Alumina Foam

Alumina Foam

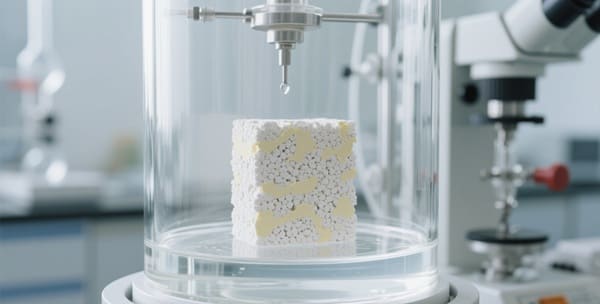

Alumina Foam is a highly porous ceramic material made from aluminum oxide (Al₂O₃), known for its excellent thermal stability, corrosion resistance, and lightweight structure. With its uniform open-cell network, it is commonly used in high-temperature filtration applications, particularly in metal casting to trap impurities and enhance product purity. Its insulating properties and resistance to chemical attack also make it suitable for use in catalyst supports, thermal insulators, and high-temperature furnace linings. we can supply high-quality alumina foam with various specifications and competitive prices, offering customized solutions to meet specific requirements.

Or email us at sales@heegermaterials.com.Alumina Foam Data Sheet

| Product | Large-Plate alumina foam | Small-Block alumina foam |

| Chemical Composition | Al2O3 | |

| Porosity (%) | 80–90% | |

| Pore Density (PPI) | 10PPI–70PPI | |

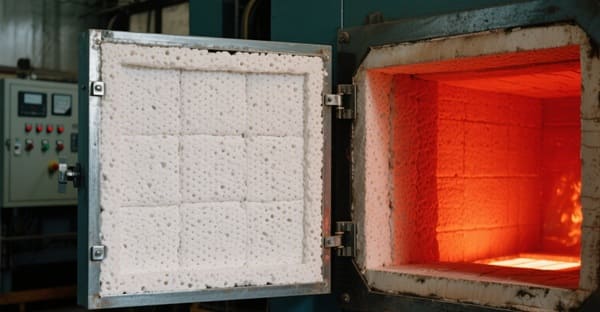

| Operating Temperature (°C) | ≤1100°C | |

| Room Temperature Bending Strength (MPa) | 0.6 MPa | |

| Room Temperature Compression Strength (MPa) | 0.8 MPa | |

| Thermal Shock Resistance | 750°C to room temperature: 6 times | 1100°C to room temperature: 5 times |

| Bulk Density (g/cm³) | 0.35–0.45 g/cm³ | 0.4–0.5 g/cm³ |

Alumina Foam Description

Alumina (Al2O3) Ceramic Foam Filter offers excellent thermal stability, chemical resistance, and filtration efficiency, making it a trusted choice for removing inclusions from molten aluminum and its alloys. These filters are available in various sizes and pore densities to suit different casting methods, including continuous, semi-continuous, and sand casting. Their open-cell structure promotes smooth metal flow while trapping oxides, slag, and non-metallic inclusions. In addition to aluminum casting, alumina foam is also used in gas purification, heat insulation, and catalytic support applications.

Alumina Foam Specification

| Specification | Ceramic Filter Radius (R) | Ceramic Filter Height (H) | Edge Thickness (T) |

|---|---|---|---|

| Φ40×20 | 20 | 20 | 2 |

| Φ50×20 | 25 | 20 | 2 |

| Φ65×20 | 32.5 | 20 | 2 |

| Φ80×20 | 40 | 20 | 2 |

| Φ100×20 | 50 | 20 | 2 |

| Φ40×25 | 20 | 25 | 2 |

| Φ50×25 | 25 | 25 | 2 |

| Φ65×25 | 32.5 | 25 | 2 |

| Φ80×25 | 40 | 25 | 2 |

| Φ100×25 | 50 | 25 | 2 |

Note:

- Restrictions: Depth greater than 5mm of missing angles/edges or deformation with curvature exceeding 2mm is not allowed.Advantages

- Custom Dimensions: Sizes can be customized to specific requirements.

- Tolerances: Ceramic filter radius R tolerance is 0.75–0.25, height H tolerance is 1.5–0.5, and edge thickness T tolerance is 0.5–0.5.

Alumina Foam Usage Precautions

- It is recommended to use an open pouring system to prevent air entrapment.

- Avoid the direct impact of molten metal on the filter. If unavoidable, the pouring height should not exceed 300mm.

- Preheat the filter together with the riser or pouring spout to prevent the steel liquid from solidifying and blocking the filter.

- Before usage, remove surface slag from the filter with air blowing.

Alumina Foam Advantages

- Excellent Thermal Shock Resistance: Alumina foam maintains its structural integrity under rapid temperature changes, making it ideal for high-temperature metal filtration environments.

- High Porosity and Filtration Efficiency: The open-cell structure allows for effective removal of inclusions and impurities from molten metals, improving the final product’s mechanical and surface properties.

- Superior Chemical Stability: Resistant to corrosion and chemical attack from molten aluminum and its alloys, ensuring long service life and consistent performance.

- Lightweight and Durable: Despite its robust structure, alumina foam is lightweight, easy to handle, and install, reducing maintenance and operational costs.

- Multifunctional Applications: Beyond metal filtration, it can also be used for gas dispersion, catalyst carriers, thermal insulation, and sound absorption in various industrial processes.

Alumina Foam Applications

- Molten Metal Filtration: Used extensively in the filtration of molten aluminum and its alloys during casting processes to remove inclusions and improve product quality.

- High-Temperature Gas Filtration: Ideal for filtering hot gases in metallurgy and chemical industries due to its thermal stability and corrosion resistance.

- Catalyst Carrier: Serves as an efficient carrier for catalysts in petrochemical and environmental applications, offering high surface area and chemical inertness.

- Sound Absorption and Thermal Insulation: Applied in industrial furnaces and engines to absorb sound and provide thermal insulation in extreme conditions.

- Non-Ferrous Metal Casting: Utilized in precision casting of non-ferrous metals to ensure smooth surface finishes and enhance structural integrity of final products.

Alumina Foam Properties

Alumina Ceramic Packaging

Alumina ceramic products are typically packaged in vacuum-sealed bags to prevent moisture or contamination and wrapped with foam to cushion vibrations and impacts during transport, ensuring the quality of products in their original condition.

Download

Get A Quote

We will check and get back to you in 24 hours.