Impact of Pore Size on Alumina Foam’s Properties

Alumina foam is a highly porous ceramic material used in filtration, insulation, catalyst support, and biomedical applications. One of its most critical design parameters is pore size. Whether the application demands high mechanical strength or optimized fluid flow, the pore size in alumina foam can make or break performance. This article explores how pore size impacts the physical, thermal, and mechanical properties of alumina foam. It includes quantitative comparisons, tables, and lists to guide engineers and researchers in selecting the right pore size for specific applications—and how alumina foam compares to other ceramic materials like silicon carbide, mullite, and zirconia.

At Advanced Ceramic Hub, we specialize in high-quality alumina foam products, ensuring optimal performance for industrial and scientific applications.

What Is Alumina Foam and How Is Its Pore Size Controlled?

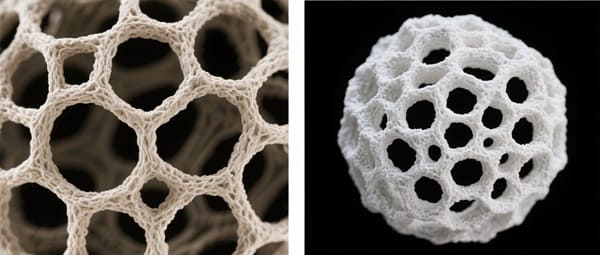

Alumina foam is a lightweight, high-temperature ceramic made primarily of aluminum oxide (Al₂O₃). Its porous structure results from various manufacturing methods, each allowing different degrees of control over pore size and distribution. These techniques determine the foam’s mechanical behavior, permeability, and thermal conductivity.

Common Manufacturing Methods and Pore Size Ranges in Alumina Foam:

| Manufacturing Method | Description | Pore Size Range (µm) |

| Polymer Sponge Replication | Coating foam templates, then firing | 100–1000 |

| Direct Foaming | Gas bubbles form during slurry solidification | 50–500 |

| Freeze Casting | Ice templating results in aligned pores | 5–200 |

| 3D Printing | Layer-by-layer deposition with tailored porosity | Custom (10–1000) |

Controlling pore size begins with choosing the right method. For instance, freeze casting offers the best control for aligned small pores, while replication methods are more suitable for bulk filters needing large pores.

Explore our high-quality alumina foam products.

How Does Pore Size Affect the Mechanical Strength of Alumina Foam?

Mechanical strength in alumina foam is closely tied to its porosity and pore size. As pore size increases, the amount of material forming the solid struts decreases, weakening the structure. However, overly small pores can introduce brittleness, especially in dynamic load scenarios.

Relationship Between Pore Size and Mechanical Strength in Alumina Foam:

| Average Pore Size (µm) | Compressive Strength (MPa) | Flexural Strength (MPa) |

| < 100 | 3.5–8 | 1.0–1.5 |

| 100–300 | 1.5–3 | 0.4–0.8 |

| > 500 | < 1.0 | < 0.3 |

Selecting pore size for mechanical performance is a tradeoff. Smaller pores offer higher strength but limit permeability. Large pores favor flow but compromise structure, making them ideal for filters but not for load-bearing roles.

How Does Pore Size Impact the Thermal Conductivity of Alumina Foam?

Thermal conductivity in alumina foam decreases significantly as pore size—and hence porosity—increases. Air within the pores acts as an insulator, lowering effective conductivity. This makes alumina foam ideal for thermal barrier applications.

Thermal Conductivity vs. Pore Size in Alumina Foam:

| Porosity (%) | Avg. Pore Size (µm) | Thermal Conductivity (W/m·K) |

| 60 | 50 | 5–7 |

| 80 | 200 | 2–3 |

| 90 | 500+ | < 1 |

While alumina’s base thermal conductivity is ~30 W/m·K, introducing high porosity and larger pores can drop that below 1 W/m·K. Engineers must weigh this against mechanical requirements.

How Does Pore Size Influence Filtration and Permeability in Alumina Foam?

Permeability is essential in applications like gas and liquid filtration. Pore size directly affects flow rates—larger pores yield higher permeability but lower capture efficiency.

Pore Size vs. Permeability and Filtration Use Cases:

| Pore Size (µm) | Air Permeability (Darcy) | Suitable Applications |

| < 100 | < 0.1 | Catalyst beds, fine filtration |

| 100–300 | 0.1–1.0 | Oil/gas filters, heat exchangers |

| > 500 | > 1.0 | Dust filters, high-flow systems |

For filtering fine particles, smaller pores are necessary despite a higher pressure drop. For high-throughput or coarse filtration, larger pores are preferred.

