Alumina Spherical Powder

Alumina Spherical Powder

Purity: 99.9%-99.999%

Brands: BAK Series, Top Cut Series, BAH Series, BAM Series

Alumina Spherical Powder is a high-performance inorganic material with high purity, fine and uniform particle size. It is widely used for thermal management, polishing, and as a filler material. As a leading supplier and manufacturer of premium alumina products, we can supply high-quality alumina powders with various specifications and competitive prices, offering customized solutions to meet specific requirements.

Or email us at sales@heegermaterials.com.Alumina Spherical Powder Data Sheet

| Reference Code: | HM1967 |

| Purity: | 99.9%-99.999% |

| Morphology: | Spherical |

| Appearance: | White Powder |

| Series: | BAK Series, Top Cut Series, BAH Series, and BAM Series |

Alumina Spherical Powder

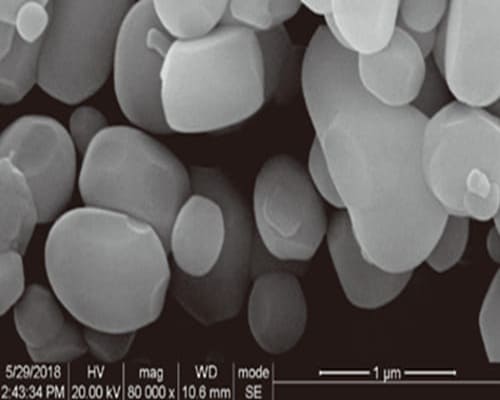

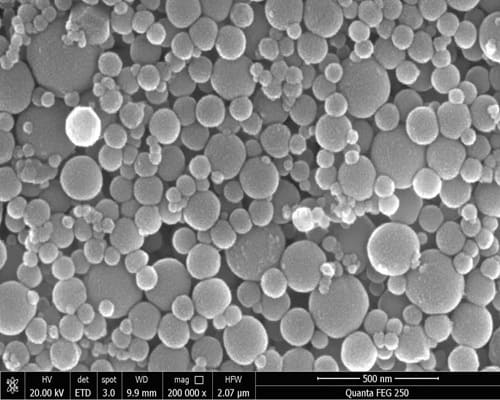

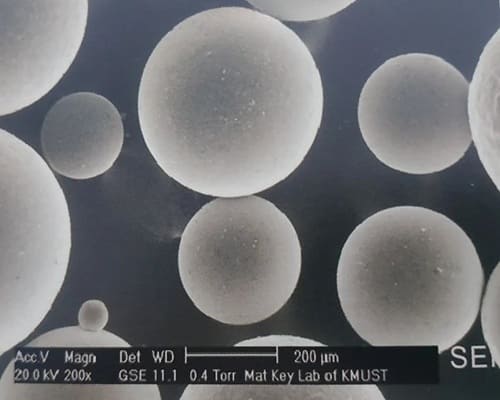

Alumina Spherical Powder is a white powder with a purity of 99.9% to 99.999%. It has a high α-phase content, excellent stability, high crystallinity, and uniform particle size. The spherical shape ensures a uniform distribution and improves its flowability and packing density, making it has excellent thermal conductivity. Advanced Ceramics Hub can supply high-quality alumina (Al2O3) spherical powder in the BAK series, Top Cut Series, BAH Series, and BAM Series to meet diverse industrial and research requirements.

Alumina Spherical Powder BAK Series Specifications

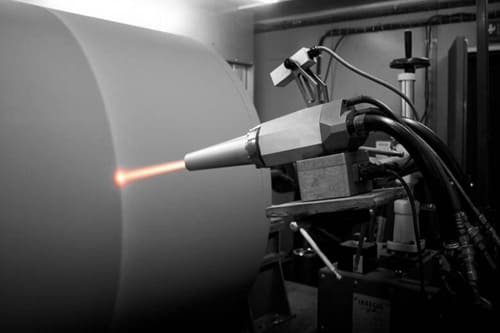

The BAK series is manufactured by calcining ordinary irregular Al2O3 using a high-temperature melting and spheroidizing injection method, followed by purification, screening, and other processes. The BAK series is widely used as a thermally conductive interface material, thermally conductive engineering plastic, and thermally conductive filler for aluminum-based copper-clad laminates, owing to its excellent thermal conductivity and fluidity.

