Why Alumina Boats Are Essential for Metallurgical Processes?

Metallurgical processes are fundamental in producing and refining metals, which are critical for various industries, including automotive, aerospace, and construction. These processes typically involve heating, melting, and shaping metals into usable forms. Alumina boats are essential tools in these processes, primarily used for holding molten metals during heating, cooling, or electrochemical reactions. This article will delve into why Alumina boats are indispensable in metallurgy, focusing on their properties, functions, and advantages.

At Advanced Ceramics Hub, we specialize in high-quality alumina products, ensuring optimal performance for industrial and scientific applications.

Overview of Alumina Boats in Metallurgy

What Are Alumina Boats?

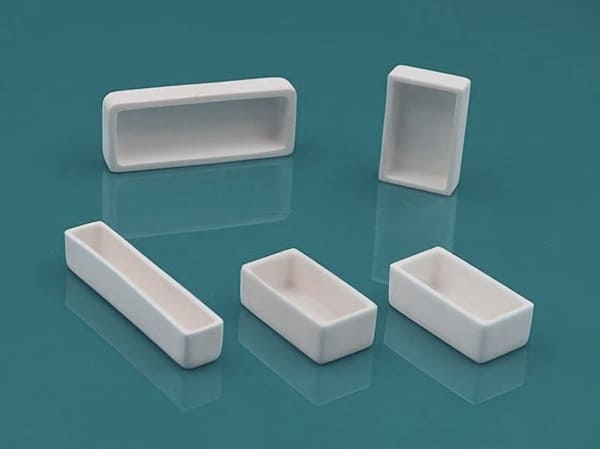

Alumina boats are high-purity ceramic containers made from aluminum oxide (Al₂O₃), designed for high-temperature material processing in industries like metallurgy, semiconductors, and crystal growth. They offer exceptional thermal stability, chemical resistance, and durability under extreme conditions.

Key Properties of Alumina Boats

| Property | Alumina (99.5% purity) | Comparison (Quartz/Mullite) |

| Max Operating Temp | 1700°C | Quartz: 1200°C |

| Thermal Shock Resistance | ΔT = 300°C | Mullite: ΔT = 200°C |

| Chemical Resistance | Inert to acids/bases (except HF) | Graphite reacts with oxygen |

| Dielectric Strength | 15 kV/mm | Quartz: 8 kV/mm |

Types of Alumina Boats

| Type | Purity | Use Case |

| Standard | 95% Al₂O₃ | General-purpose sintering |

| High-Purity | 99.5%+ | Semiconductor/CVD processes |

| Recrystallized | 99.8% | Single-crystal growth |

Manufacturing of Alumina Boats

Alumina boats are high-purity ceramic containers made from aluminum oxide (Al₂O₃), used in high-temperature applications like semiconductor processing and metallurgy. Their production involves powder preparation, forming, sintering, and precision machining for thermal stability (>1700°C), chemical inertness, and strength. Techniques like injection molding allow complex shapes, while sintering aids (e.g., MgO) enhance microstructure.

Key Manufacturing Steps:

✅Powder Preparation:

- Milling to submicron particles (0.5–1 µm)

- Mixing with binders (e.g., PVA)

✅Forming:

- Dry pressing (simple shapes)

- Slip casting (complex designs)

- Injection molding (high precision)

✅Sintering:

- Debinding (400–600°C)

- High-temperature firing (1600–1800°C)

✅Post-Processing:

- Diamond machining (±0.1 mm tolerance)

- Optional coatings (Y₂O₃/SiC)

Performance Comparison by Manufacturing Method:

| Method | Density (g/cm³) | Surface Finish | Best For |

| Dry Pressing | 3.6–3.8 | Moderate | Standard crucibles |

| Slip Casting | 3.4–3.6 | Rough | Large/custom boats |

| Injection Molding | 3.8–3.9 | Excellent | Semiconductor components |

Note: Density and finish directly correlate with thermal shock resistance and contamination risk.

