Zirconia Ceramics: Precision Applications in High-Tech Sectors

Introduction

Zirconia ceramics (ZrO₂), or zirconium dioxide, are advanced materials prized for their mechanical strength, thermal stability, and electrical insulation. Available in standard (95% ZrO₂) and toughened (85% ZrO₂) forms, these ceramics excel in high-tech applications across electronics, aerospace, biomedical, and industrial sectors. This article explores zirconia’s precision applications, supported by a table linking properties to their uses.

Applications of Zirconia Ceramics

Zirconia ceramics are utilized across diverse sectors due to their unique properties. Below are their key applications:

- 5G Antennas (Electronics): Enable high-frequency signal transmission.

- Fingerprint Sensors (Electronics): Enhance detection accuracy in security systems.

- Circuit Substrates (Electronics): Ensure electrical insulation in high-power devices.

- Turbine Blade Coatings (Aerospace): Protect against extreme temperature shifts.

- Heat Shields (Aerospace): Withstand mechanical stress in high-speed flight.

- Engine Components (Aerospace): Support high-load structural parts.

- Dental Crowns (Biomedical): Provide durability in oral environments.

- Hip Replacements (Biomedical): Support load-bearing implants.

- Surgical Scalpels (Biomedical): Maintain sharpness through sterilization.

- Cutting Blades (Industrial): Deliver precision in manufacturing.

- Pump Valves (Industrial): Resist corrosion in chemical processing.

- High-Load Bearings (Industrial): Endure heavy mechanical loads.

Performance of Zirconia Ceramics Across Industries

The table below connects key properties of zirconia ceramics to their applications across electronics, aerospace, biomedical, and industrial sectors.

| Application | Zirconia Type | Key Property | Typical Value | Why It Matters |

| 5G Antennas | Standard (95% ZrO₂) | Dielectric Strength | 33 kV/mm | Ensures signal clarity in high-frequency systems. |

| Fingerprint Sensors | Standard (95% ZrO₂) | Dielectric Constant | 11 (1 MHz) | Boosts sensitivity for accurate detection. |

| Circuit Substrates | Standard & Toughened (95%, 85% ZrO₂) | Volume Resistivity | >10¹³ ohm-cm | Prevents electrical leakage in power systems. |

| Turbine Blade Coatings | Toughened (85% ZrO₂) | Thermal Shock Resistance | 450°C | Endures rapid temperature changes in engines. |

| Heat Shields | Standard (95% ZrO₂) | Compressive Strength | 2580 MPa | Resists stress during high-speed flight. |

| Engine Components | Toughened (85% ZrO₂) | Young’s Modulus | 337 GPa | Provides stiffness for structural reliability. |

| Dental Crowns | Standard (95% ZrO₂) | Fracture Toughness | 4–5 MPa m¹/² | Withstands chewing forces in oral applications. |

| Hip Replacements | Standard (95% ZrO₂) | Compressive Strength | 2580 MPa | Supports load-bearing in orthopedic implants. |

| Surgical Scalpels | Toughened (85% ZrO₂) | Thermal Shock Resistance | 450°C | Maintains integrity during sterilization. |

| Cutting Blades | Toughened (85% ZrO₂) | Vickers Hardness | 16.0 GPa | Ensures wear resistance for precision cutting. |

| Pump Valves | Standard & Toughened (95%, 85% ZrO₂) | Weight Loss in H₂SO₄ | 0.46 mg/cm² | Resists corrosion in chemical environments. |

| High-Load Bearings | Toughened (85% ZrO₂) | Young’s Modulus | 337 GPa | Resists deformation under heavy loads. |

Table Notes:

- Values are based on typical zirconia properties.

- Properties like dielectric strength and hardness ensure precision and reliability across sectors.

Conclusion

Zirconia ceramics, in standard (95% ZrO₂) and toughened (85% ZrO₂) forms, are critical for precision applications in electronics, aerospace, biomedical, and industrial sectors. Their mechanical strength, thermal stability, and electrical insulation drive innovation in high-tech environments.

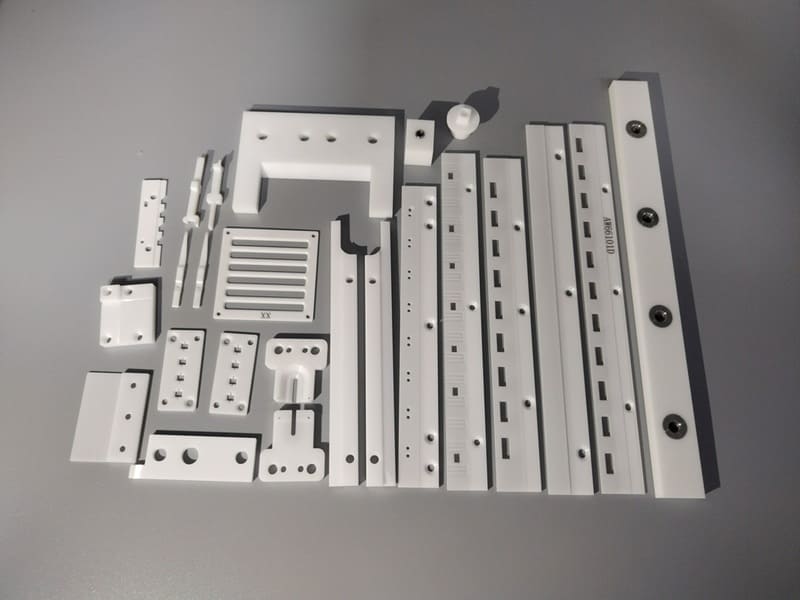

Advanced Ceramics Hub is a leading manufacturer and supplier of high-quality zirconia ceramic products in forms of plates, sheets, rods, tubes, crucibles, substrates, and customized parts, offering customized solutions for various industrial and research applications.