| Properties | Unit | BAK-1 | BAK-2 | BAK-5 | BAK-10 | BAK-15 | BAK-20 | BAK-30 | BAK-40 | BAK-70 | BAK-90 | BAK-120 | |

| Particle Size | D10 | μm | 0.58 | 0.69 | 2.54 | 4.18 | 7.03 | 10.5 | 16.88 | 23.77 | 44.32 | 55.23 | 90.95 |

| D50 | μm | 1.03 | 2.18 | 5.52 | 10.03 | 15.11 | 20.8 | 30.52 | 41.54 | 71.54 | 87.96 | 122.39 | |

| D90 | μm | 2.14 | 5.24 | 9.09 | 18.46 | 24.06 | 37.24 | 48.87 | 66.44 | 106.5 | 134.92 | 172.72 | |

| Specific Surface Area | m2/g | 1.69 | 1.27 | 0.36 | 0.17 | 0.14 | 0.11 | 0.1 | 0.07 | 0.05 | 0.06 | 0.06 | |

| Electricity Conductivity | μS/cm | 6.07 | 5.40 | 5.65 | 4.05 | 1.83 | 6.87 | 7.95 | 4.65 | 6.18 | 8.15 | 2.6 | |

| PH Value | — | 7.53 | 7.79 | 7.7 | 7.41 | 7.37 | 7.62 | 7.39 | 7.31 | 7.42 | 7.3 | 7.44 | |

| Moisture | % | 0.05 | 0.03 | 0.03 | 0.03 | 0.03 | 0.03 | 0.03 | 0.03 | 0.05 | 0.03 | 0.03 | |

| True Density | g/cm3 | 3.71 | 3.71 | 3.74 | 3.76 | 3.86 | 3.79 | 3.75 | 3.81 | 3.87 | 3.88 | 3.81 | |

| Spheroidization Rate | % | 96 | 98 | 98 | 98 | 96 | 96 | 98 | 96 | 96 | 95 | 96 | |

| Chemical Composition | Al2O3 | % | 99.93 | 99.94 | 99.93 | 99.94 | 99.93 | 99.94 | 99.94 | 99.94 | 99.94 | 99.94 | 99.94 |

| SiO2 | ppm | 445 | 373 | 424 | 358 | 430 | 352 | 333 | 349 | 342 | 330 | 359 | |

| Fe2O3 | ppm | 152 | 120 | 176 | 136 | 158 | 144 | 161 | 148 | 158 | 164 | 133 | |

| Na2O | ppm | 103 | 107 | 100 | 106 | 112 | 104 | 106 | 103 | 100 | 106 | 108 | |

Alumina Spherical Powder Top Cut Series Specifications

The Top Cut Series is an optimized version of the BAK series, featuring high sphericity, high filling rate, high thermal conductivity, and a narrow particle size distribution. It is widely used in applications such as epoxy molding compounds, thermal interface materials, thermally conductive engineering plastics, and thermally conductive substrates.

| Product | Particle Size(μm) | Specific Surface Area | Electricity Conductivity | PH | Moisture | True Density | Spheroidization Rate | |||

| D10 | D50 | D90 | D97 | ㎡ /g | μS/cm | – | % | g/cm³ | % | |

| BAK-5-25C | 3.25 | 5.77 | 10.36 | 15.6 | 0.38 | 2.64 | 6.79 | 0.03 | 3.7 | 96 |

| BAK-10-35C | 4.52 | 9.32 | 18.11 | 22.1 | 0.22 | 5.81 | 7.33 | 0.02 | 3.82 | 96 |

| BAK-15-45C | 9.28 | 16.81 | 27.68 | 33.88 | 0.12 | 3.77 | 6.8 | 0.03 | 3.78 | 97 |

| BAK-30-75C | 16.16 | 31.78 | 52.47 | 60.87 | 0.09 | 3.77 | 7.05 | 0.03 | 3.8 | 96 |

| BAK-40-75C | 21.98 | 39.63 | 63.49 | 75.93 | 0.09 | 4.68 | 6.82 | 0.03 | 3.79 | 96 |

| BAK-70-120C | 51.54 | 73.37 | 98.43 | 111.7 | 0.06 | 5.31 | 6.97 | 0.02 | 3.79 | 95 |

Alumina Spherical Powder BAH Series Specifications

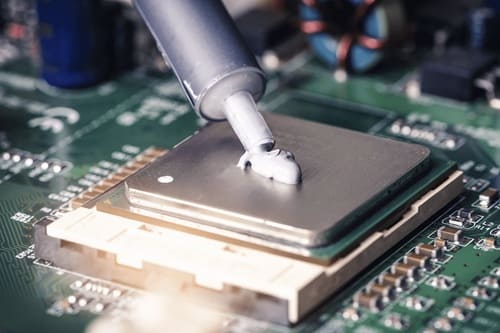

The BAH Series is a product that has been blended and modified, primarily used as thermal interface materials (e.g., thermally conductive silicone pads, thermally conductive greases, thermally conductive potting compounds, thermally conductive tapes, phase change materials, etc.) and thermally conductive engineering plastics (e.g., LED light covers, switch housings, electronic product enclosures, and heat dissipation components for electrical products). We can provide different types of modified products based on specific application needs.