Alumina boats are vital to metallurgical processes, offering unmatched durability and performance in extreme conditions. Their unique properties make them indispensable for high-precision metal processing in 2025. Here are five key reasons why alumina boats are essential:

Looking for top-quality alumina boats? Explore Advanced Ceramics Hub’s selection.

Reason 1: Superior High-Temperature Resistance

Alumina boats are crucial in metallurgical processes, withstanding temperatures over 1500°C. With a melting point of 2072°C and stability up to 1800°C, they outperform alternatives like quartz (1000°C) and graphite (oxidizes at 500°C). This makes them ideal for high-temperature applications like vacuum induction melting of titanium alloys, where they maintain structural integrity above 1600°C. Their low thermal conductivity also improves energy efficiency. While zirconia boats can handle slightly higher temperatures (~2200°C), alumina boats offer a cost-effective balance of performance and affordability.

| Property | Alumina Boat (99.5% Al₂O₃) | Competing Materials |

| Max Operating Temp | 1700°C (short-term) | Quartz: 1200°C / Graphite: 3000°C (but oxidizes) |

| Continuous Use Temp | 1600°C | Quartz: 1100°C / Graphite: 2200°C (in inert gas) |

| Thermal Shock Resistance | ΔT = 300°C | Quartz: ΔT = 150°C / Graphite: ΔT = 500°C (but brittle) |

| Melting Point | 2072°C (theoretical) | Quartz: 1670°C / Graphite: Sublimes at 3650°C |

| Thermal Expansion Coefficient | 8.1 × 10⁻⁶/K (20-1000°C) | Quartz: 0.55 × 10⁻⁶/K / Graphite: 4-8 × 10⁻⁶/K (anisotropic) |

| Oxidation Resistance at High Temperatures | Excellent (forms protective oxide layer) | Quartz: Good (but devitrifies above 1100°C) / Graphite: Poor (oxidizes rapidly above 500°C in air) |

- Resists molten aluminum (660°C) and copper (1085°C) corrosion.

- Longer lifespan than graphite in oxidizing atmospheres.

Reason 2: Exceptional Chemical Inertness

Alumina boats are essential in metallurgical processes due to their chemical inertness, maintaining the purity of molten metals. Composed of high-purity Al₂O₃ (99.5–99.9%), they exhibit minimal reactivity with metals like iron, nickel, aluminum, and precious metals, as well as slags and fluxes. This prevents contamination, crucial in industries like electronics. For example, alumina boats preserve the purity of platinum during refining for catalytic converters. Unlike graphite or silica boats, alumina boats resist chemical reactions, extending lifespan and reducing contamination risks. Their resistance to acids, bases, and molten salts further enhances their reliability in demanding environments.

- Non-reactive with most molten metals and alloys.

- Resistant to acidic and basic slags.

- Minimal diffusion of boat material into samples.

- Stable against molten salts and fluxes.

| Chemical Resistance Property | Alumina Boat (99.5% Al₂O₃) | Quartz (SiO₂) | Graphite (C) |

| Acid Resistance | ✔️ Resistant to most acids (HCl, HNO₃, H₂SO₄) ✖️ Attacked by HF and hot H₃PO₄ | ✔️ Resistant to weak alkalis ✖️ Slowly attacked by strong bases (NaOH, KOH) at high temperatures | ✔️ Resistant to non-oxidizing acids ✖️ Reacts with hot HNO₃, H₂SO₄ |

| Alkali Resistance | ✔️ Resistant to weak alkalis ✖️ Slowly attacked by strong bases (NaOH, KOH) at high temps | ✖️ Dissolves in strong alkalis (NaOH, KOH) | ✔️ Resistant to alkalis |

