precise engineering to prevent catastrophic failure, and large-scale production remains a hurdle.

Innovations are addressing these challenges:

- Additive Manufacturing: 3D printing of ceramics allows for complex geometries, reducing waste and production costs. For example, SiC components can now be printed with intricate internal cooling channels.

- Nanotechnology: Incorporating nanoparticles enhances ceramic toughness and thermal resistance, improving reliability.

- Hybrid Materials: Ceramic matrix composites (CMCs) combine ceramics with fibers, offering improved toughness and scalability.

Future trends point to increased use of ceramics in hypersonic vehicles, which require materials capable of withstanding temperatures above 2,500°C. Additionally, sustainable aerospace solutions, such as electric propulsion systems, may leverage ceramics for their lightweight and durable properties. Continued investment in research and manufacturing will unlock new possibilities.

At Advanced Ceramics Hub, we supply optimized-grade technical ceramic products that comply with ASTM and ISO standards, ensuring outstanding quality and reliability.

Conclusion

Technical ceramics are a game-changer in aerospace, offering solutions to the industry’s most demanding challenges. From silicon carbide’s heat resistance to boron nitride’s thermal conductivity, the top five high-performance ceramics—SiC, Al₂O₃, ZrO₂, Si₃N₄, and BN—enable cutting-edge applications in engines, thermal protection, structures, and electronics. Their ability to perform in extreme conditions while reducing weight and improving efficiency is driving their adoption across aviation and space exploration.

As challenges like high costs and brittleness are addressed through innovations like additive manufacturing and nanotechnology, the future of technical ceramics looks promising. Their role in hypersonic flight and sustainable aerospace technologies underscores the need for continued research and investment. By embracing these materials, the aerospace industry can soar to new heights, achieving unprecedented performance and reliability.

For top-quality technical ceramic products, Advanced Ceramics Hub provides tailored solutions and precision machining techniques for various applications.

Looking for premium technical ceramic products? Contact us today!