| Properties | Unit | BAH-2H4 | BAH-5H4 | BAH-10H4 | BAH-20H4 | BAH-40H4 | BAH-70H4 | BAH-90H4 | BAH-120H4 | |

| Particle Size | D10 | μm | 0.71 | 2.33 | 4.18 | 11.96 | 24.92 | 44.28 | 53.44 | 94.33 |

| D50 | μm | 2.15 | 5.59 | 10.03 | 21.56 | 42.49 | 71.45 | 88.27 | 122.18 | |

| D90 | μm | 4.24 | 9.38 | 18.46 | 36.81 | 65.99 | 106.5 | 133.24 | 168.18 | |

| Specific Surface Area | m2/g | 0.65 | 0.17 | 0.09 | 0.07 | 0.05 | 0.02 | 0.01 | 0.01 | |

| Electricity Conductivity | μS/cm | 1.76 | 1.15 | 1.05 | 0.94 | 1.72 | 1.78 | 2.87 | 1.93 | |

| PH Value | — | 7.13 | 7.23 | 6.79 | 6.75 | 7.00 | 6.98 | 6.78 | 7.13 | |

| Moisture | % | 0.04 | 0.04 | 0.04 | 0.04 | 0.03 | 0.04 | 0.04 | 0.04 | |

| True Density | g/cm3 | 3.62 | 3.78 | 3.78 | 3.81 | 3.77 | 3.83 | 3.83 | 3.79 | |

| Spheroidization Rate | % | 96 | 96 | 96 | 96 | 96 | 96 | 95 | 95 | |

| Chemical Composition | Al2O3 | % | 99.12 | 99.51 | 99.53 | 99.63 | 99.73 | 99.72 | 99.71 | 99.73 |

| SiO2 | ppm | 432 | 453 | 312 | 387 | 396 | 376 | 384 | 359 | |

| Fe2O3 | ppm | 175 | 165 | 134 | 153 | 173 | 164 | 176 | 181 | |

| Na2O | ppm | 105 | 103 | 116 | 115 | 172 | 107 | 113 | 106 | |

Alumina Spherical Powder BAM Series Specifications

The BAM series is manufactured by blending the BAK series with different particle sizes to enhance thermal conduction efficiency. The BAM has a better filling capacity, a more optimized particle distribution, and effectively improves the heat transfer efficiency of the thermal conduction channels.

| Product | Particle Size(μm) | Specific Surface Area | Electricity Conductivity | PH | Moisture | True Density | Spheroidization Rate | Al2O3 | SiO2 | Fe2O3 | Na2O | ||

| D10 | D50 | D90 | ㎡ /g | μS/cm | – | % | g/cm³ | % | % | ppm | ppm | ppm | |

| BAM-5M5 | 1.5 | 5.73 | 11.08 | 0.36 | 4.23 | 7.58 | 0.03 | 3.76 | 96 | 99.93 | 415 | 174 | 111 |

| BAM-10M6 | 1.492 | 8.91 | 17.88 | 0.26 | 3.74 | 7.59 | 0.03 | 3.8 | 96 | 99.94 | 333 | 163 | 104 |

Alumina Powder Fine Particle Solutions

Spherical Powder

Spherical Alumina Powder is a high-performance Al2O3 material with perfectly spherical particles, high thermal conductivity, and low surface roughness. The products include the HMBAK series, HM Top Cut series, HMBAH series, and HMBAM series.

Alumina Spherical Powder Advantages

- Outstanding Flowability

- High Packing Density

- Particle Uniformity

- High Purity and Chemical Stability

- Superior Mechanical Properties

- Efficient Processing

Alumina Spherical Powder Applications

- Advanced Ceramics: Produces strong, durable ceramics.

- Thermal Spray Coatings: Creates heat- and corrosion-resistant coatings.

- Catalyst Supports: Used in chemical and environmental catalysts.

- Abrasive Manufacturing: Makes grinding wheels and polishing materials.

- Composite Materials: Boosts heat resistance.

- Additive Manufacturing: 3D prints precise ceramic parts.

Alumina Spherical Powder Packaging

The Alumina Spherical Powder is carefully placed in wooden cases or cartons with additional support from soft materials to prevent any shifting during transportation. This packaging method guarantees the integrity of the products throughout the delivery process.

Download

Get A Quote

We will check and get back to you in 24 hours.