| Molten Metal Resistance | ✔️ Highly resistant to most molten metals (Al, Cu, Ag) ✖️ Reacts with Ti, Zr, and reactive metals | ✖️ Reacts with molten metals (e.g., Al, alkali metals) | ✖️ Forms carbides with Fe, Ni, Co, and other metals |

| Halogen & Reactive Gas Resistance | ✔️ Resistant to Cl₂, F₂ (at moderate temps) ✖️ Reacts with F₂ at high temps | ✖️ Reacts with F₂ and Cl₂ at high temps | ✖️ Reacts violently with F₂, Cl₂, and O₂ |

| Oxidation Resistance | ✔️ Fully oxidized (no further oxidation) | ✔️ Good below 1100°C (then devitrifies) | ✖️ Oxidizes rapidly in air above 500°C |

Why Alumina Excels in Chemical Inertness?

- Stable Oxide Structure – Al₂O₃ is already in its highest oxidation state, preventing further corrosion.

- Wide pH Stability – Performs well in both acidic and mildly alkaline environments (unlike quartz, which dissolves in strong bases).

- No Carbide Formation – Unlike graphite, alumina does not react with molten metals to form carbides.

- Superior Halogen Resistance – More stable than quartz and graphite in chlorine/fluorine environments (except at very high temps).

Reason 3: High Mechanical Strength and Durability

Alumina boats are highly durable, with compressive strengths between 2000 and 3000 MPa, making them ideal for demanding metallurgical processes. Their low coefficient of thermal expansion (~8×10⁻⁶/°C) ensures resistance to thermal shock, preventing cracking during rapid temperature changes. Unlike silica (500 MPa) or graphite boats (100 MPa), which degrade quickly, alumina boats have a long lifespan and can endure multiple cycles without significant wear. In steel production, they maintain structural integrity in induction furnaces, reducing downtime and replacement costs. This durability aligns with industry trends toward sustainability and waste reduction. Below is a comparison of the mechanical properties of crucible materials.

| Mechanical Property | Alumina Boat (99.5% Al₂O₃) | Quartz (SiO₂) | Graphite (C) |

| Flexural Strength (MPa) | 300–400 MPa (high stability) | 50–70 MPa (brittle) | 10–30 MPa (weak in tension) |

| Compressive Strength (MPa) | 2000–3000 MPa (extremely hard) | ~1100 MPa | 20–100 MPa (soft, flakes easily) |

| Hardness (Mohs/Vickers) | 9 Mohs / 1500–2000 HV | 7 Mohs / ~800 HV | 1–2 Mohs / Very soft |

| Wear Resistance | ✔️ Excellent (resists abrasion) | ✖️ Poor (scratches easily) | ✖️ Poor (erodes quickly) |

| Thermal Cycling Durability | ✔️ High (resists cracking) | ✖️ Low (prone to devitrification) | ✔️ Good (but oxidizes) |

| Structural Stability | ✔️ Maintains shape at high temps | ✖️ Warps/softens >1100°C | ✔️ Stable but weakens in air |

Why Alumina Excels in Mechanical Strength?

- High Hardness & Wear Resistance – Alumina is nearly as hard as sapphire (9 Mohs), making it resistant to scratches and abrasion.

- Outstanding Compressive Strength – Withstands heavy loads (2000+ MPa), unlike graphite, which crushes easily.

- Retains Shape at High Temperatures – Unlike quartz, which softens and warps above 1100°C, alumina remains rigid up to 1600°C.

- Thermal Cycling Performance – Handles rapid temperature changes (ΔT = 300°C) better than quartz, which cracks under thermal shock.

Explore our optimized alumina boats.

Reason 4: Versatility Across Metallurgical Applications

Alumina boats are essential in both laboratory and industrial metallurgical processes, including melting, alloying, sintering, calcination, and heat treatment. Their customizable sizes, shapes, and high-purity composition make them suitable for various metals, such as steel, aluminum, copper, gold, silver, and advanced alloys. In powder metallurgy, they ensure uniform heating and minimal contamination during sintering, while in industrial settings, they support operations like aluminum smelting. Their chemical and thermal stability enables use in both oxidizing and reducing atmospheres, unlike graphite boats, which are limited to non-oxidative environments. This versatility streamlines operations, increasing efficiency in the fast-paced metallurgical industry.