How Does Alumina Foam’s Pore Size Affect Surface Area for Catalysis?

Surface area is critical in catalytic applications. Smaller pores increase the internal surface area, improving reactivity and adsorption capacity. However, very fine pores may restrict flow and mass transfer.

BET Surface Area vs. Pore Size in Alumina Foam:

| Pore Size (µm) | BET Surface Area (m²/g) | Typical Use |

| 10–50 | 2.0–5.0 | Catalysis, adsorbents |

| 100–300 | 0.5–2.0 | Air/water filtration |

| > 500 | < 0.5 | Structural insulation, filler cores |

Choosing the right pore size balances surface area and accessibility. For catalyst support, medium to small pores offer the best results.

How Does Alumina Foam Compare to Other Ceramic Foams in Terms of Pore Size Effects?

Alumina foam is just one type of ceramic foam. Other materials like silicon carbide, zirconia, and mullite exhibit different behavior concerning pore size, especially in high-temperature or chemically aggressive environments.

Alumina Foam vs. Other Ceramic Foams:

| Material | Max Temp (°C) | Strength | Surface Area | Thermal Conductivity | Cost |

| Alumina Foam | 1600 | Medium | High | Low (1–5 W/m·K) | Low |

| Silicon Carbide | 1500 | High | Medium | Moderate (10–20) | Medium |

| Zirconia Foam | 2200 | Low | Medium | Very Low (<1 W/m·K) | High |

| Mullite Foam | 1400 | Medium | Medium | Low | Low |

Alumina foam offers an excellent cost-to-performance ratio, especially when moderate strength and high thermal resistance are needed.

Request a custom quote for alumina foam products.

How Does Alumina Foam Pore Size Compare to Metal and Polymer Foams?

Compared to metal and polymer foams, alumina foam offers superior chemical and thermal stability but lower toughness. Pore size effects differ across materials due to their base mechanical and thermal properties.

Cross-Material Comparison of Foams:

| Material Type | Pore Size (µm) | Thermal Conductivity | Strength | Stability |

| Alumina Foam | 10–1000 | 1–5 W/m·K | Medium | Excellent |

| Metal Foam | 100–2000 | 10–200 W/m·K | High | Moderate (oxidizes) |

| Polymer Foam | 100–5000 | < 0.1 W/m·K | Low | Poor (melts/burns) |

Alumina foam stands out where high temperature, corrosion resistance, and tailored pore size matter.

What Are the Future Trends in Pore Size Control in Alumina Foam?

New technologies like additive manufacturing and AI-driven design are enabling unprecedented control over pore size and distribution in alumina foam. These developments support more efficient and application-specific ceramic materials.

Emerging Techniques for Pore Size Control in Alumina Foam:

- 3D Printing: Enables custom-designed pores and complex geometries

- Hierarchical Pore Structures: Combine micro- and macro-pores in one foam

- AI-Based Sintering Models: Predict shrinkage and pore evolution

- Functional Coatings: Modify surface activity inside pores

- Hybrid Ceramic Composites: Incorporate tailored phases for enhanced function

These trends allow engineers to design “smart” foams that balance strength, porosity, and chemical performance.

FAQ

| Question | Answer |

| Can I customize pore size for my application? | Yes, via controlled fabrication techniques. |

| Does pore size affect foam color or weight? | Indirectly, by altering density and light scatter. |

| Is smaller always better? | Not always; tiny pores reduce flow and may crack more easily. |

| Can alumina foam be used in water filters? | Yes, especially with 100–300 µm pores. |

| Is pore size uniform throughout the foam? | Depends on the production method used. |

Conclusion

Pore size is one of the most defining characteristics of alumina foam. It affects mechanical strength, thermal insulation, permeability, and surface area. By carefully selecting pore size based on application—whether filtration, insulation, or catalysis—engineers can optimize the performance of alumina foam. Compared to other ceramics, alumina foam offers a balanced profile of affordability, temperature resistance, and tunable porosity, making it a versatile and scalable solution across multiple industries. With future advancements in manufacturing, precise pore engineering will unlock even greater functionality in next-generation ceramic designs.

Looking for high-quality ceramic foam products? Contact us today!