- Vacuum arc melting for superalloys in aerospace.

- Sintering of metal powders for 3D printing.

- Precious metal refining for jewelry and electronics.

- Heat treatment of stainless steel components.

Comparison of Metallurgical Performance:

| Application | Alumina Boat (99.5% Al₂O₃) | Quartz (SiO₂) | Graphite (C) |

| Metal Melting & Casting | ✔️ Excellent for Al, Cu, Ag, Au, Pt (no reaction) ✖️ Unsuitable for Ti, Zr, reactive metals | ✖️ Reacts with molten Al, alkali metals | ✔️ High-temp capable but forms carbides (Fe, Ni, Co) |

| Heat Treatment/Sintering | ✔️ Stable up to 1600°C (no deformation) | ✖️ Softens >1100°C | ✔️ Good in inert gas, but oxidizes in air |

| Powder Metallurgy | ✔️ Chemically inert, no contamination | ✖️ Can introduce Si impurities | ✖️ Carbon contamination risk |

| Crystal Growth (Semiconductors) | ✔️ Ultra-pure, no doping | ✖️ Si contamination in GaAs, SiC growth | ✖️ Carbon pickup in Si, GaN processes |

| Salt Bath & Flux Handling | ✔️ Resists molten salts (e.g., chlorides, fluorides) | ✖️ Attacked by halide salts | ✖️ Reactive with oxidizing fluxes |

Why Alumina is the Preferred Choice in Metallurgy?

1. Broad Metal Compatibility

- Does not react with most non-reactive metals (Cu, Ag, Au, Pt) and even molten aluminum.

- Unlike graphite, it does not form carbides with transition metals (Fe, Ni, Co).

2. High-Temperature Structural Integrity

- Maintains rigidity up to 1600°C, whereas quartz softens and graphite erodes in oxidizing environments.

3. No Contamination Risk

- Critical for semiconductor and precision alloy processing, where even trace impurities (Si from quartz, C from graphite) can ruin material properties.

4. Corrosion Resistance in Salt & Flux Environments

- Withstands molten chlorides/fluorides (e.g., in aluminum refining), unlike quartz, which degrades.

Reason 5: Cost-Effectiveness and Longevity

Alumina boats, despite their higher initial cost, offer long-term savings due to their durability and longevity. They last 50–100 cycles in high-temperature furnaces, far outlasting silica (5–10 cycles) and graphite boats (10–20 cycles). This reduces replacement frequency, downtime, and maintenance costs, making them ideal for high-throughput operations like steel and aluminum smelting. In induction furnaces, alumina boats lower the cost per cycle to $1–2, compared to $2–3 for silica. Their resistance to contamination ensures high-purity outputs, meeting stringent standards like those for aerospace alloys. This durability translates to significant savings for the metallurgical industry.

| Economic Factor | Alumina Boat | Quartz Boat | Graphite Boat |

| Initial Cost | $$$ (Higher) | $$ (Moderate) | $ (Lowest) |

| Lifespan | 2-5+ years | 6-18 months | 3-12 months* |

| Replacement Frequency | Low | Moderate | High |

| Failure Modes | Minimal (cracking only under extreme abuse) | Thermal shock failure, devitrification | Oxidation, crumbling, carbide formation |

| Downtime Costs | Lowest | Moderate | Highest |

| Total Cost of Ownership | Most Economical | Higher long-term | Highest long-term |

Request a custom quote for high-quality alumina boats.

Comparison with Alternative Materials

Alumina boats offer an optimal balance for metallurgical processes, outperforming alternatives like graphite, silica, and zirconia. Graphite boats ($5–20) are reactive and unsuitable for high-purity applications, while silica boats ($10–30) are limited to 1000°C and prone to contamination. Zirconia boats ($100–500) are expensive and used only for niche applications. Alumina boats, with high-temperature resistance (up to 1800°C), chemical inertness, and moderate cost ($50–200), are ideal for most applications. Their long lifespan and minimal maintenance make them the preferred choice for industries like aerospace and electronics.

| Property | Alumina (Al₂O₃) | Graphite | Silica (SiO₂) | Zirconia (ZrO₂) |

| Max Operating Temperature (°C) | 1800 | ~500 (in air) | ~1000 | 2200 |

| Melting Point (°C) | 2072 | ~3600 (sublimes) | 1713 | 2715 |

| Thermal Conductivity (W/m·K) | 20–30 (at 25°C) | 100–150 (high) | 1.4–2.0 (low) | 2–3 (very low) |

| Coefficient of Thermal Expansion (10⁻⁶/°C) | ~8 | 2–6 | ~0.5 | ~10 |

| Thermal Shock Resistance | High | Low | Moderate | High |

| Compressive Strength (MPa) | 2000–3000 | ~100 | ~500 | ~2000 |

| Flexural Strength (MPa) | 300–400 | 20–50 | 50–100 | 900–1200 |

| Hardness (Mohs) | 9 | 1–2 | 7 | 8–8.5 |

| Density (g/cm³) | 3.9 | 1.8–2.2 | 2.2 | 5.6–6.0 |

| Chemical Inertness | High (inert to most metals, slags) | Low (reactive with O₂, metals) | Moderate (reacts with alkaline slags) | High (similar to alumina) |

| Lifespan (Cycles) | 50–100 | 10–20 | 5–10 | 50–100 |

| Best Metallurgical Use | High-purity metallurgy (e.g., titanium alloys, precious metals) | Reducing environments (e.g., carbon-rich processes) | Low-temperature processes (e.g., glass melting) | Niche high-temperature applications (e.g., ultra-high-temp ceramics) |

At Advanced Ceramics Hub, we supply high-performance alumina boats that comply with ASTM and ISO standards, ensuring outstanding quality and reliability.

Future Trends and Innovations

The future of alumina boats in metallurgical processes is marked by innovations like Zirconia Toughened Alumina (ZTA), combining alumina’s stability with zirconia’s toughness for improved durability in applications like rare earth metal recycling. Additive manufacturing (3D printing) is enabling the production of customized alumina boats that optimize heat distribution and metal flow, enhancing yield and quality. Green metallurgy is also driving research into recyclable alumina boats and eco-friendly production methods. These advancements suggest that alumina boats will continue to play a key role in sustainable, high-precision metallurgy.

| Trend | Description | Impact | Example Application |

| ZTA Formulations | Alumina with zirconia for toughness | Enhanced durability | Rare earth recycling |

| 3D Printing | Custom shapes for efficiency | Improved yield | Continuous casting |

| Sustainable Production | Recyclable boats, eco-friendly methods | Lower environmental impact | Green metallurgy |

| New Applications | Aerospace, renewable energy | Expanded markets | Solar panel processing |

Alumina boats are essential in metallurgical processes, offering high-temperature resistance, chemical inertness, mechanical strength, and cost-effectiveness. With a temperature tolerance of up to 1800°C, they ensure high-purity outputs for industries like aerospace, automotive, and electronics. Their durability (50–100 cycles) reduces costs and downtime, while their adaptability supports various applications, from alloy testing to smelting. Innovations like ZTA formulations and 3D printing are enhancing alumina boats’ role in future advancements, particularly in titanium alloy production and precious metal refining. Embracing alumina boats boosts process reliability, reduces costs, and meets the evolving demands of modern metal processing.

For top-quality alumina products, Advanced Ceramics Hub provides tailored solutions for various applications.

Looking for premium alumina boats? Contact us today!